Seal height adjusting and locking device of press machine

A technology of closed height and locking device, applied in the field of presses, can solve the problems such as the change of the closed height of the slider and the loosening of the adjusting screw, so as to ensure the stability and improve the processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The closing height adjustment and locking device of the press provided by the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

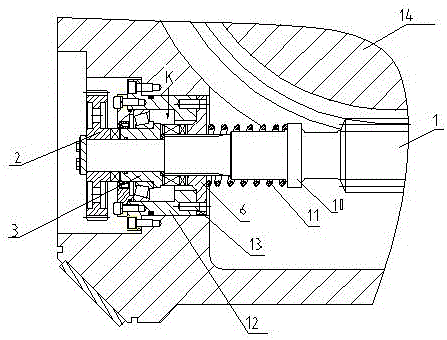

[0017] as attached figure 1 As shown, the closed height adjustment locking device of the press includes the large gear 2 driven by the adjustment motor on the worm shaft 1 and the sleeve 3 on the worm shaft and the teeth of the large gear (the adjustment motor is not shown in the drawings). ).

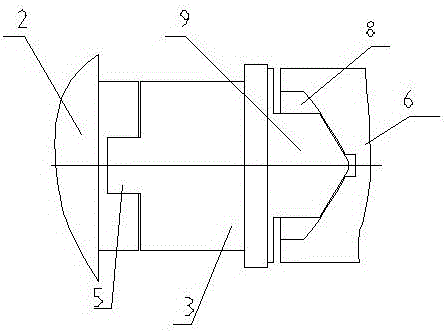

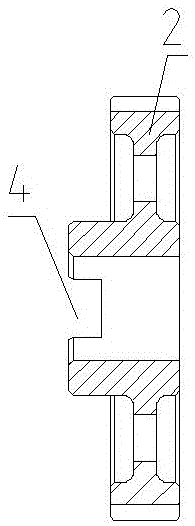

[0018] as attached image 3 As shown, grooves 4 are milled on the end face of the large gear and the bushing, as attached Image 6 As shown, there are teeth 5 on the end surface where the shaft sleeve 3 fits with the bull gear, combined with the attached figure 2 As shown, the teeth 5 are located inside the groove 4 to realize the synchronous free rotation of the large gear 2 and the sleeve 3 on the worm shaft 1 .

[0019] as attached figure 1 As shown, it also includes a brake dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com