Bearing airtightness detector

A technology of air tightness and detector, which is applied in the direction of using liquid/vacuum for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc., can solve problems such as failure to detect bearings, and achieve fast detection speed and high accuracy. , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

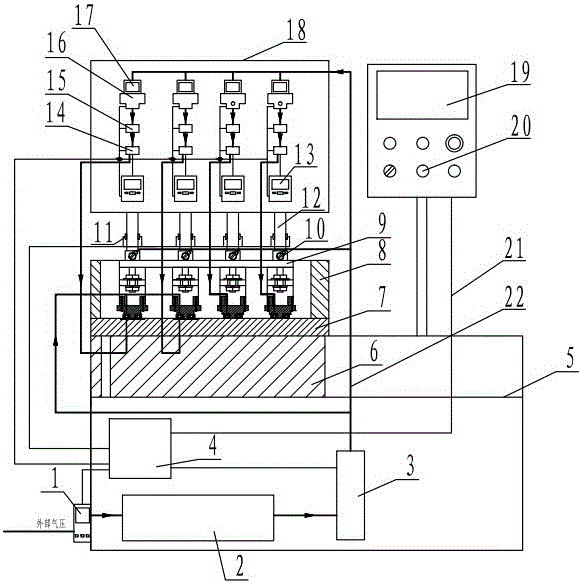

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] An air source pressure valve 1, a cylinder 2, an electromagnetic reversing valve 3, and a PLC controller terminal 4 are installed in the stand 5.

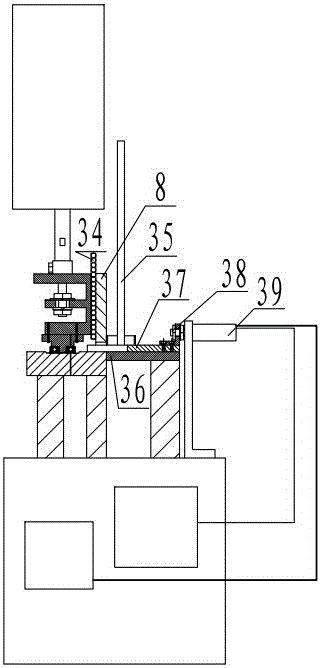

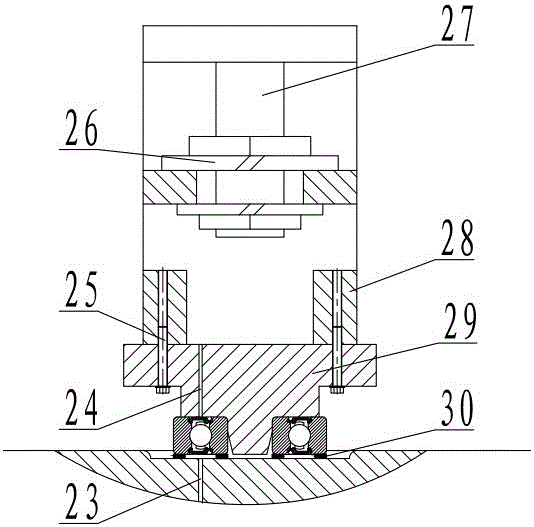

[0014] Lower formwork 6, lower formwork 7, upper formwork 8, upper formwork 9 and fixed platform 18 are fixedly installed successively on the platform 5, touch screen 19 with button 20, fixed platform is connected with air pressure joint 10, air pressure control valve 11 The trachea 12 is fixed on the upper template 9 .

[0015] The detection and display mechanism consists of more than two sets of measuring displays 13, pressure reducing valves 14, pressure maintaining valves 15, pressure transmitters 16 and pressure transmitter displays 17 that are installed in the fixed table 18 and are connected to each other with signal lines 21.

[0016] More than one group of detection station mechanisms are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com