A kind of treatment method of two-rotation fly ash

A treatment method and fly ash technology, which is applied in the field of fly ash treatment, can solve the problems such as difficult to realize catalyst recovery in fly ash, low carbon conversion rate of coal catalytic gasification, and difficulty in returning materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A method for treating fly ash provided by an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] An embodiment of the present invention provides a treatment method for two-rotation fly ash, comprising:

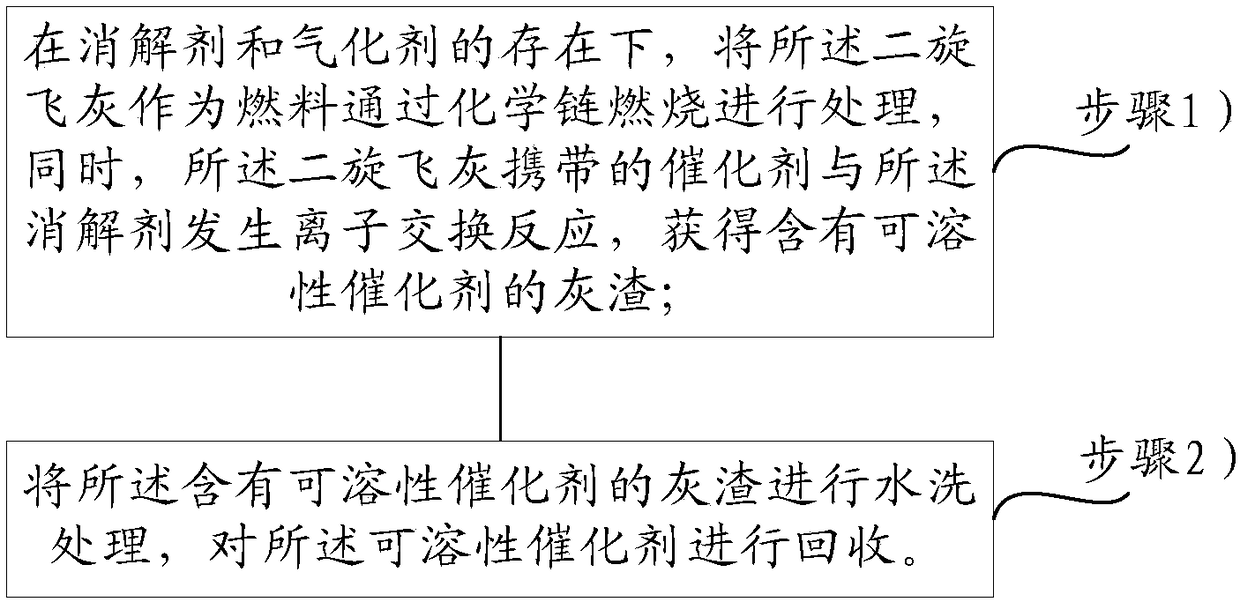

[0024] Step 1) In the presence of a decomposer and a gasification agent, the two-stage fly ash is used as a fuel to be processed through chemical looping combustion, and at the same time, the catalyst carried by the two-stage fly ash undergoes an ion exchange reaction with the digestion agent, Obtaining ash containing soluble catalyst;

[0025] Step 2) washing the ash containing the soluble catalyst with water, and recovering the soluble catalyst.

[0026] The basic principle of chemical loop combustion is to decompose the traditional combustion of direct contact reaction between fuel and air into two gas-solid reactions with the help of oxygen carrier. The oxygen in the air is transferred to the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com