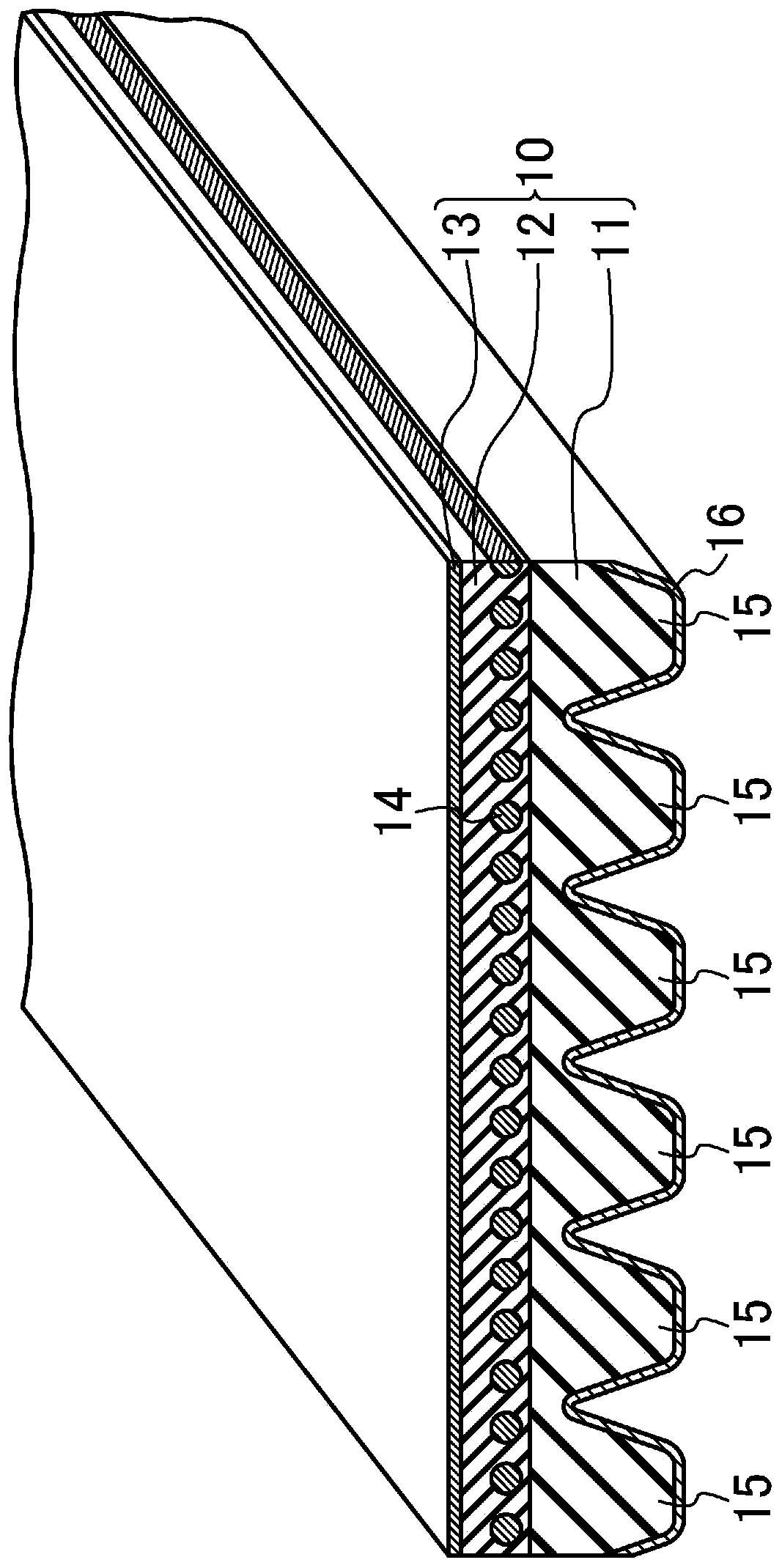

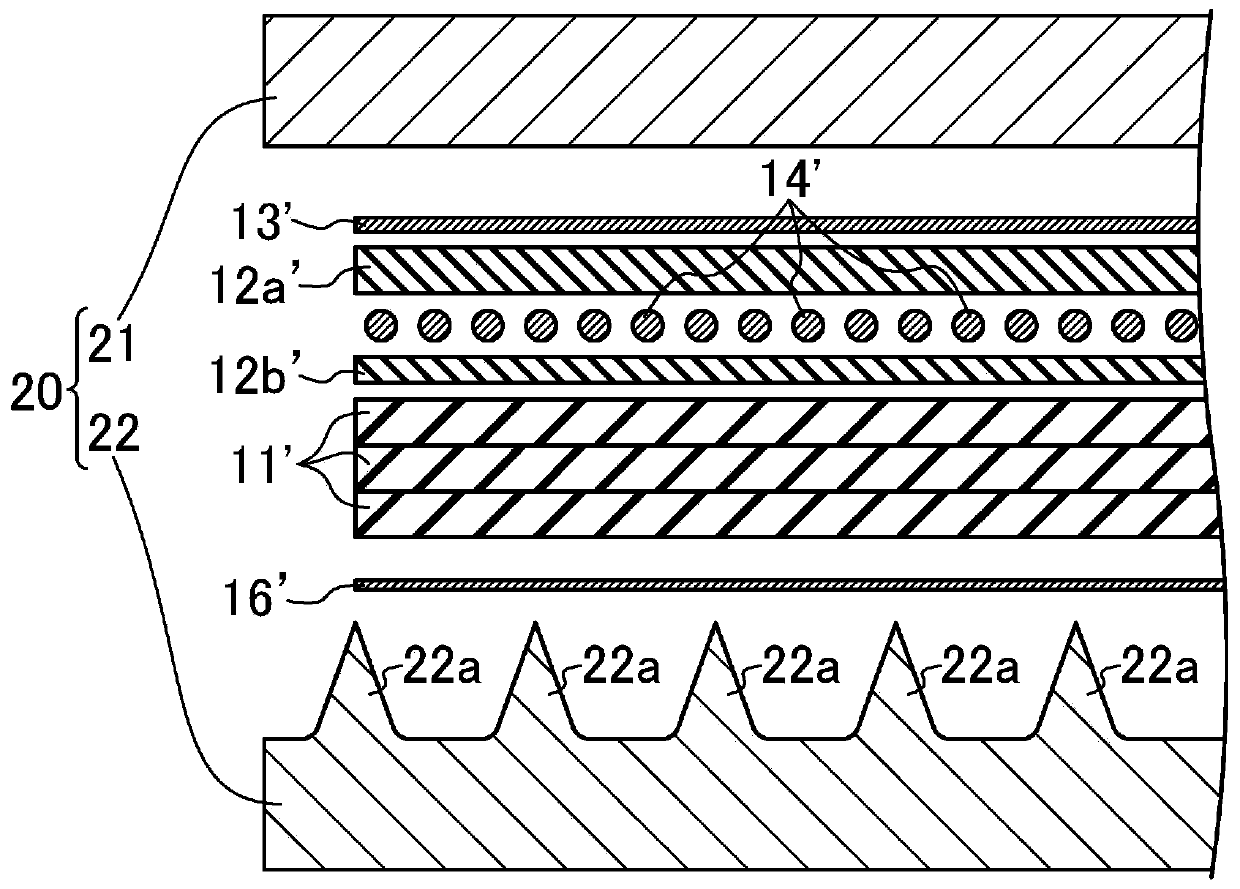

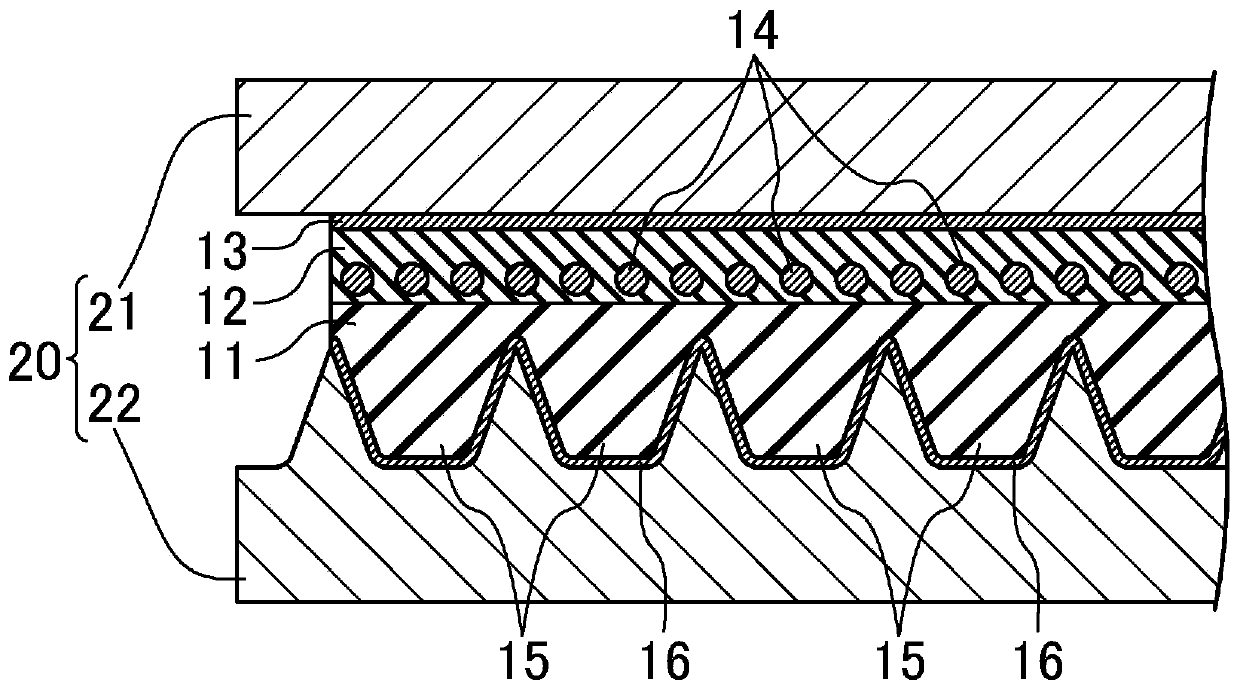

Transmission belt

A technology for rubbing transmission belts and transmitting power, applied in the field of transmission belts, can solve the problems of belt slippage, increased fuel consumption, stick-slip abnormal noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] (rubber composition)

[0060] The rubber composition described below was adjusted for producing a belt. Its composition is also shown in Table 1.

[0061] Using EPDM (manufactured by Mitsui Chemicals, trade name: EPT3045) as the raw rubber, 60 parts by mass of HAF carbon black (manufactured by TOKAI CARBON CO., LTD., trade name: SEAST S0) was added to 100 parts by mass of the raw rubber. Lithium removal (manufactured by H0JUN CO., LTD., trade name: Bengel A, swelling power: 46ml / 2g, cation exchange capacity: 94meg / 100g) 30 parts by mass, zinc oxide (manufactured by SAKAI CHEMICAL INDUSTRY CO., LTD., commercial product Name: Zinc Flower No. 2) 5 parts by mass, anti-aging agent (manufactured by Ouchi Shinko Chemical Co., trade name: NOCRAC MB) 2 parts by mass, palm oil (manufactured by Idemitsu Kosan Co., Ltd., trade name: Diana Process OilPS-90) 10 parts by mass, sulfur (manufactured by Hosoi Chemicals, trade name: 0IL SULFUR) 2.3 parts by mass, vulcanization accelerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com