Output shaft torque detection system and working method thereof

A detection system and working method technology, applied in the direction of force/torque/power measuring instrument, measuring device, instrument, etc., can solve the problems such as poor accuracy of shaking the dial, low production efficiency, easy fatigue of operators, etc., and achieve rapid response , Improve production efficiency and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

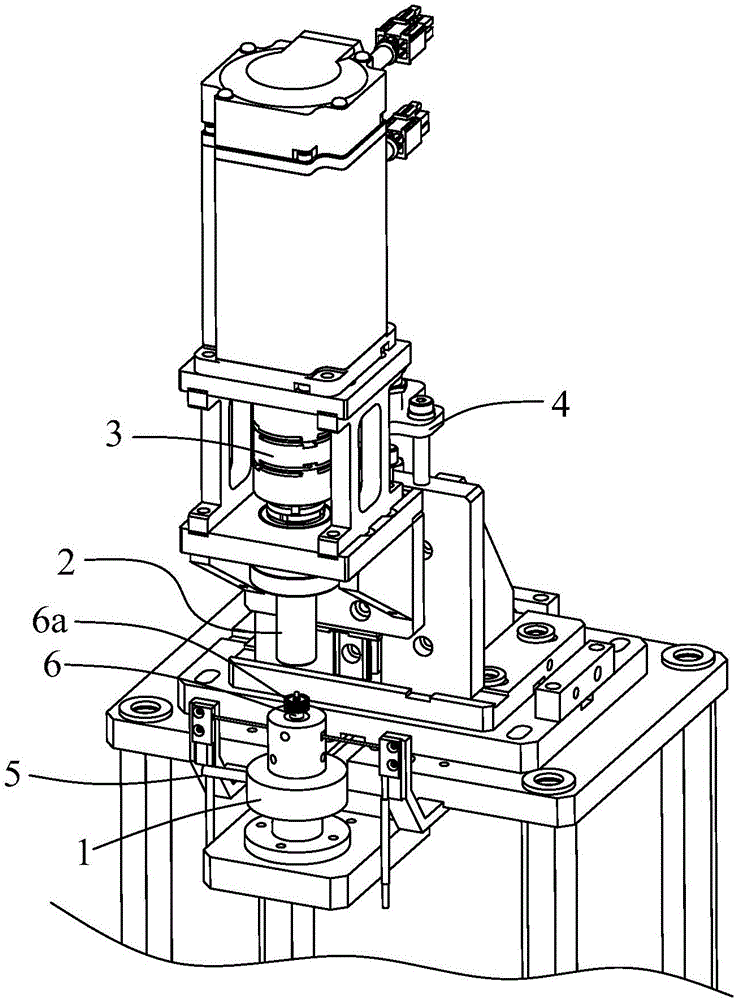

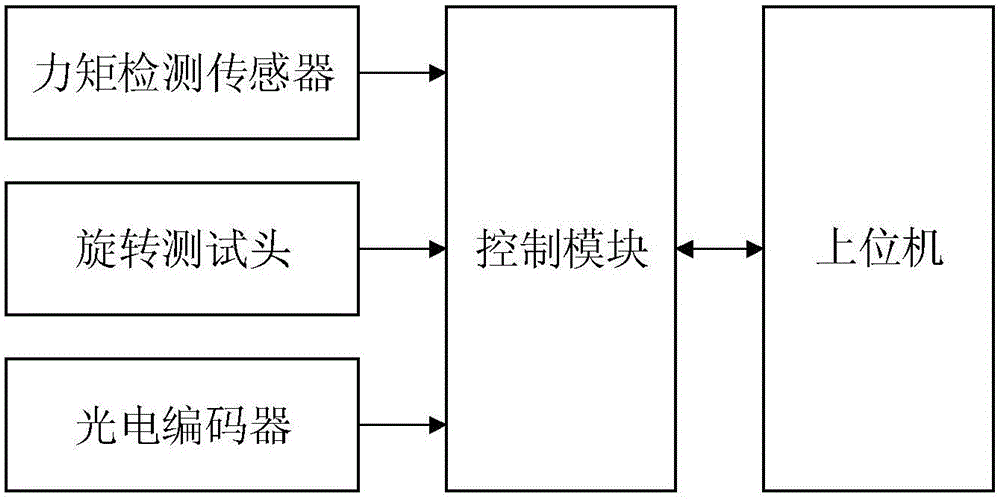

[0038] Such as figure 1 and figure 2 As shown, this embodiment 1 provides an output shaft torque detection system, including: a host computer, a control module, and a detection station for placing shaft components; the control module is suitable for obtaining the detection station The corresponding detection data is sent to the host computer to classify the shaft parts.

[0039] Among them, the control module is, for example but not limited to, Mitsubishi, Siemens PLC modules, and industrial computers with built-in embedded systems. The upper computer is for example but not limited to a PC and an industrial computer.

[0040] A torque detection sensor 1 is provided below the detection station, and a rotary test head 2 is provided above; the control module is suitable for driving the rotary test head down by detecting the lifting cylinder, so as to mesh with the gear end of the shaft component, And control the rotating test head to drive the gear 6a of the shaft part 6 to r...

Embodiment 2

[0049] Such as image 3 and Figure 4 As shown, on the basis of embodiment 1, this embodiment 2 also provides a working method of the output shaft torque detection system, including the following steps:

[0050] Step S1, detection; and

[0051] Step S2, sorting.

[0052] The output shaft torque detection system is as described in Embodiment 1, and will not be repeated here.

[0053] Specifically, the method detected in the step S1 includes:

[0054] Step S11, starting torque detection, and

[0055] Step S12, friction torque detection.

[0056] Set the sorting range values corresponding to the initial torque and friction torque data through the host computer. Specifically, the sorting range value corresponding to the initial torque is for example Figure 4 In the range of 5-5.5, the sorting range value corresponding to the friction torque is for example Figure 4 In the range of 4.5-6.

[0057] The method for detecting the initial torque in step S11 includes: the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com