Air purification structure stable in purification efficiency

A technology for air purification and purification efficiency, applied in the direction of electrode structure, external electrostatic separator, electrostatic separation, etc., can solve the problems of instability and poor dust collection effect, and achieve the effect of improving the collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

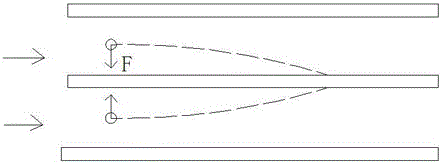

Problems solved by technology

Method used

Image

Examples

Embodiment 1

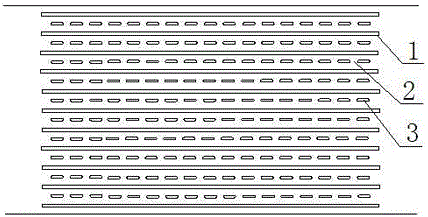

[0015] Such as figure 2 The shown air purification structure with stable purification efficiency includes a plurality of electrode plates 1 arranged in parallel with each other, and a dust collection electrode 3 with holes 2 is arranged between two adjacent electrode plates 1 . When in use, all the electrode plates are electrically connected and connected to the output end of the high-voltage power supply, and all the dust collectors are electrically connected and grounded.

[0016] The diameter of the hole is preferably set at 0.15 mm to 0.25 mm.

Embodiment 2

[0018] The dust collection pole is a metal orifice plate. The metal orifice plate has many holes, which can not only provide a path for changing the dust path, but also collect dust, so that the dust is not easy to be taken away again, so that the dust collection effect is stable.

[0019] The dust collecting pole is arranged parallel to the electrode plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com