Horizontal well cementation and completion integrated pipe string device for secondary spudding

A technology for cementing and completing wells and horizontal wells, which is applied to wellbore/well valve devices, wellbore/well components, drilling pipes, etc. Reduce processing difficulty and cost, ensure smooth connection, and increase the effect of inner diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

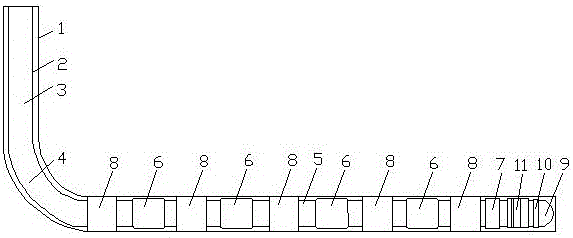

[0038] An integrated cementing and completion pipe string device for two open horizontal wells, including a casing 1, a pipe string 2 inside the casing 1, and the pipe string 2 is composed of a vertical section 3, an inclined section 4 and a horizontal section 5 from top to bottom , a pitching sleeve 6, a pressure differential sleeve 7, an open hole packer 8 and a floating shoe 9 arranged on the horizontal section 5, and also includes a floating hoop 10 and a self-sealing ball seat 11, and there are three open hole packers 8 , between any two adjacent open-hole packers 8, there is a ball sliding sleeve 6, and the string 2 is sequentially connected with the floating shoes 9, floating hoop 10, self-sealing ball seat 11, Differential pressure sliding sleeve 7, open hole packer 8 and pitching sliding sleeve 6.

[0039] This embodiment is the most basic implementation, including a floating hoop and a self-sealing ball seat. The self-sealing ball seat in the prior art is sufficient....

Embodiment 2

[0041] An integrated cementing and completion pipe string device for two open horizontal wells, including a casing 1, a pipe string 2 inside the casing 1, and the pipe string 2 is composed of a vertical section 3, an inclined section 4 and a horizontal section 5 from top to bottom , the pitching sliding sleeve 6, the differential pressure sliding sleeve 7, the open hole packer 8 and the floating shoe 9 arranged on the horizontal section 5, and also includes a floating hoop 10 and a self-sealing ball seat 11, and there are four open hole packers 8 , between any two adjacent open-hole packers 8, there is a ball sliding sleeve 6, and the string 2 is sequentially connected with the floating shoes 9, floating hoop 10, self-sealing ball seat 11, Differential pressure sliding sleeve 7, open hole packer 8 and pitching sliding sleeve 6.

[0042] The outer diameters of the ball-throwing sliding sleeves 6 arranged sequentially along the pipe string 2 from bottom to top are the same, and ...

Embodiment 3

[0045] An integrated cementing and completion pipe string device for two open horizontal wells, including a casing 1, a pipe string 2 inside the casing 1, and the pipe string 2 is composed of a vertical section 3, an inclined section 4 and a horizontal section 5 from top to bottom , the pitching sliding sleeve 6, the differential pressure sliding sleeve 7, the open hole packer 8 and the floating shoe 9 arranged on the horizontal section 5, and also includes a floating hoop 10 and a self-sealing ball seat 11, and there are four open hole packers 8 , between any two adjacent open-hole packers 8, there is a ball sliding sleeve 6, and the string 2 is sequentially connected with the floating shoes 9, floating hoop 10, self-sealing ball seat 11, Differential pressure sliding sleeve 7, open hole packer 8 and pitching sliding sleeve 6.

[0046] The outer diameters of the ball-throwing sliding sleeves 6 arranged sequentially along the pipe string 2 from bottom to top are the same, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com