Exoskeleton type wounded finger rehabilitation robot

A rehabilitation robot and exoskeleton technology, applied in passive exercise equipment, physical therapy, etc., can solve the problems of inability to directly feedback the rehabilitation effect, long rehabilitation time, high labor intensity, etc., to improve the rehabilitation effect, simple and reliable tensioning mechanism , the effect of avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

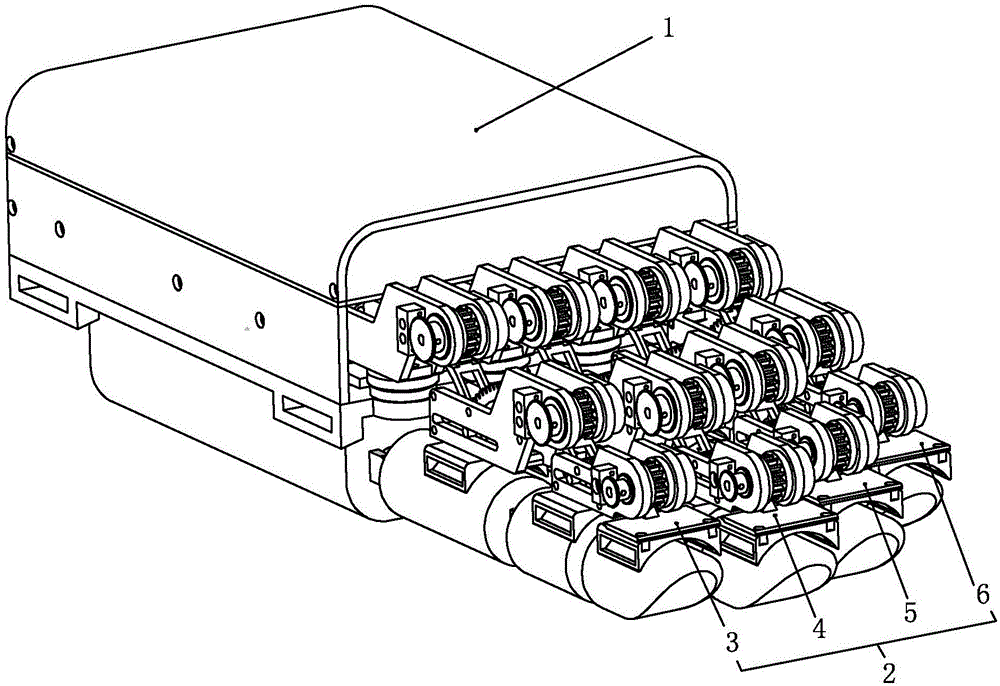

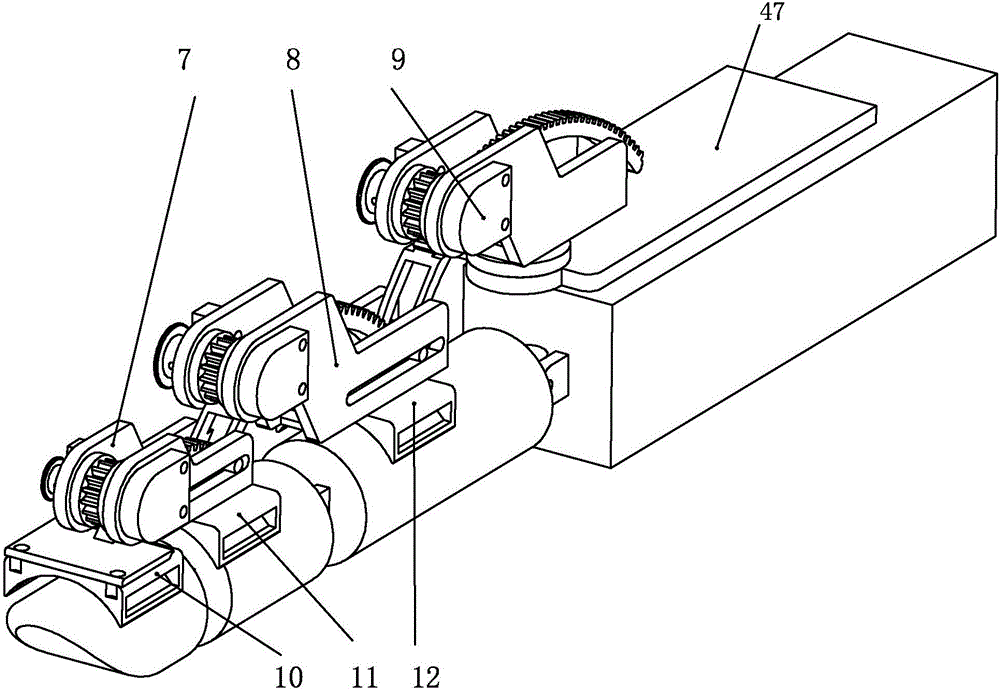

[0035] Specific implementation mode one: as Figure 1-12 As shown, the exoskeleton type trauma finger rehabilitation robot of this embodiment includes an artificial muscle drive module 1 and an exoskeleton execution module 2, and the exoskeleton execution module 2 includes an index finger exoskeleton 3, a middle finger exoskeleton 4, a ring finger exoskeleton 5 and The little finger exoskeleton 6; the index finger exoskeleton 3, the middle finger exoskeleton 4, the ring finger exoskeleton 5 and the little finger exoskeleton 6 are mainly composed of the distal interphalangeal joint unit 7, the proximal interphalangeal joint unit 8 and the metacarpophalangeal joint unit 9. The distal interphalangeal joint unit 7, the proximal interphalangeal joint unit 8, and the metacarpophalangeal joint unit 9 are respectively fixed on the corresponding first finger cuff 10, second finger cuff 11, and third finger cuff 12 by screws, and the index finger exoskeleton The metacarpophalangeal join...

specific Embodiment approach 2

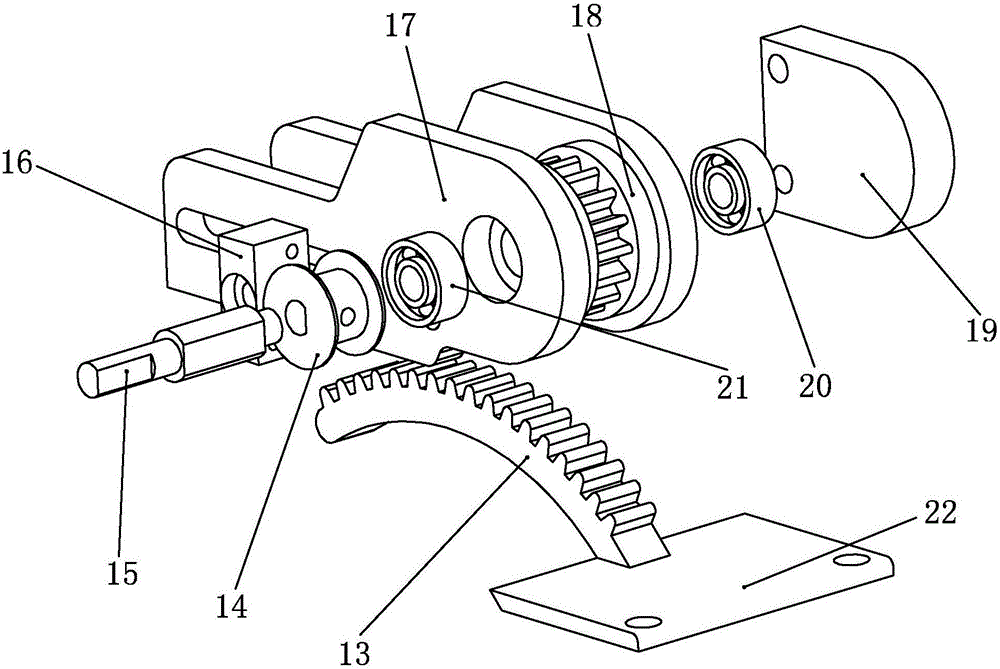

[0038] Specific implementation mode two: as figure 1 and figure 2 As shown, the distal interphalangeal joint unit 7 in this embodiment includes a first joint arc rack 13, a first joint pulley 14, a first joint shaft 15, a first joint spring baffle 16, a first joint support 17. The first joint measuring gear 18, the first joint angular displacement sensor 19 and the first connecting plate 22; one end of the first joint arc-shaped rack 13 is welded together with the first connecting plate 22, and the first connecting plate 22 is connected to the corresponding The finger cots 10 are fixedly connected, and the first joint support 17 is fixedly connected with the corresponding finger cots 11 by screws. The two side walls of the first joint support 17 are all processed with sliding grooves along its length direction, and the first joint spring baffle 16 And the first joint pulley 14 is fixed on the side wall of the first joint support 17 by screws, the first joint angular displace...

specific Embodiment approach 3

[0039] Specific implementation mode three: as figure 1 and image 3 As shown, the proximal interphalangeal joint unit 8 in this embodiment includes a second joint arc rack 23, a second joint adjustment shaft 24, a second joint pulley 28, a second joint shaft 26, and a second joint spring baffle 29. The second joint support 30, the second joint measurement gear 31, the second joint angular displacement sensor 32 and the second joint arc gear support shaft 45; the second joint support 30 is fixed on the upper end surface of the finger cot 12 by screws, the second Both side walls of the two-joint bracket 30 are processed with sliding grooves along its length direction, and one end of the second joint arc rack 23 is installed on the sliding groove of the first joint bracket 17 by the second joint adjustment shaft 24, and the second The joint arc gear support shaft 45 is installed on the second joint support 30, the second joint arc rack 23 is supported on the second joint arc gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com