Traction/impact device

A buffer device and tension technology, applied in the direction of buffer, traction device, transportation and packaging, etc., can solve the problems of complexity, long structure of tension/impact buffer device, loud noise, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

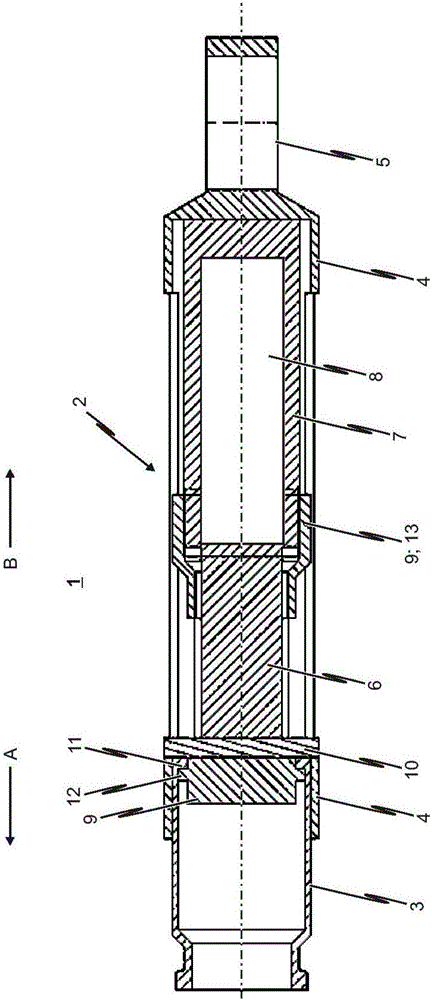

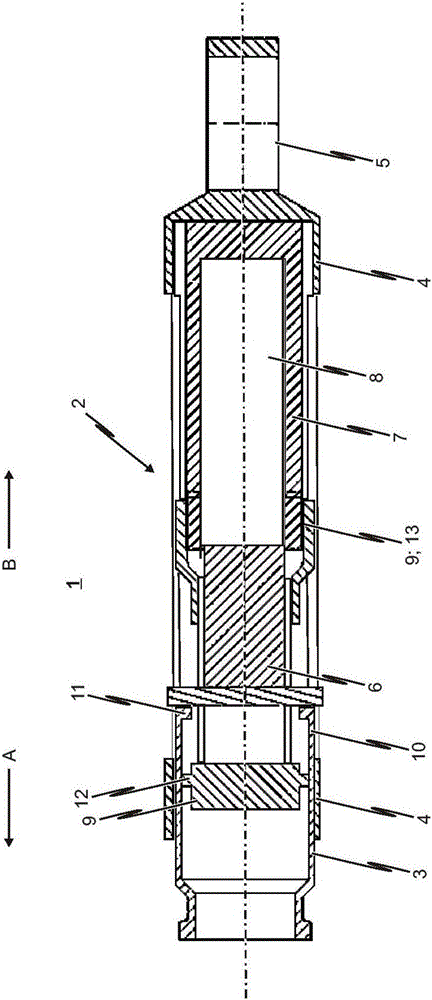

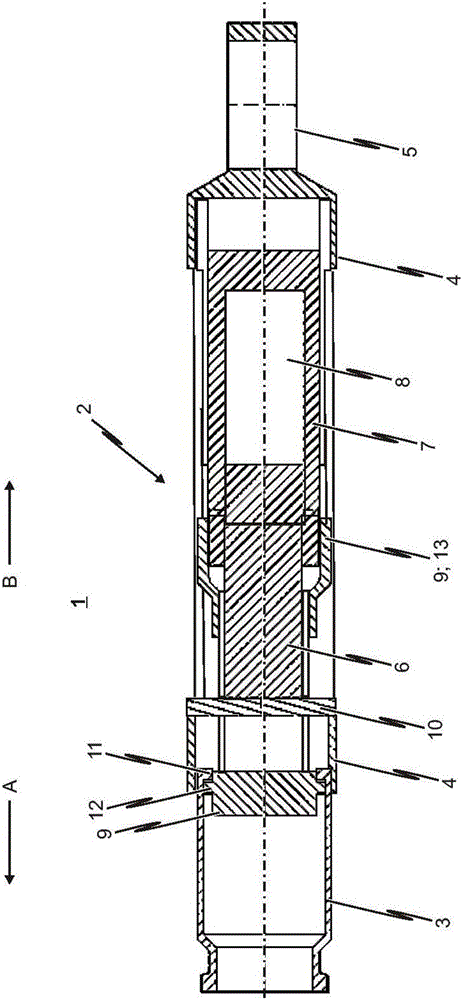

[0052] The structure of the damping mechanism 2 , which in this exemplary embodiment of the tension / impact damping device according to the invention is accommodated and formed at least partially in the damper housing 4 and which damps all The movement of the force transmission element 3 relative to the damper housing 4 when transmitting tension / compression is described.

[0053] Specifically, as only schematically shown in the figures, for this purpose, the damping mechanism has a spring system, which is particularly configured so that both the tensile force and the impact force are transmitted by pneumatic and / or hydraulic means. Can realize the function of cushioning and shock absorption.

[0054] For example, it is conceivable that the spring system of the damping mechanism 2 has a piston rod arrangement with a piston 6 and a cylinder arrangement 7, the piston 6 of the piston rod arrangement being movable relative to the cylinder arrangement 7, so that in this way The pist...

no. 2 approach

[0068] with in figure 1 The same as the first embodiment shown in, for example in Figure 6 The exemplary second embodiment of the tension / impact damping device 1 according to the invention shown in also basically has the following components:

[0069] - a damper housing 4 which is connected or connectable to the body of the vehicle;

[0070] - a force transmission element 3 for transmitting tension or pressure to the damper housing 4 when required, said force transmission element 3 being movable relative to the damper housing 4 both in the direction of tension A and in the direction of impact B; as well as

[0071] Damping means 2 , which are accommodated and formed at least partially in the damper housing 4 and dampen the movement of the force transmission element relative to the damper housing 4 during the transmission of tensile / impact forces.

[0072] The damping mechanism 2 of the tension / impact damping device 1 according to the invention is designed in particular suc...

no. 1 approach

[0076] The invention is not limited to the exemplary embodiment shown in the figures of the tension / impact damping device 1 according to the invention, but rather results generally from the features disclosed therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com