Iterative ultrasonic tomography method for axial flow field imaging in pipeline

An ultrasonic tomography and pipeline technology, applied in the field of information science, can solve the problems of low imaging resolution at the axis of the pipeline, great influence on measurement results, and great influence on measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

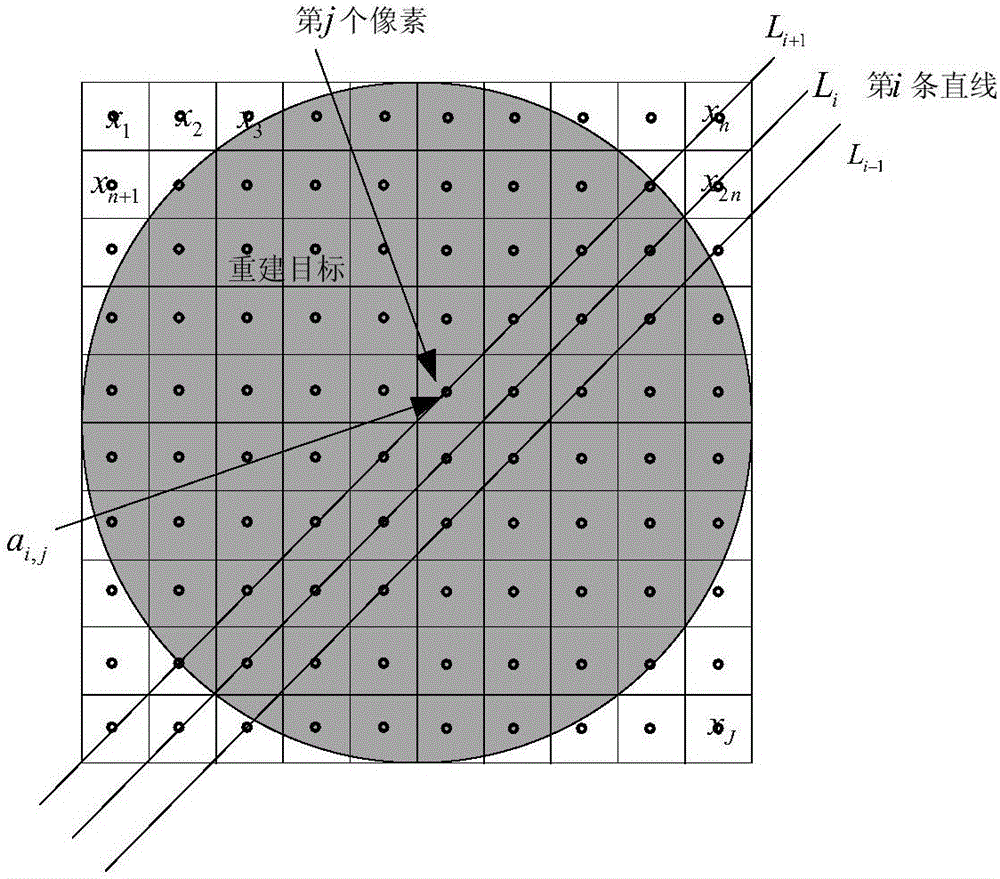

[0047] An iterative ultrasonic tomography method for imaging an axial flow field in a pipeline, comprising the following steps:

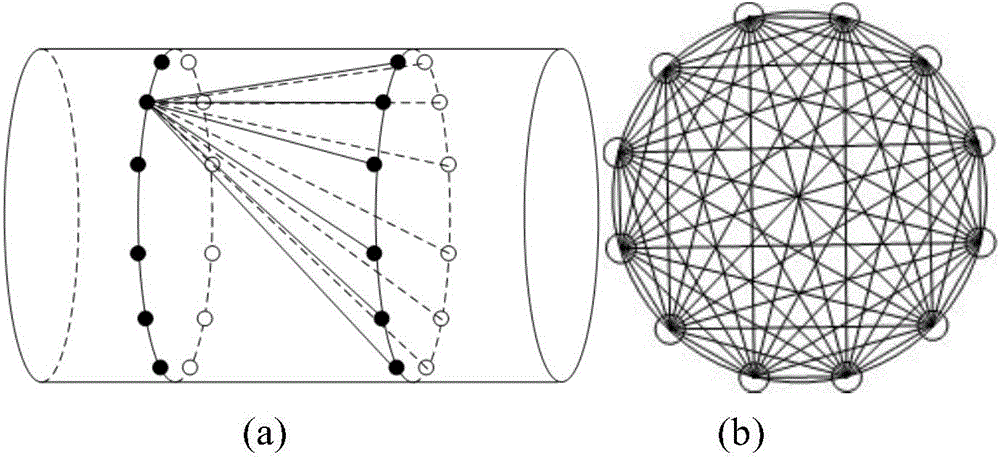

[0048] Step 1: Refer to figure 1 , taking a pipe with a diameter of 500mm as an example, process sensor mounting holes on two cross-sections with an upstream and downstream distance of 500mm. Considering the size limitation, out of compromise considerations, 12 transceiver integrated ultrasonic sensors are installed on each cross section. The number of probes in this layout method can be added or deleted, and the specific number can be changed according to the requirements of pipe diameter, sensor size and imaging resolution in actual applications.

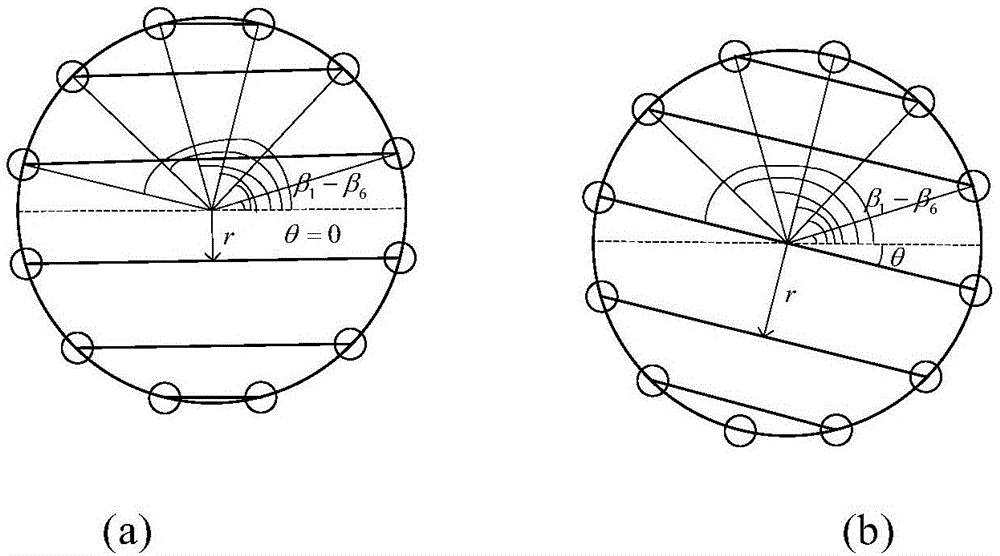

[0049] Step 2: Fabricate an ultrasonic sensor with a loud beam angle for transmitting and receiving ultrasonic signals. The spatial orientation and beam angle of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com