Prediction method of pickling time considering pulling-correcting and scale breaking effect

A technology of pickling time and scale breaking, applied in the field of metallurgy, can solve the problem of neglecting the factors affecting the tension leveler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

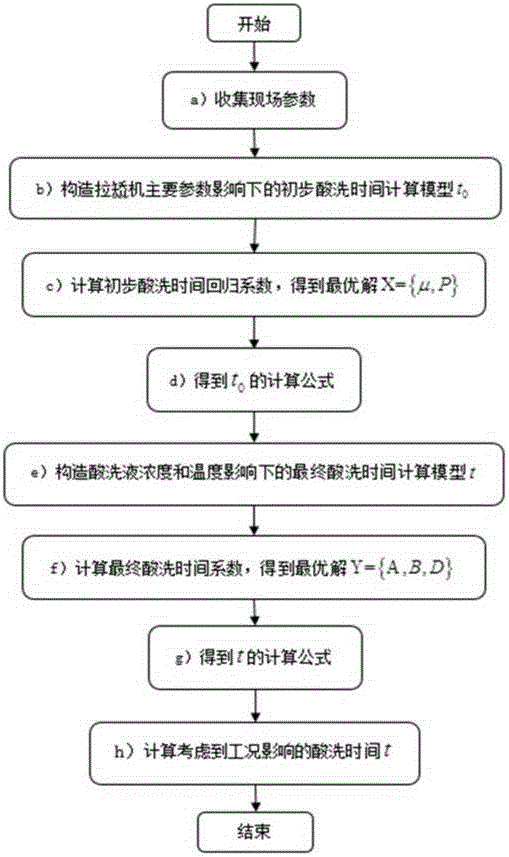

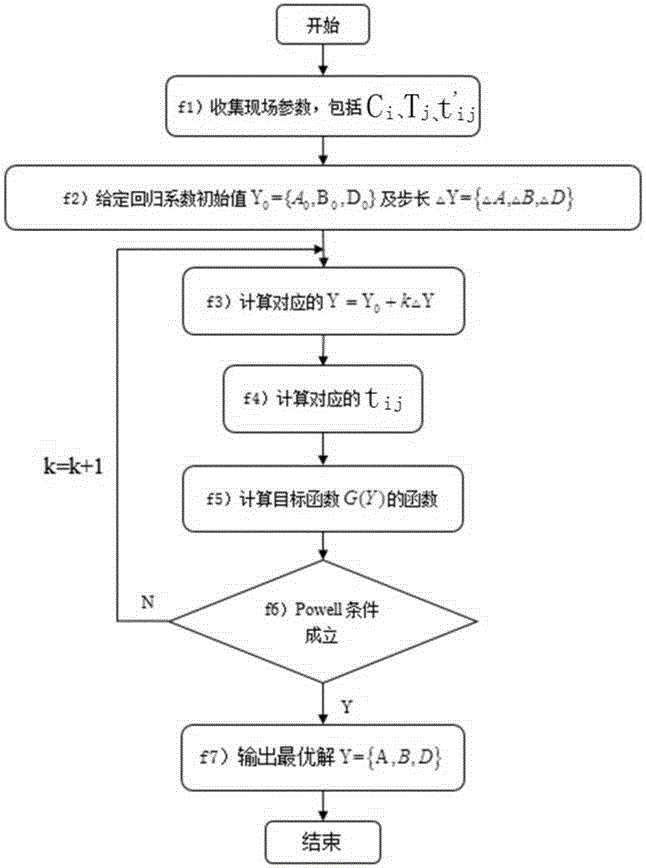

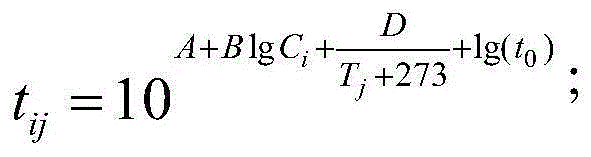

Method used

Image

Examples

Embodiment

[0076] Step a, collect test parameters: the average reduction x of the tension leveler 0 =12. Pickling time t for scale breaking without tension leveling machine 0 = 80s;

[0077] Step b, constructing the calculation model of the influence coefficient of stretching, straightening and scale breaking on pickling time:

[0078] t p = t 0 ( 1 - u F ) 1 + ( x x 0 ) P + u F t 0 , In the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com