Liquid crystal display panel

A liquid crystal display panel, display area technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of loss, installation module structure design, array substrate and color filter substrate separation, etc., to achieve the effect of increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

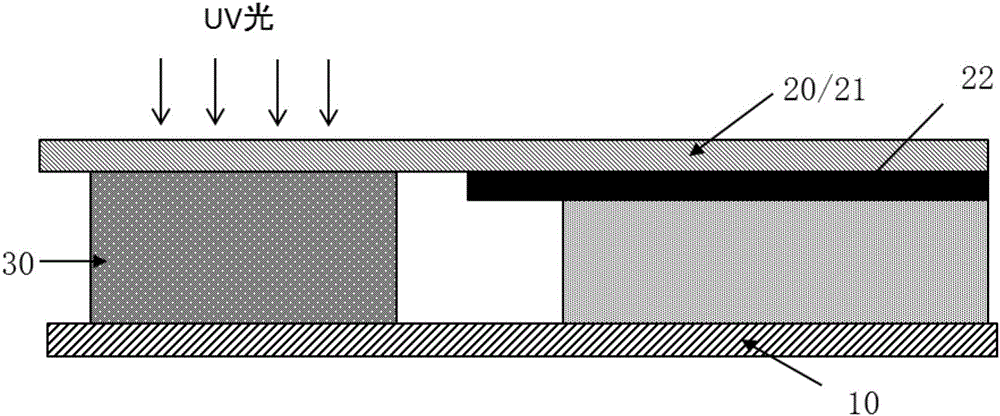

[0020] Liquid crystal display panel of the present invention, as image 3 and Figure 4 As shown, the liquid crystal display panel includes an array substrate 1 and a color filter substrate 2 arranged oppositely, and a liquid crystal (not shown) filled between the array substrate 1 and the color filter substrate 2 . The two substrates are glued together by a frame glue 3 . The liquid crystal display panel is provided with a display area 5 and a peripheral area. The frame glue 3 is arranged between the array substrate 1 and the color filter substrate 3 and is located in the peripheral area.

[0021] The color filter substrate 2 is provided with a glass substrate 21 and a black matrix 21 located under the glass substrate 21 . Part of the black matrix 21 is located in the peripheral area.

[0022] In the peripheral area, the color filter substrate 2 is provided with a black matrix 21 . At the position where the sealant 2 is coated, the black matrix 21 is provided with a plural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com