Square battery fixture used for charging and discharging testing

A charge-discharge test, square battery technology, used in clamps, manufacturing tools, etc., can solve the problems of poor heat dissipation effect, easy short circuit of positive and negative electrodes, and achieve good heat dissipation effect, avoid wiring short circuit, and large heat dissipation area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The present invention provides a square battery fixture for charge and discharge test aiming at the shortcomings of the existing square battery fixture for charge and discharge test.

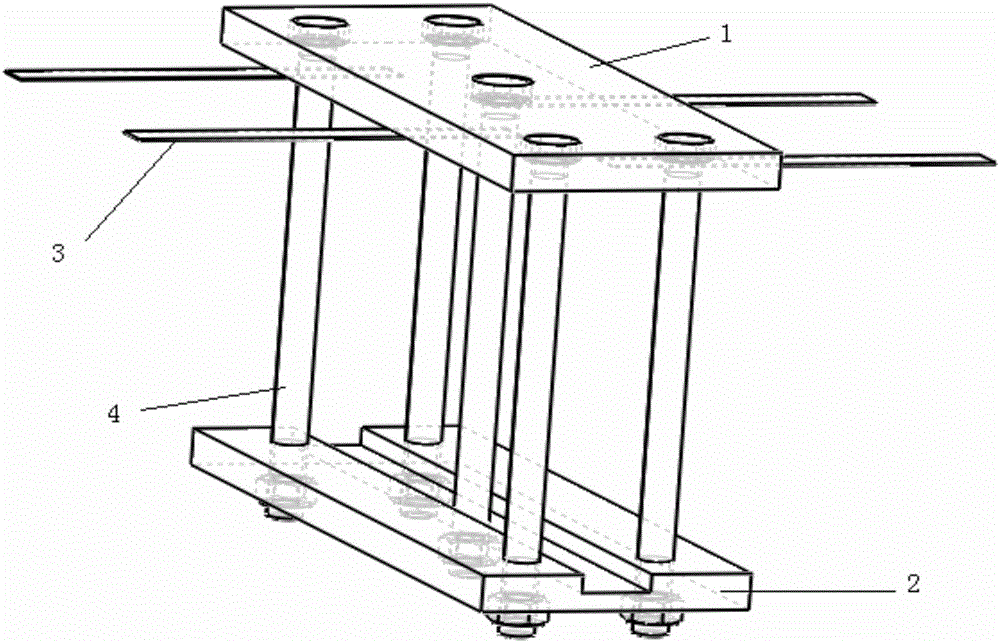

[0018] figure 1 As shown, a square battery fixture for charging and discharging tests, the square battery fixture includes an upper splint 1, a lower splint 2, and five bolts 4 connected between the upper splint 1 and the lower splint 2, the upper splint 1 shown Four pole pieces 3 for testing wiring are arranged on both sides to prevent the short circuit of the two poles of the battery. The upper splint 1 and the lower splint 2 are evenly provided with 5 connecting holes for connecting the bolts 4 .

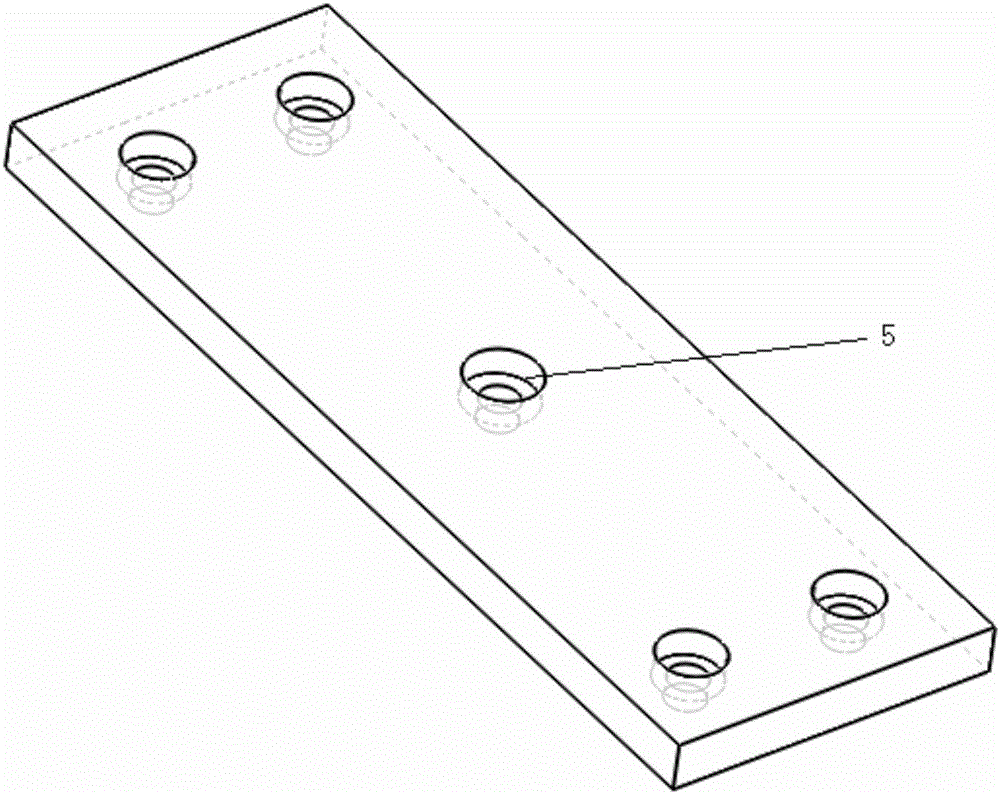

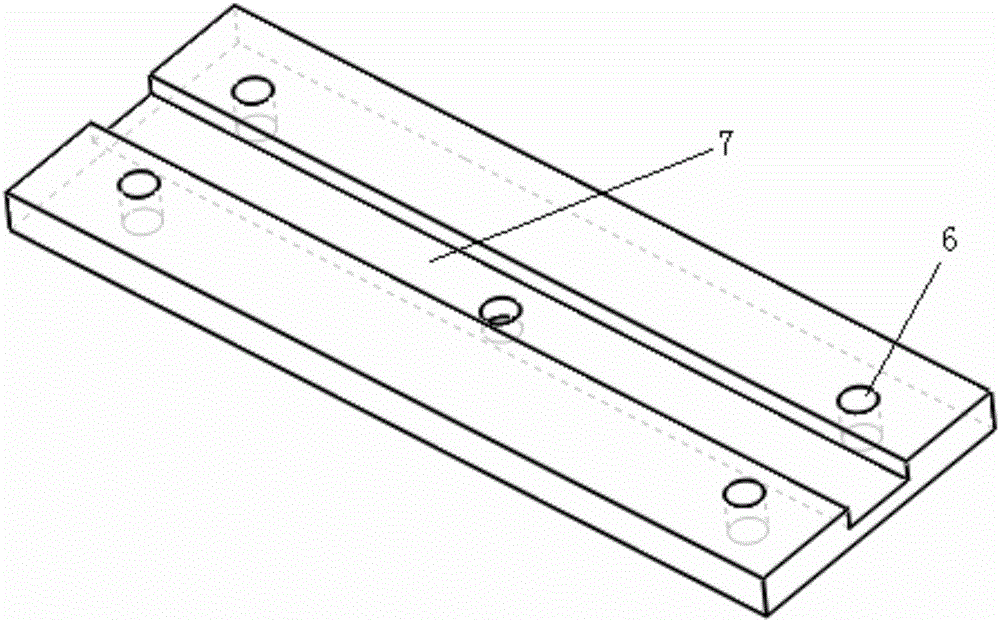

[0019] The connecting holes include several counterbores 5 uniformly arranged on the upper clamping plate 1 and corresponding through holes 6 arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com