Device and testing method for testing seepage failure rule under angle variable condition

A variable angle and regular technology, applied in the field of soil penetration failure parameter testing, can solve problems such as further research on piping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

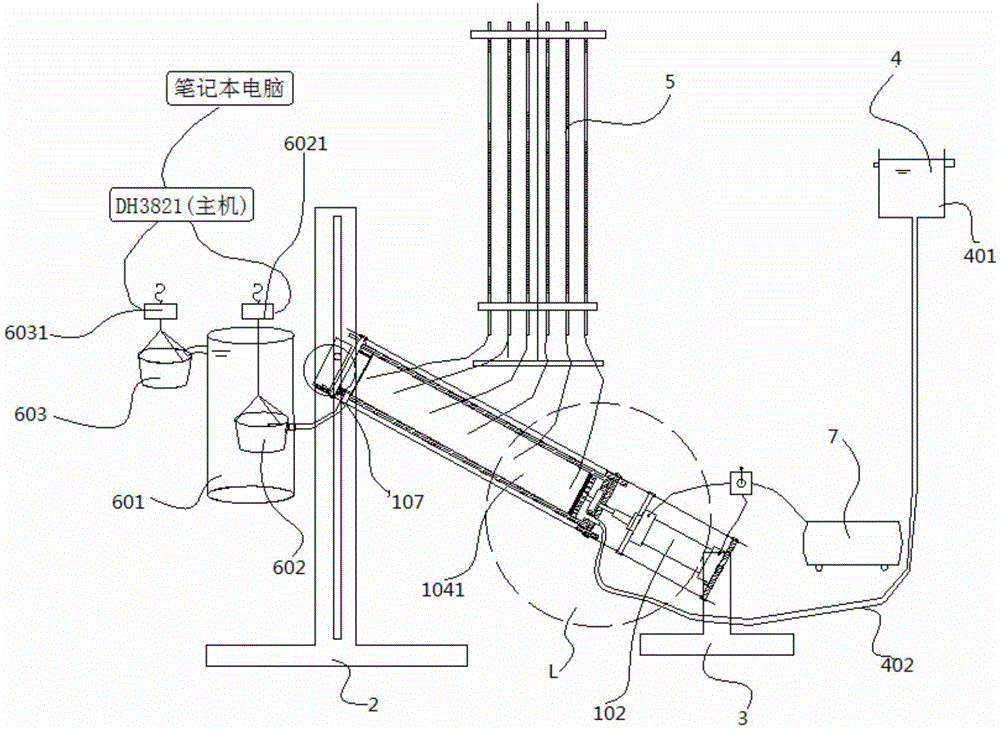

[0066] join figure 2 , this embodiment discloses a device for testing the law of penetration failure under variable angle conditions, including a sample loading system, a front support 2, a rear support 3, an upstream water head application system 4, a pressure measurement system 5 and a solid-liquid separation weighing system.

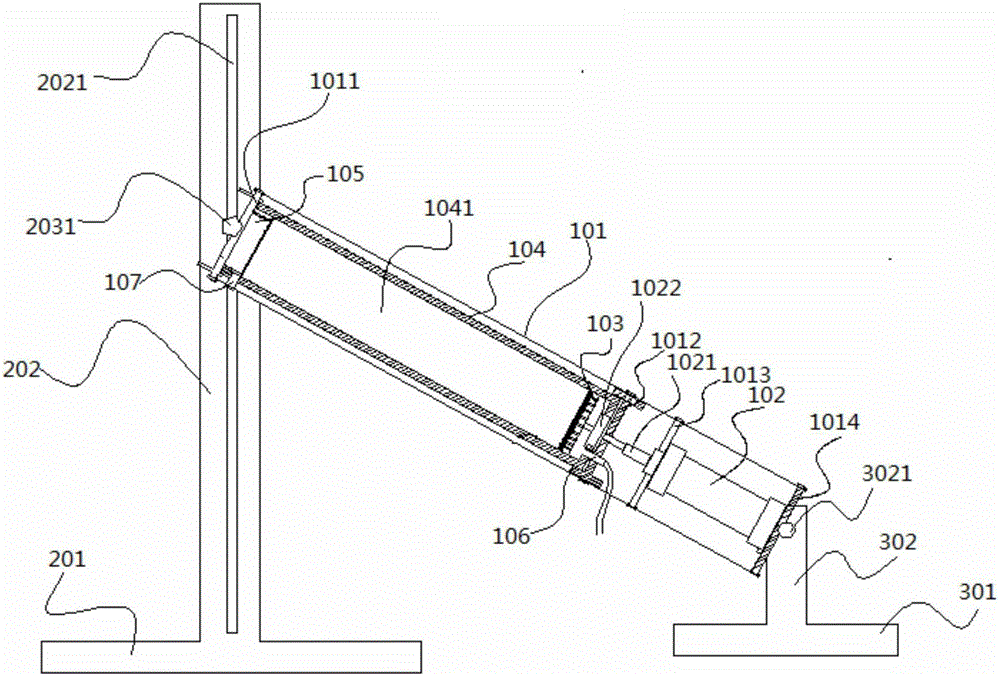

[0067] see image 3 , the sample loading system includes a plexiglass sleeve 101, a top plate 1011, an upper partition 1012, a lower partition 1013, a bottom plate 1014, a cylinder 102, a lower buffer zone B, a sample cylinder 104 and an upper buffer zone A.

[0068] The sample cylinder 104 , the lower buffer zone B, the upper buffer zone A and the cylinder 102 are located inside the plexiglass sleeve 101 . Both ends of the plexiglass sleeve 101 are sealed with a top plate 1011 and a bottom plate 1014 . In the embodiment, bolts are used to connect the machine glass sleeve 101, the top plate 1011 and the bottom plate 1014

[0069] The upper buffer ...

Embodiment 2

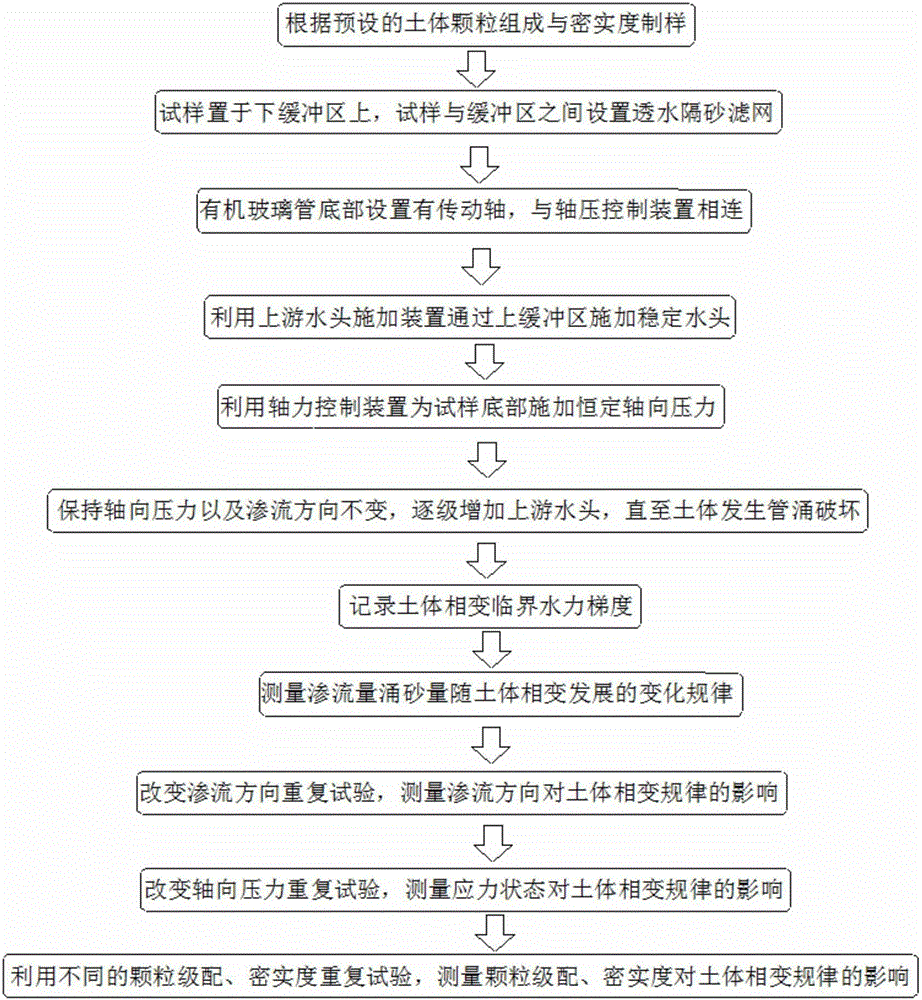

[0088] The present embodiment discloses a method for testing the law of penetration failure under the test variable angle condition using the device described in Embodiment 1, which is characterized in that, comprising the following steps:

[0089] 1) Prepare samples according to the preset soil particle composition and compactness to obtain test samples.

[0090] 2) Put the sample into the sample area. The sample is placed on the lower buffer zone B, and a permeable sand filter is set between the sample and the lower buffer zone B.

[0091] 3) The cylinder is connected with the axial pressure control device (air compressor with control system). According to the seepage direction, adjust the inclination angle of the sample. In this step, according to the preset seepage direction, adjust the tightness of the pin I (2031) to adjust the height of the front end of the sample (S) up and down, and at the same time adjust the distance between the front and rear supports, and then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com