Efficient cutting device for bowl-shaped plastic

A technology for cutting equipment and bowl-shaped plastic, applied in the field of plastic parts processing, can solve the problems of labor-intensive, high maintenance cost, wear, etc., and achieve the effects of reducing wear, increasing service life, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

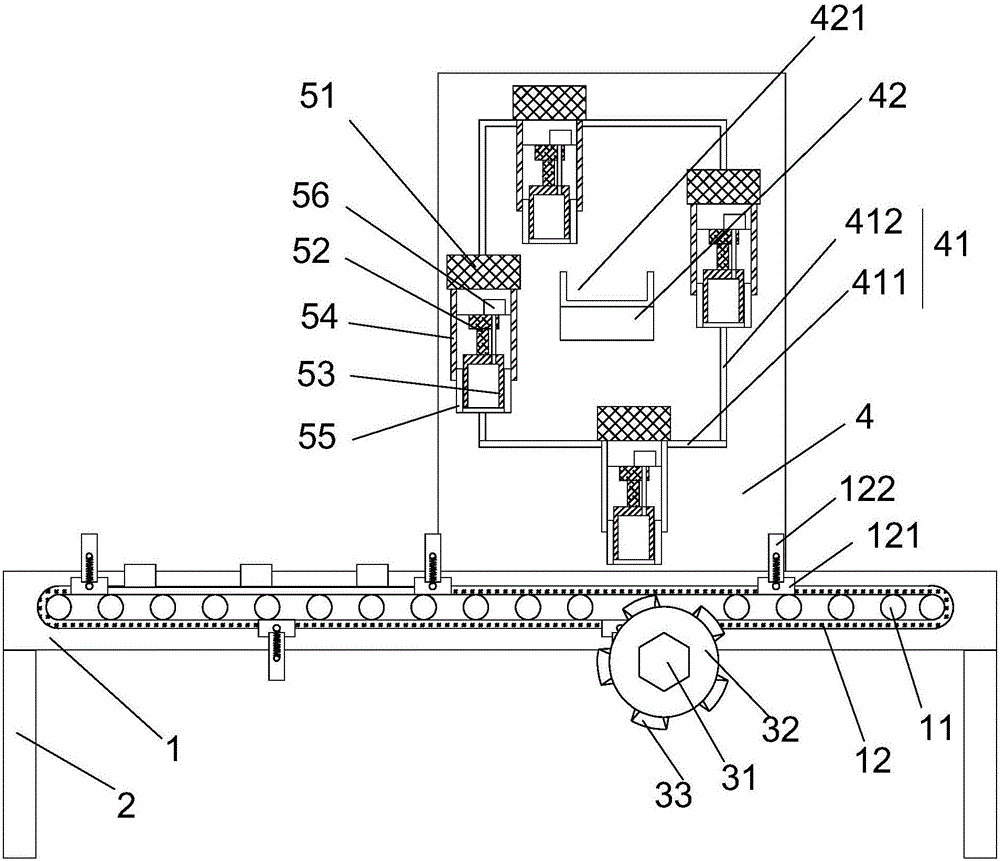

[0019] refer to figure 1 As shown, a kind of high-efficiency cutting equipment for bowl-shaped plastic proposed by the present invention includes frame 1, support column 2, cutting mechanism 3, mounting frame 4 and a plurality of pressing mechanisms;

[0020] The support column 2 is installed on the bottom of the frame 1, the cutting mechanism 3 includes a rotating shaft 31, a supporting cylinder 32 and a plurality of cutting knives 33, the rotating shaft 31 is rotatably installed on the frame 1, the axis of the rotating shaft 31 is horizontal, and the supporting cylinder 32 There is a mounting hole matching the rotating shaft 31 inside, the supporting cylinder 32 is installed on the periphery of the rotating shaft 31 through the mounting hole, the supporting cylinder 32 is provided with a plurality of blade insertion grooves, and the cutting knife 33 is detachably installed in the blade insertion groove;

[0021] A plurality of transmission columns 11 are rotatably installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com