Round header shell-and-tube water storage central heating multi-pipe heat-conducting heat exchanger and production technique thereof

一种圆联箱、换热器的技术,应用在圆联箱壳管储水暖气多管导热换热器领域,能够解决热水不能连续流出、结构复杂、热源利用率低等问题,达到方便维护清洗污垢、提高传热面积、传热结构合理的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

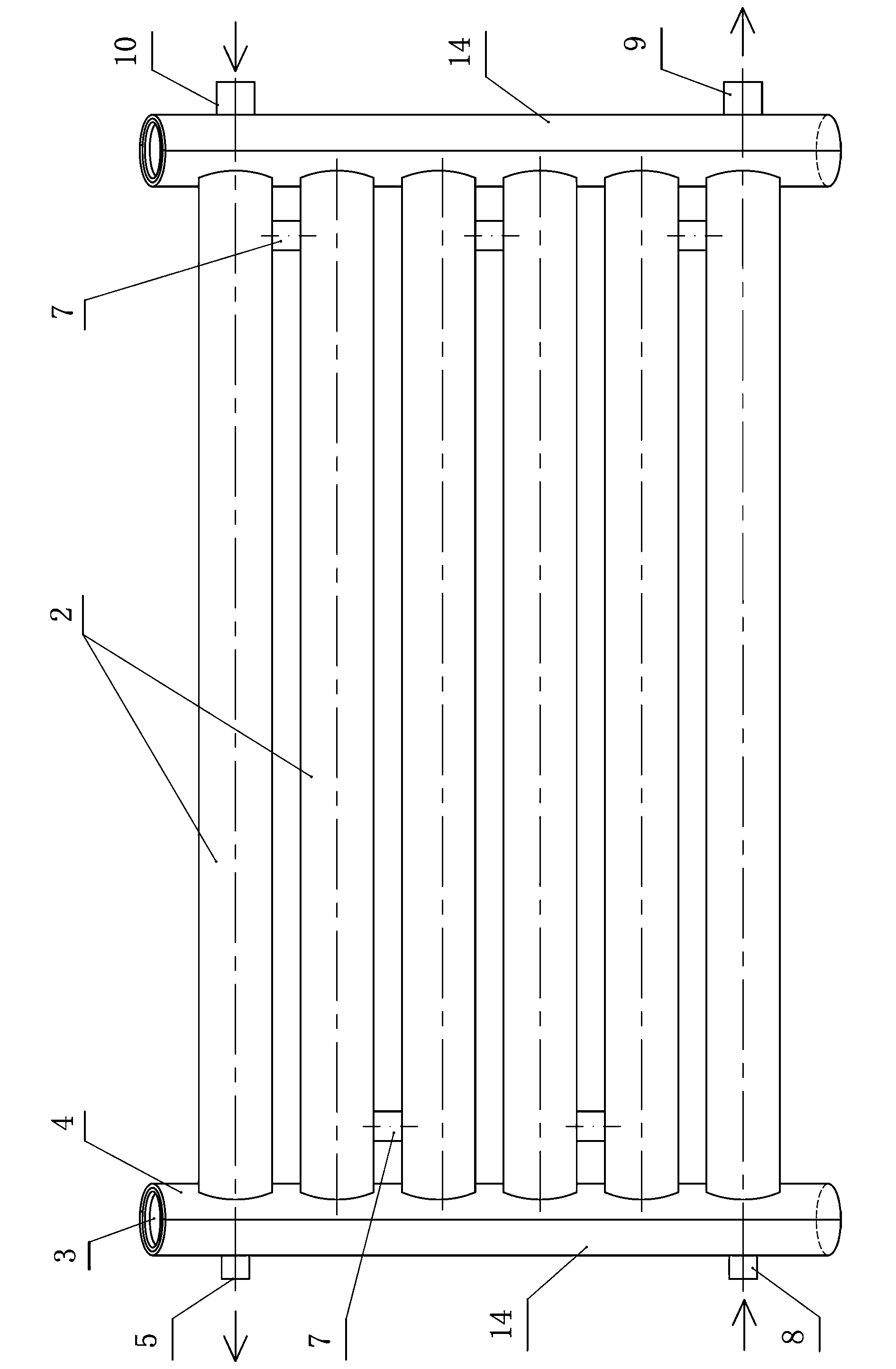

[0037] The round header shell tube water storage heating multi-tube heat conduction heat exchanger of the present invention is as follows Figure 1-20 shown.

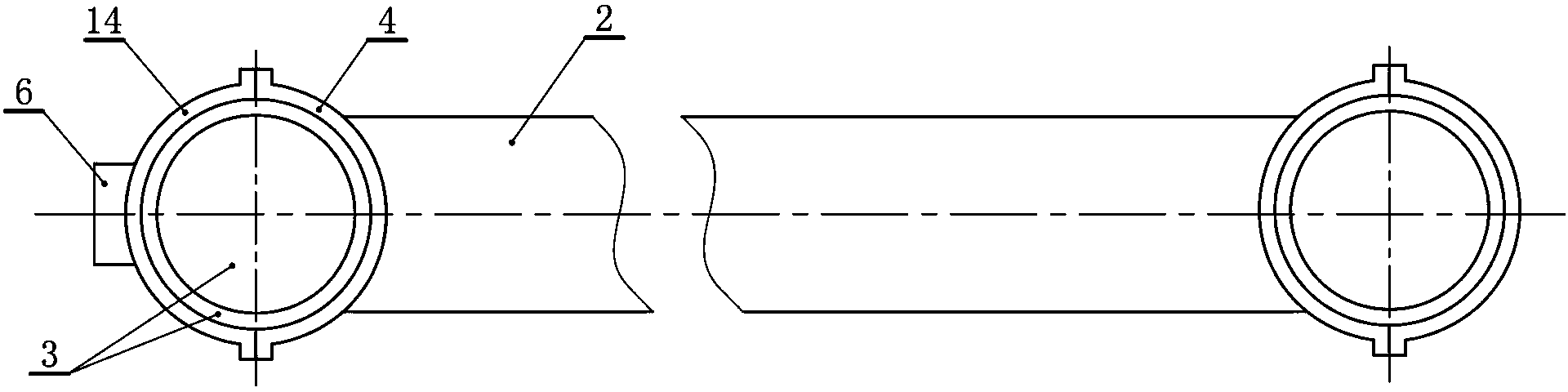

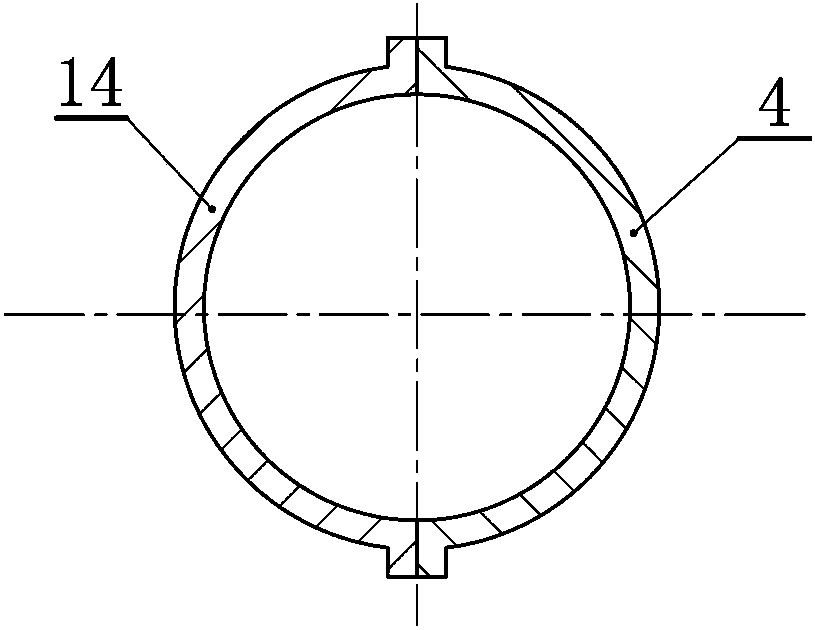

[0038] 1, the present invention as figure 1 , 2 , 4, 5, 6, 11, 12, 13, 17, 10, 20, including the header body, the header body includes the outer circular arc plate 14 of the header, the inner circular arc orifice plate 4 of the header and the end cover Plate 3; the outer circular arc plate 14 of the header is airtightly connected with the inner circular arc orifice plate 4 of the header, and the end cover plates 3 are respectively airtightly connected to both ends of the header body; the outer circular arc plate 14 of the header, the inner circular arc of the header The space surrounded by the orifice plate 4 and the end cover plate 3 is the inner chamber 12 of the header; multiple cold wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com