Safety guide intelligent tour-spot inspection system

A kind of inspection and intelligent technology, applied in the field of safety-oriented intelligent inspection point system, can solve the problems of being unable to grasp the on-site equipment and inspection results in real time, affecting its own safety, and low efficiency, so as to achieve convenient discovery and timely processing, and guarantee The effects of safe production and improved positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

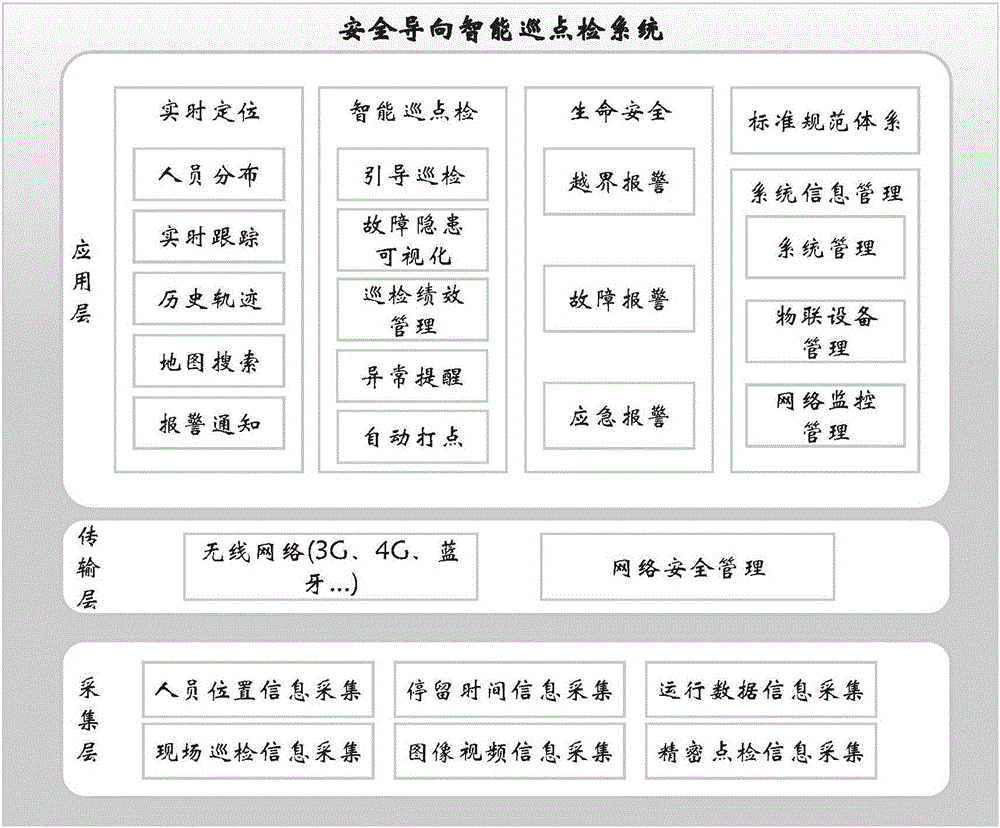

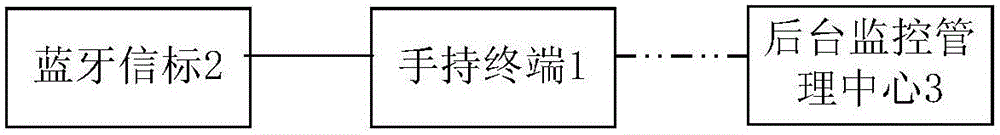

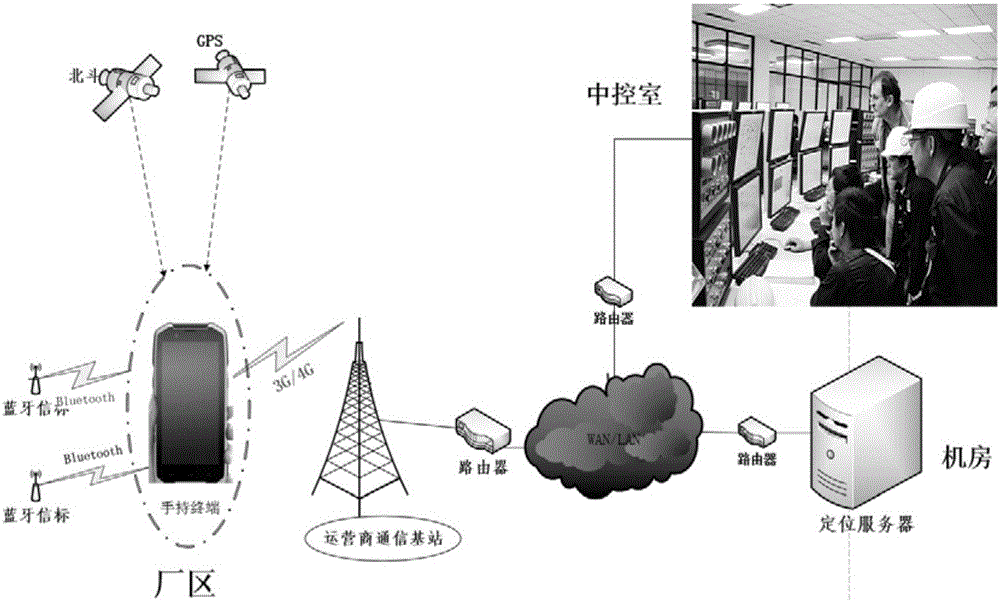

[0039] Such as figure 1 As shown, the functional architecture of the security-oriented intelligent patrol inspection system according to the embodiment of the present invention is mainly divided into an acquisition layer, a transmission layer and an application layer. Among them, the collection layer mainly includes the collection of personnel location information, on-site inspection information collection, equipment operation data collection, etc., through the deployment of intelligent inspection terminals to realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com