Inner ring burner cap of gas stove burner

A technology of gas cooker and inner ring fire, which is applied in the direction of gas fuel burner, burner, combustion method, etc., which can solve the problems of hard-to-cook food, excessive firepower of the outer ring, and food paste, so as to solve the problem of insufficient firepower and stable burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

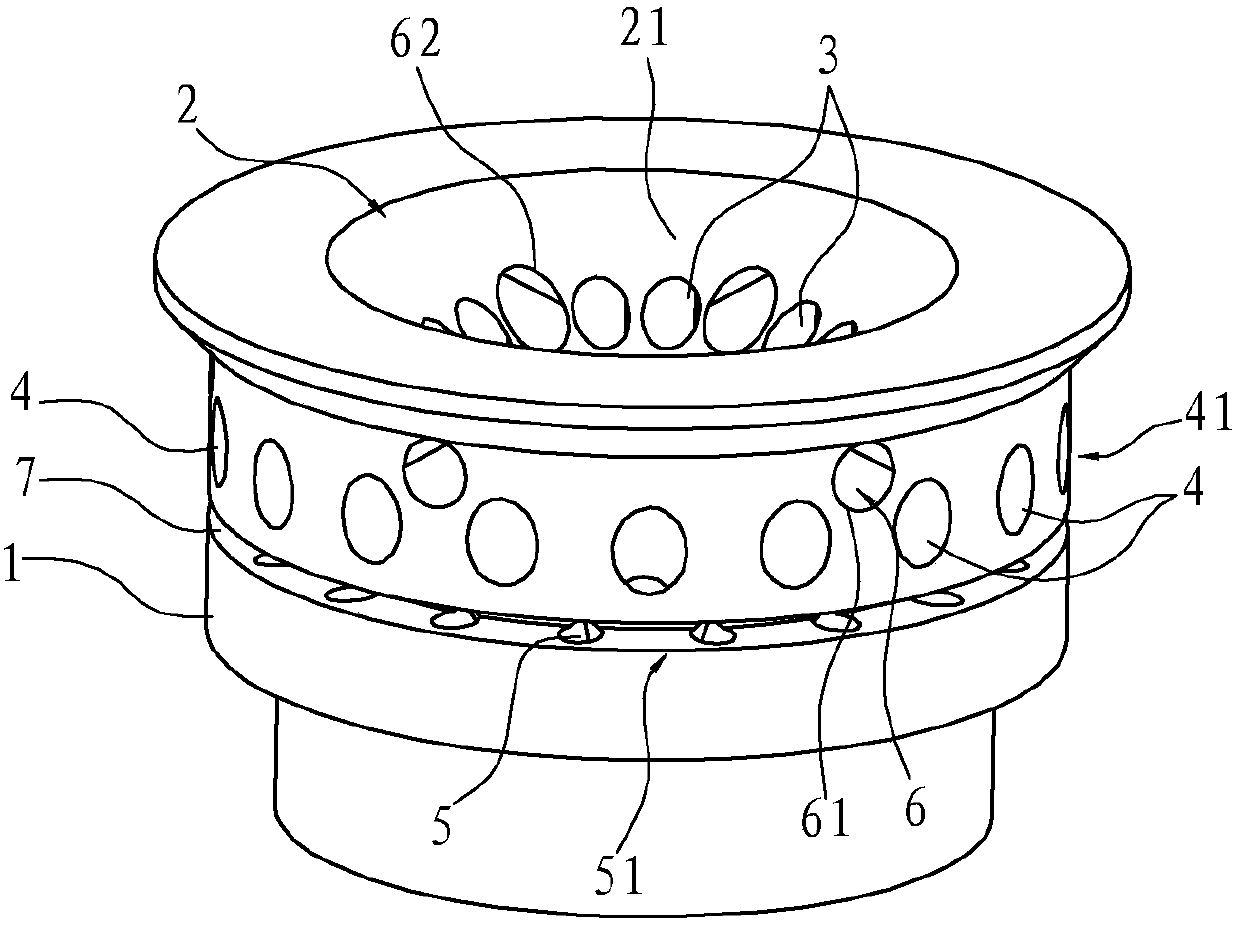

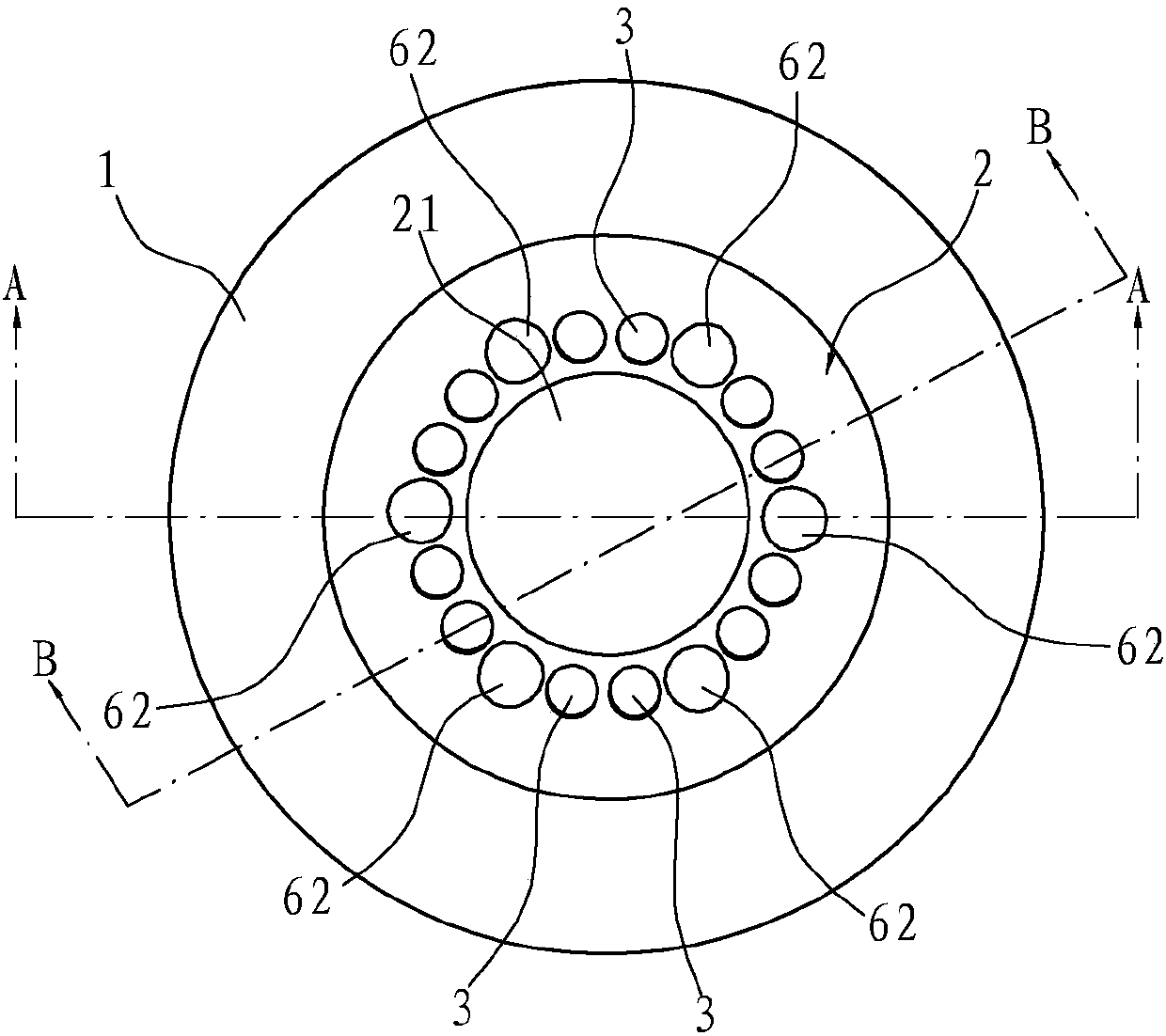

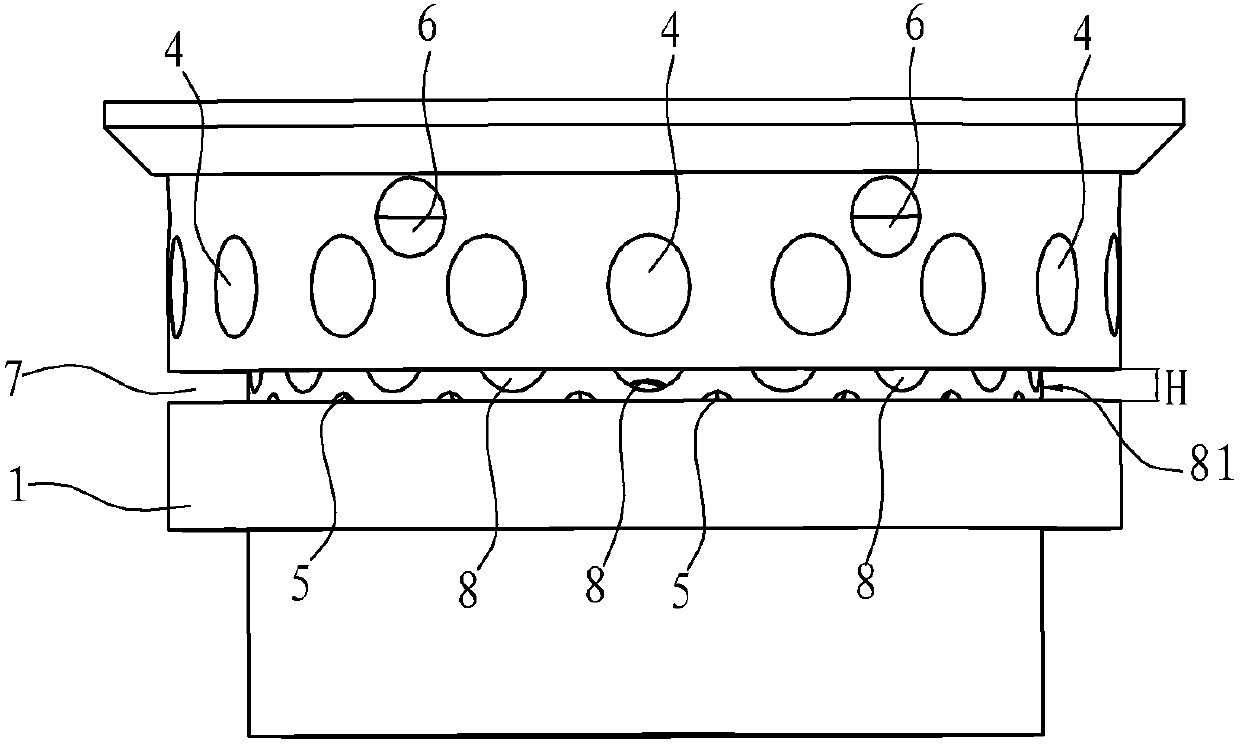

[0023] Such as Figure 1-7 As shown, an inner ring fire cover of a gas cooker burner includes a hollow cylinder-shaped fire cover body 1, and the fire cover body 1 forms an air mixing chamber 11 by a top wall and a side peripheral wall extending downward from the edge of the top wall. The outer wall of the fire cover body 1 is provided with a fire hole communicating with the gas mixing chamber 11 . Further, the top wall of the fire cover body 1 is recessed inward to form a top flame area 2 , and the fire outlet includes a top fire outlet 3 disposed at the depression 21 . In order to make the top flame area 2 burn evenly, in this embodiment, the depression 21 is in the shape of a rounded table, and the top fire outlet 3 is arranged at the lower end of the side wall of the depression 21 along the circumferential direction, and the center axis o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap