Dual-opening horizontal well cementation and completion construction method

A construction method and technology for cementing and completing wells, which are applied in wellbore/well components, valve devices for wellbore/wells, earth-moving drilling, etc. and other problems to achieve the effect of ensuring smooth connection, saving gas test cycle, and saving gas test success.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

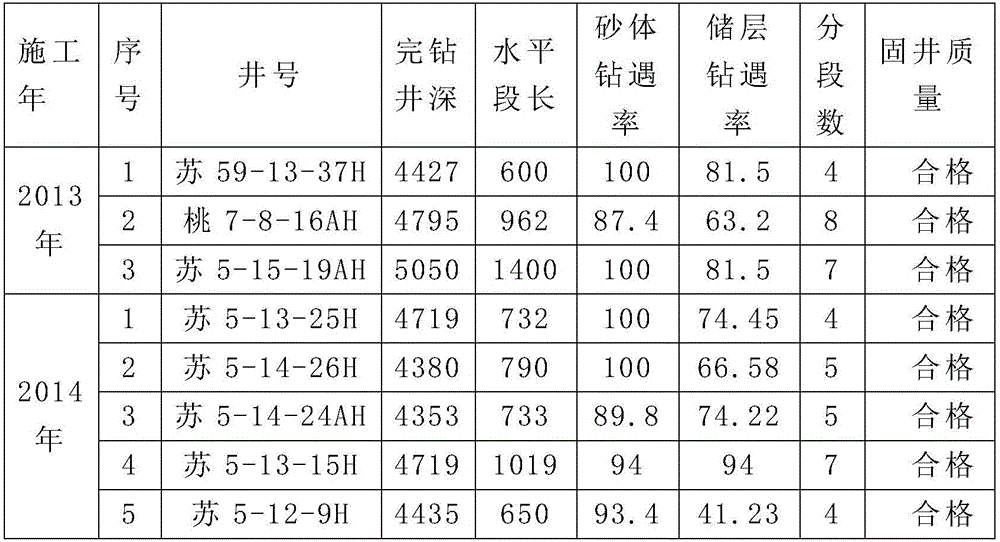

Examples

Embodiment 1

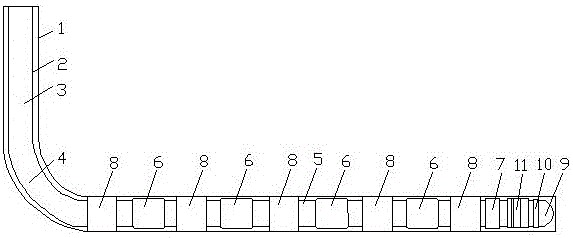

[0040] A cementing and completion construction method for a second open horizontal well, comprising the following steps:

[0041] S1. A drill bit with an outer diameter of 346mm was used for the first drilling, and the well was drilled to a depth of 750 meters, and then an oblong casing with an outer diameter of 273mm was inserted into the well for cementing;

[0042] S2. A drill bit with an outer diameter of 222mm was used for the second straight well section, and the well was drilled to a depth of 2,850 meters. A drill bit with an outer diameter of 215.9mm was used for the second open well section and the horizontal section until the entire well was drilled;

[0043] S3. Connect a single milling column and a double milling column to the drilling tool to simulate the second-opening horizontal well cementing and completion integrated pipe string device to run the well, smooth the borehole wall of the drilled hole, and expand the small diameter of the hole;

[0044] S4. After t...

Embodiment 2

[0053] A cementing and completion construction method for a second open horizontal well, comprising the following steps:

[0054] S1. A drill bit with an outer diameter of 346mm was used for the first drilling, and the well was drilled to a depth of 750 meters, and then an oblong casing with an outer diameter of 273mm was inserted into the well for cementing;

[0055] S2. A drill bit with an outer diameter of 222mm was used for the second straight well section, and the well was drilled to a depth of 2,850 meters. A drill bit with an outer diameter of 215.9mm was used for the second open well section and the horizontal section until the entire well was drilled;

[0056] S3. Connect a single milling column and a double milling column to the drilling tool to simulate the second-opening horizontal well cementing and completion integrated pipe string device to run the well, smooth the borehole wall of the drilled hole, and expand the small diameter of the hole;

[0057] S4. After t...

Embodiment 3

[0071] A cementing and completion construction method for a second open horizontal well, comprising the following steps:

[0072] S1. A drill bit with an outer diameter of 346mm was used for the first drilling, and the well was drilled to a depth of 750 meters, and then an oblong casing with an outer diameter of 273mm was inserted into the well for cementing;

[0073] S2. A drill bit with an outer diameter of 222mm was used for the second straight well section, and the well was drilled to a depth of 2,850 meters. A drill bit with an outer diameter of 215.9mm was used for the second open well section and the horizontal section until the entire well was drilled;

[0074] S3. Connect a single milling column and a double milling column to the drilling tool to simulate the second-opening horizontal well cementing and completion integrated pipe string device to run the well, smooth the borehole wall of the drilled hole, and expand the small diameter of the hole;

[0075] S4. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com