A Construction Method for Two Horizontal Wells

A construction method and horizontal well technology, applied in drilling equipment and methods, directional drilling, earthwork drilling and production, etc., can solve problems such as high development cost, long reservoir reconstruction period, unfavorable horizontal well economy, efficient development, etc., to achieve Good sealing and guarantee the effect of smooth connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

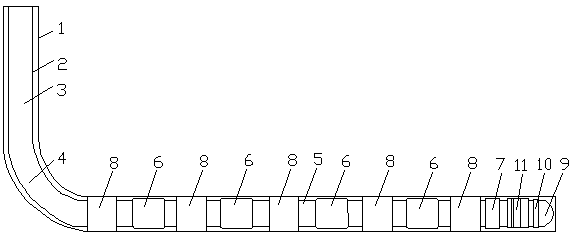

Image

Examples

Embodiment 1

[0050] A method for constructing a second open horizontal well, comprising the following steps:

[0051] S1. A drill bit with an outer diameter of 346mm is used for the first drilling, and the well is drilled to a depth of 700 meters, and then an oblong casing with an outer diameter of 273mm is inserted into the well for cementing;

[0052] S2. A drill bit with an outer diameter of 222mm was used in the second straight well section, and the well was drilled to a depth of 2,800 meters. A drill bit with an outer diameter of 215.9mm was used in the second open well section and the horizontal section until the entire well was drilled;

[0053] S3. Connect a single milling column and a double milling column to the drilling tool to simulate the second-opening horizontal well cementing and completion integrated pipe string device to run the well, smooth the borehole wall of the drilled hole, and expand the small diameter of the hole;

[0054] S4. After the well flow is normal, the dr...

Embodiment 2

[0064] A method for constructing a second open horizontal well, comprising the following steps:

[0065] S1. A drill bit with an outer diameter of 346mm was used for the first drilling, and the well was drilled to a depth of 750 meters, and then an oblong casing with an outer diameter of 273mm was inserted into the well for cementing;

[0066] S2. A drill bit with an outer diameter of 222mm was used for the second straight well section, and the well was drilled to a depth of 2,850 meters. A drill bit with an outer diameter of 215.9mm was used for the second open well section and the horizontal section until the entire well was drilled;

[0067] S3. Connect a single milling column and a double milling column to the drilling tool to simulate the second-opening horizontal well cementing and completion integrated pipe string device to run the well, smooth the borehole wall of the drilled hole, and expand the small diameter of the hole;

[0068] S4. After the well passage is normal...

Embodiment 3

[0087] A method for constructing a second open horizontal well, comprising the following steps:

[0088] S1. A drill bit with an outer diameter of 346mm is used for the first drilling, and the well is drilled to a depth of 800 meters, and then an oblong casing with an outer diameter of 273mm is inserted into the well for cementing;

[0089] S2. A drill bit with an outer diameter of 222mm was used in the second straight well section, and the well was drilled to a depth of 2,900 meters. A drill bit with an outer diameter of 215.9mm was used in the second open well section and the horizontal section until the entire well was drilled;

[0090] S3. Connect a single milling column and a double milling column to the drilling tool to simulate the second-opening horizontal well cementing and completion integrated pipe string device to run the well, smooth the borehole wall of the drilled hole, and expand the small diameter of the hole;

[0091] S4. After the well flow is normal, the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com