Pseudo soldering examining and judging method for BGA and CSP type chip spherical welding spots

A spherical and chip technology, applied in the direction of measuring devices, instruments, measuring electronics, etc., can solve the problems that the center of the upper and lower pads of the solder joints cannot be completely aligned, the design and manufacturing time and cost are high, and the spherical solder joints cannot be accurately distinguished, etc., to achieve Avoid irreversible destructive, high cost, and high judgment accuracy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

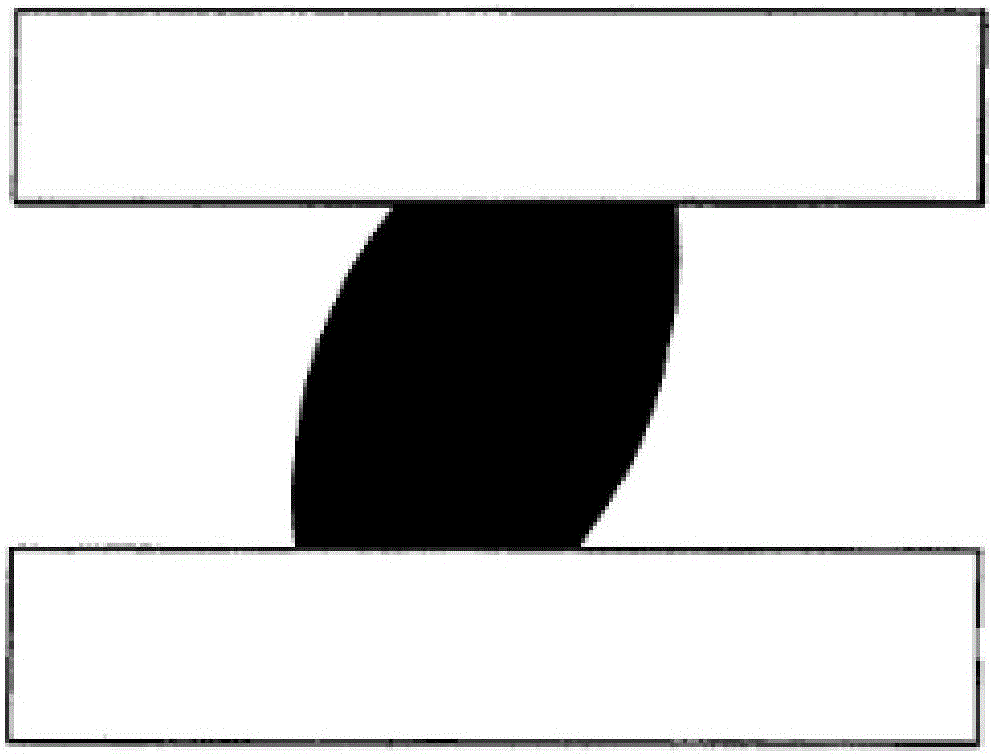

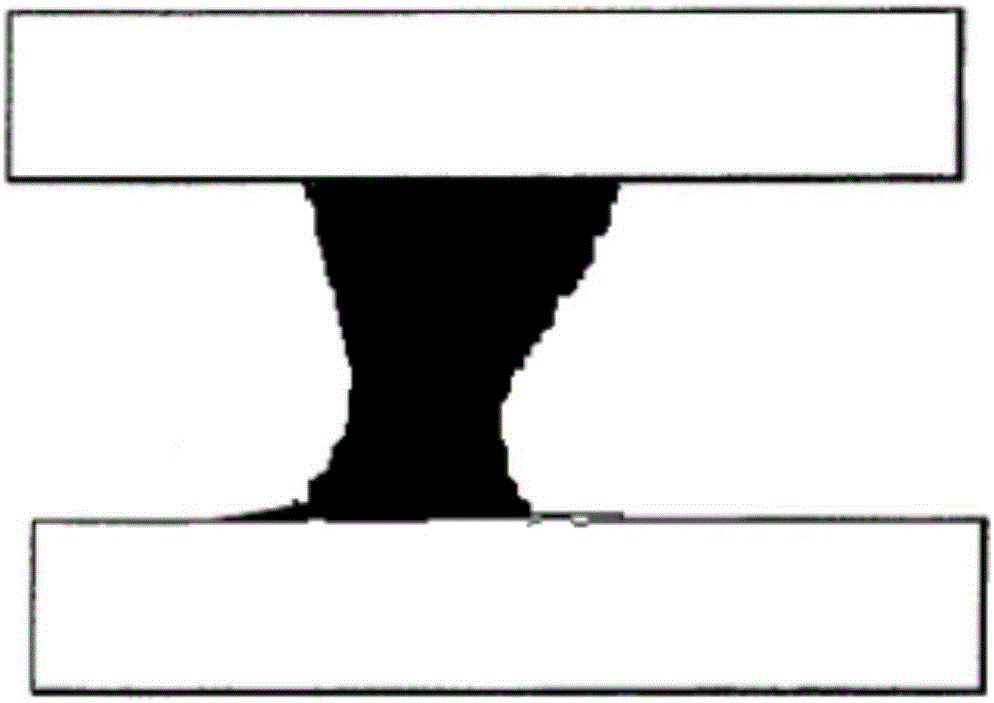

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the embodiments.

[0030] The method for inspecting the virtual solder joints of BGA and CSP chip spherical solder joints comprises the following steps:

[0031] (1) Prepare an X-ray fluoroscopy inspection equipment with oblique irradiation function. Shimadzu SMX-1000PLUS micro-focus X-ray fluoroscopy device can be used. The maximum tube voltage of this equipment is 90KV, the maximum tube current is 110μA, and the resolution is 5μm. The magnification is 7-161 times, and the tilt angle range is between 0-60°;

[0032] (2) Open the equipment door and put the circuit board to be inspected on the equipment stage; open the radiation generating device, and move the part to be inspected under the radiation;

[0033] (3) Set the device parameters as follows: the tube volt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap