Large power borehole pump double-side helical gear engagement transmission system bearing analysis method

A force analysis and transmission system technology, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

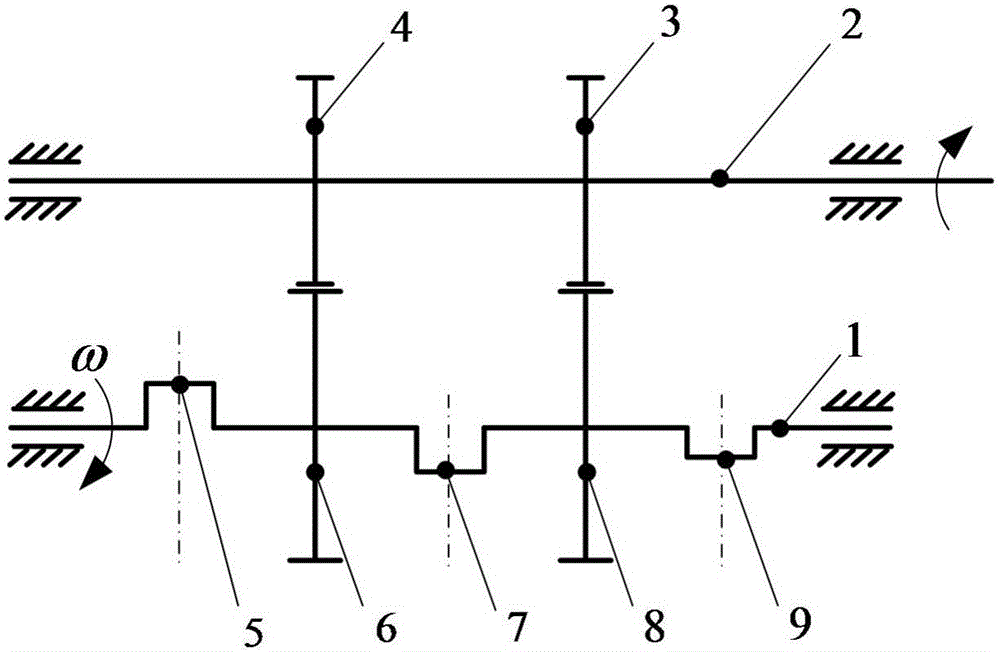

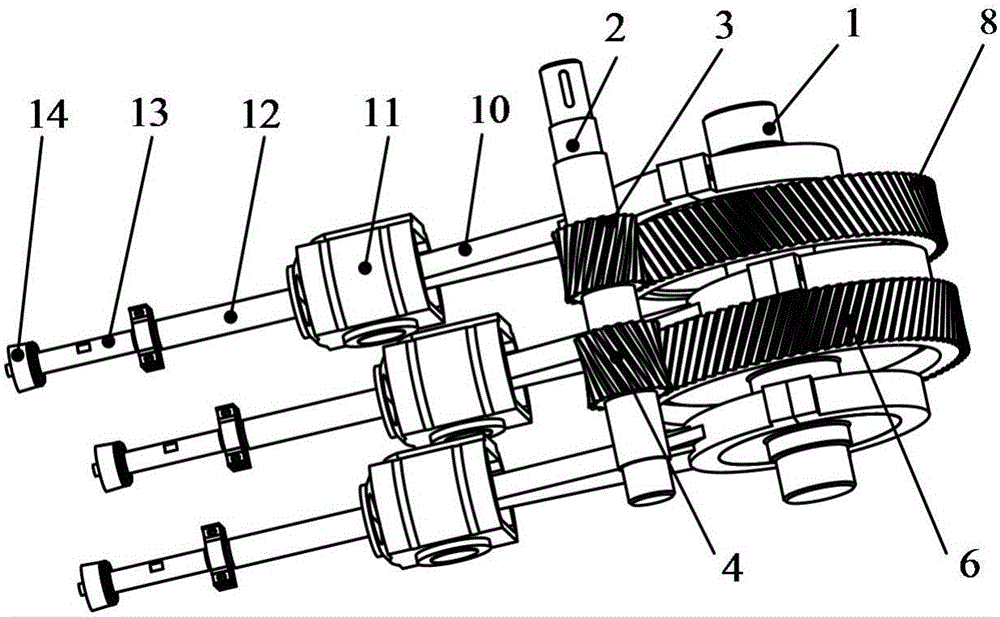

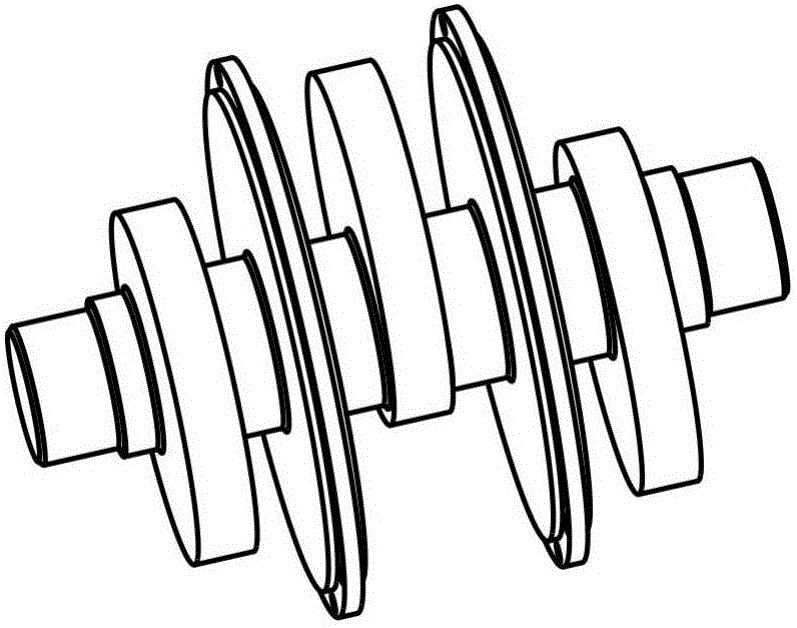

[0090] The principle of double-sided helical gear meshing transmission system of high-power drilling pump is as follows: figure 1 As shown, the power is input from the right end of the drive shaft, and the crankshaft and drive shaft are shown as Figure 3 ~ Figure 4 shown.

[0091] 1) Kinematic relationship of the crank-link mechanism

[0092] The displacement, velocity and acceleration of the piston can be determined from the geometric relationship and kinematic relationship of the crank-link mechanism, such as Figure 5 As shown, taking the positive direction of the X-axis as the positive direction, the displacement origin of the piston is at the rear dead center 5-1, and the crankshaft rotation angle Count from the front dead center, that is, φ=0 at this time, S=2R, and the crankshaft rotates clockwise. In order to facilitate the calculation, it is considered that the crankshaft rotates at a constant speed. It can be known from theoretical derivation that the calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com