Engineering safety monitoring method and engineering safety monitoring instrument

A safety monitoring and engineering technology, applied in program control, instrument, computer control, etc., can solve problems such as inability to install, insufficient positioning accuracy, etc., and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 of the present invention is a methane monitor.

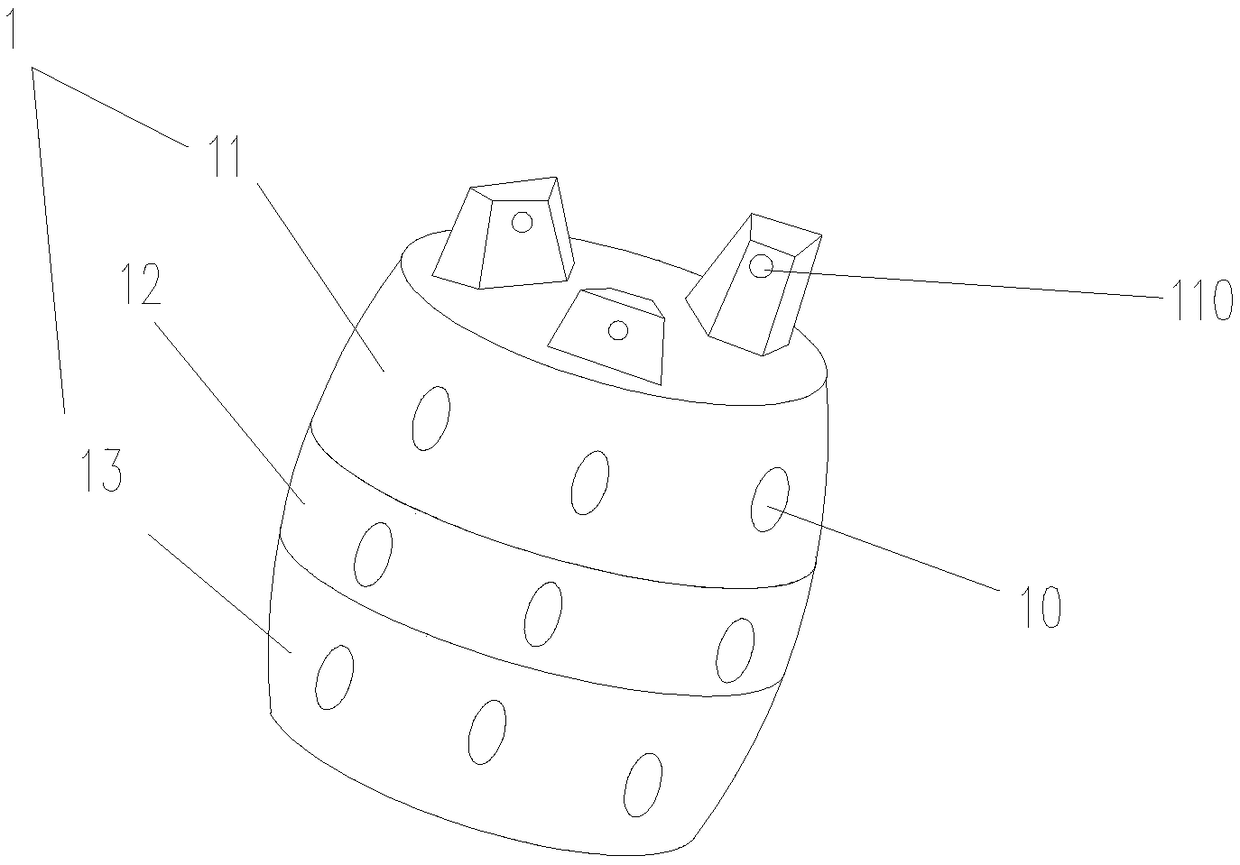

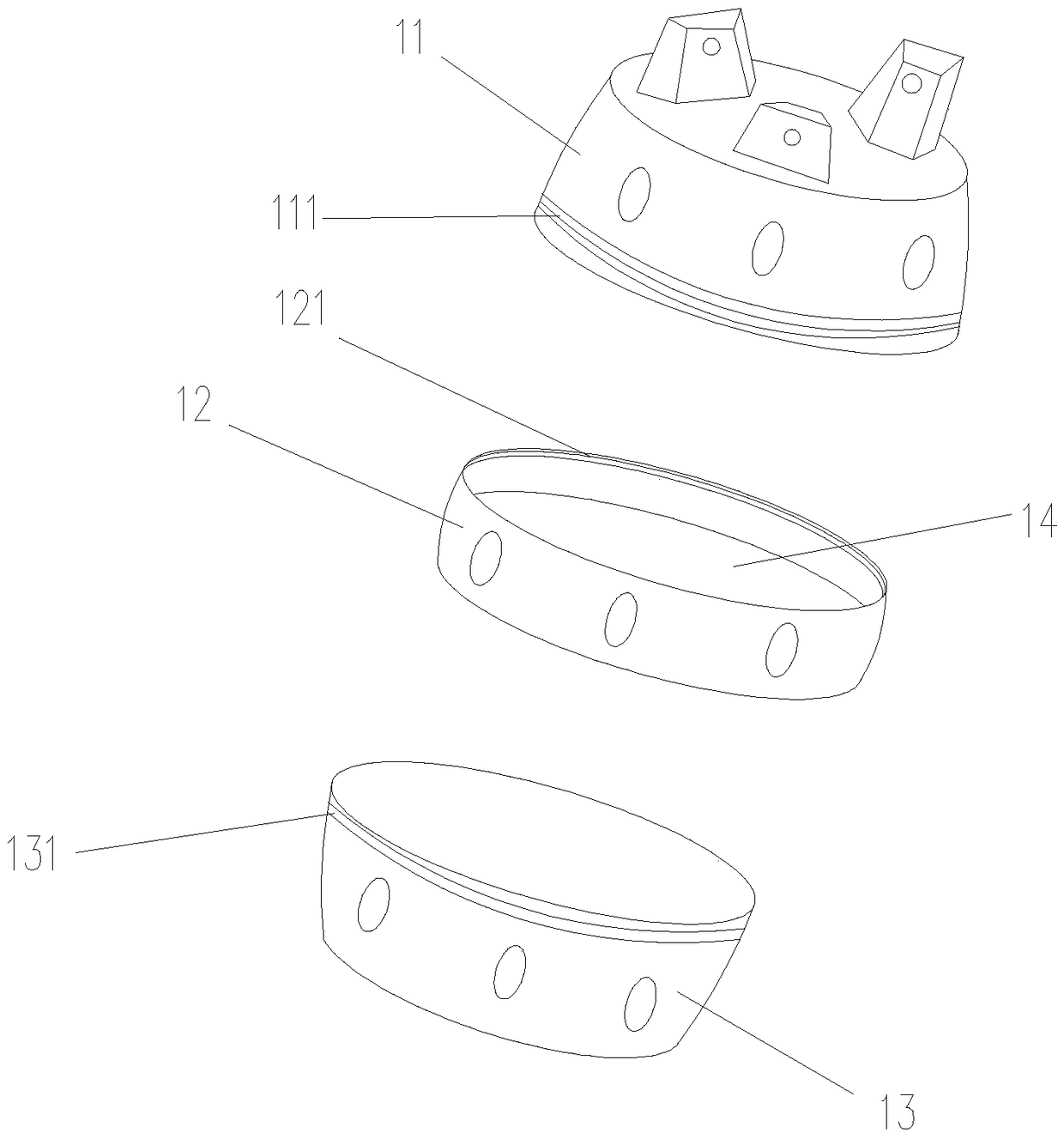

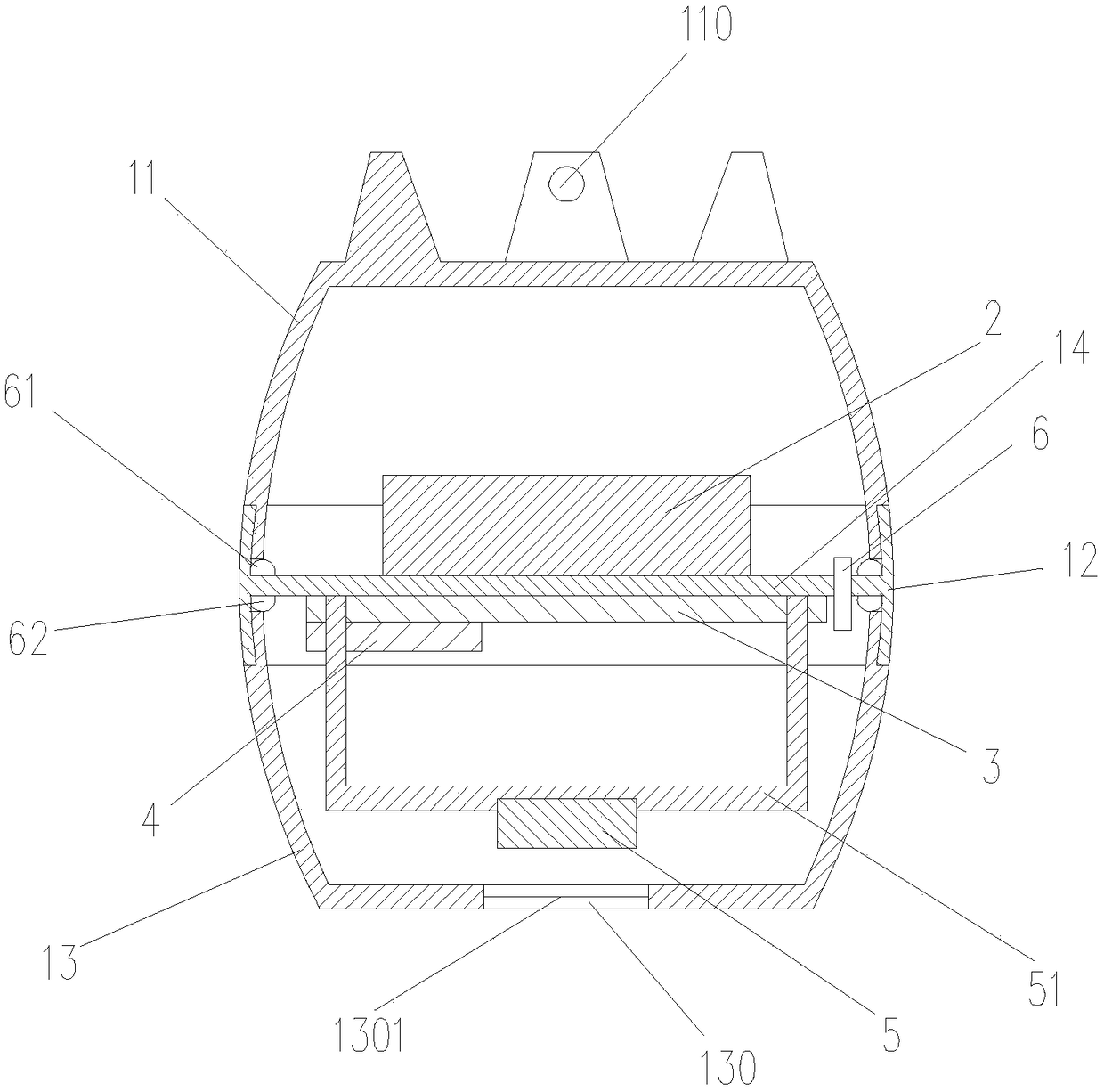

[0053] Such as figure 1 , figure 2 , image 3 As shown, the housing 1 of the present invention includes three parts: an upper cover 11, a middle layer 12, and a lower cover 13, and the upper cover 11, the middle layer 12, and the lower cover 13 are all made of plastic. The outer surface of the housing 1 has a pit 10 for easy gripping.

[0054] The middle layer 12 is a ring-shaped body with a partition 14 in the middle. The battery 2 is fixed on the upper surface of the partition 14 ;

[0055] The lower surface of dividing plate 14 is fixed with sensor support 51 with screw, and methane detection sensor 5 (alkane detection sensor selects MH-440D infrared combustible gas sensor for use) is fixed in the concave hole that the top of sensor support 51 is established.

[0056]The outer thread 111 on the lower part of the upper cover 11 is screwed with the inner thread 121 on the upper part of the middle layer ...

Embodiment 2

[0067] Embodiment 2 of the present invention is an early warning device for ground construction.

[0068] Such as Figure 5 , Image 6 , Figure 7 As shown, the housing 1' of the present invention includes three parts: an upper cover 11', a middle layer 12', and a lower cover 13'. The upper cover 11', the middle layer 12', and the lower cover 13' are all made of plastic. The outer surface of the housing 1' has a recess 10' for easy gripping.

[0069] The middle layer 12' is a ring-shaped body with a separator 14' in the middle. The battery 2' is fixed on the upper surface of the separator 14'; the circuit board 3' is fixed on the lower surface of the separator 14'.

[0070] The outer thread 111' on the lower part of the upper cover 11' is screwed with the inner thread 121' on the upper part of the middle layer 12', and the upper cover 11' abuts against the sealing ring 61' provided on the upper part of the middle layer 12'. The external thread 131' on the upper part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com