Method for preparing super-hydrophilic composite PVDF ultrafiltration membrane

A technology of ultra-hydrophilic and ultrafiltration membranes, which is applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of limited improvement of hydrophilicity, decreased membrane separation performance, and unstable membrane performance, etc., to achieve improved Effect of anti-pollution performance and improvement of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1. Immerse the commercial PVDF membrane in absolute ethanol for 24 hours, and then repeatedly wash with deionized water to obtain the commercial PVDF membrane after cleaning.

Embodiment 2

[0033] Step 1. Immerse the commercial PVDF membrane in absolute ethanol for 24 hours, and then repeatedly wash with deionized water;

[0034] Step 2. Dissolve 2g / L dopamine into a Tris-HCI buffer solution with a pH of 8.5;

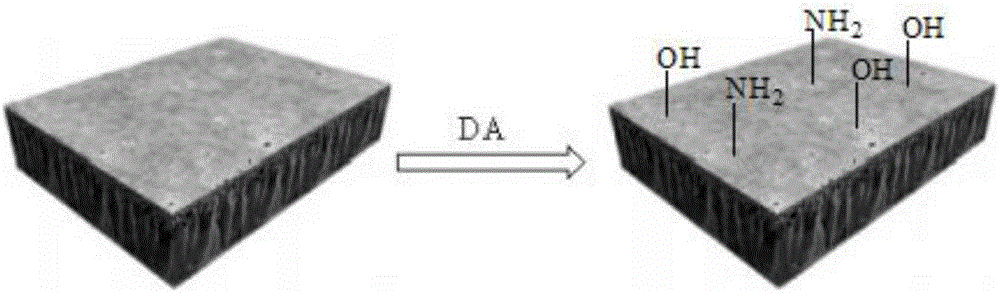

[0035] Step 3. Dip the PVDF membrane cleaned in step 1 into the dopamine solution prepared in step 2, and immerse it at room temperature for 12 hours. The dopamine fully self-polymerizes a polydopamine coating layer on the surface of the PVDF membrane to obtain a polydopamine coating PVDF membrane, the preparation process is shown in 1.

Embodiment 3

[0037] Step 1. Immerse the commercial PVDF membrane in absolute ethanol for 24 hours, and then repeatedly wash with deionized water;

[0038] Step 2. Dissolve 2g / L dopamine into a Tris-HCI buffer solution with a pH of 8.5;

[0039] Step 3. Dip the PVDF membrane cleaned in step 1 into the dopamine solution prepared in step 2, and immerse it at room temperature for 12 hours. The dopamine fully self-polymerizes a polydopamine coating layer on the surface of the PVDF membrane to obtain a polydopamine coating PVDF membrane;

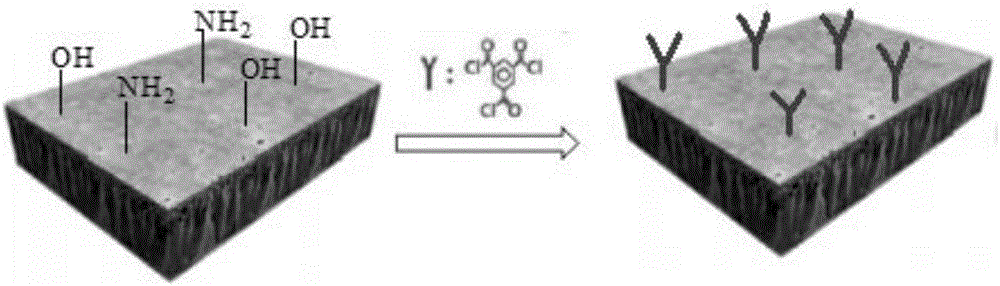

[0040] Step 4. Dissolve trimesoyl chloride into Isobar G In the solution, trimesoyl chloride in Isobar G The weight concentration in the solution is 0.5wt%;

[0041] Step 5. Immerse the PVDF membrane with self-polymerized dopamine in step 3 into the Isobar of trimesoyl chloride in step 4. G Soaking in the solution for 60S, trimesoyl chloride can be grafted onto the PVDF membrane from polydopamine; the preparation process is as follows figure 2 Shown

[0042] Step 6. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap