A tool positioning method suitable for side milling of non-developable ruled surfaces

A technology of tool positioning and texture, which is applied in general control systems, program control, instruments, etc., can solve the problems of large calculation time, principle error, and large error, and achieve the effect of improving processing efficiency and reducing processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

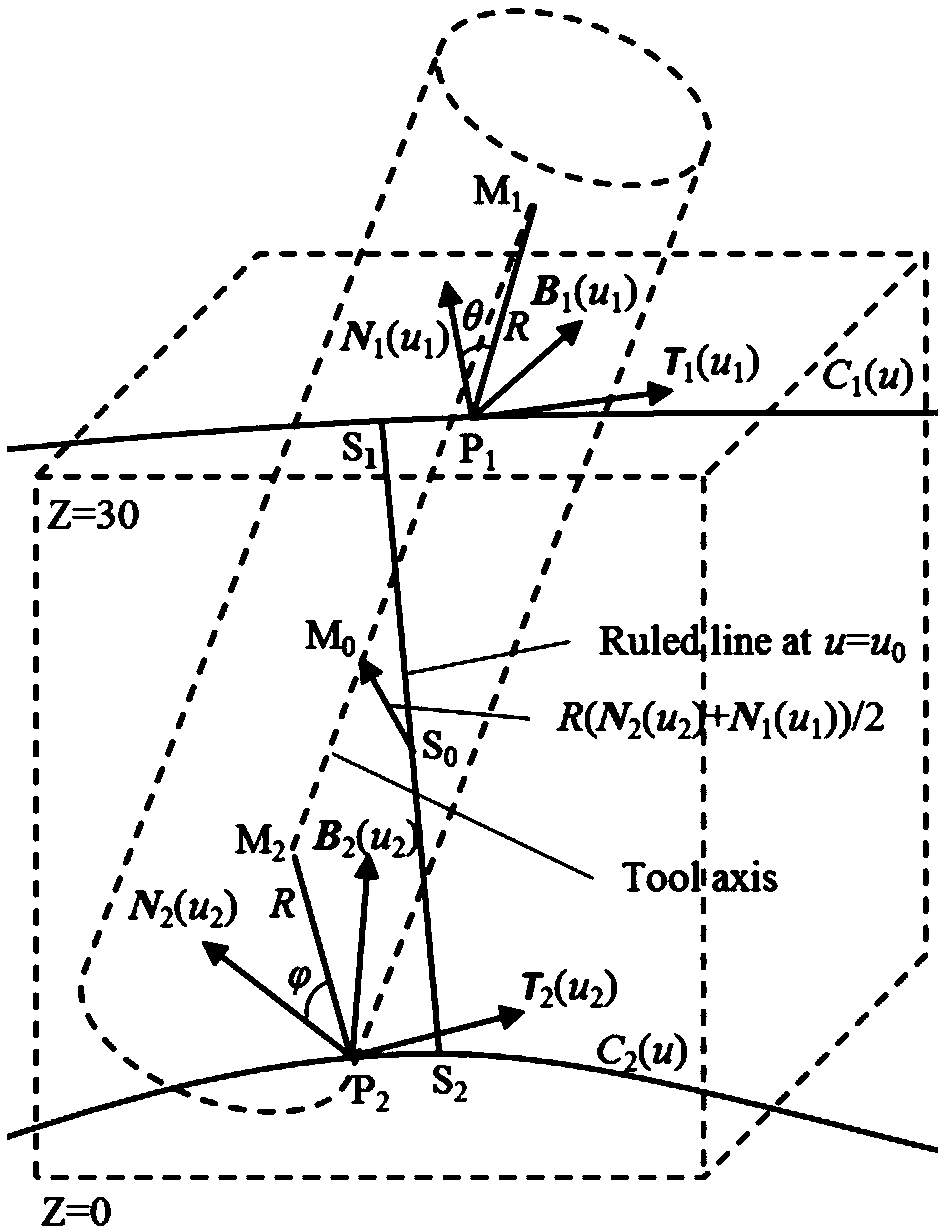

[0029] Such as image 3 As shown, the present invention provides a tool positioning method suitable for side milling non-developable ruled surfaces, which includes the following steps:

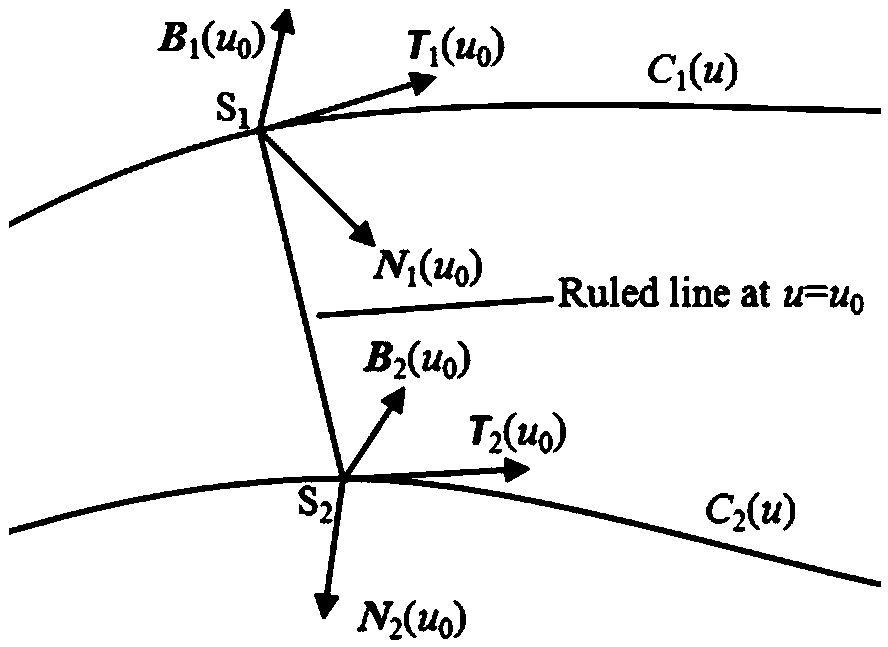

[0030] 1) Select the non-developable ruled surface of the part to be processed, and the upper and lower boundary curves of the non-developable ruled surface are C 1 (u) and C 2 (u).

[0031] 2) Select any straight generatrix S on the non-developable ruled surface 1 S 2 , the straight bus S 1 S 2 The corresponding parameter value is u=u 0 .

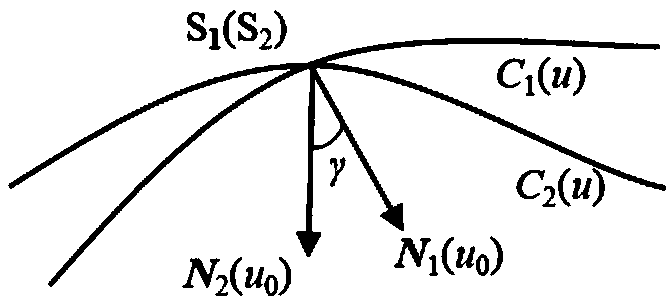

[0032] 3) Straight busbar S in step 2) 1 S 2 Select the unknown parameter u nearby 1 and u 2 , u 1 Corresponding upper boundary curve C 1 Point P on (u) 1 , u 2 Corresponding to the lower boundary curve C 2 Point P on (u) 2 , the upper boundary curve C 1 (u) at P 1 The unit tangent vector of a point is T 1 (u ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com