A natural nano mineral stone powder functional fiber and a functional heat energy cotton

A technology of nano-mineral stone powder and functional fiber, which is applied in the direction of fiber chemical characteristics, single-component polyester artificial filament, single-component polyamide artificial filament, etc., can solve problems such as unfavorable human health, achieve good application prospects, Good warmth retention effect, high softness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

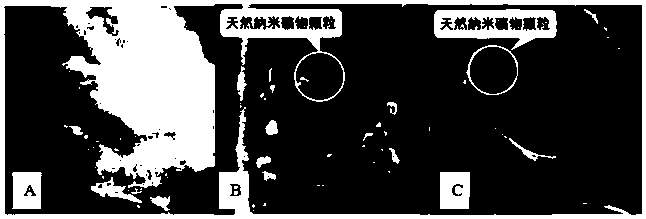

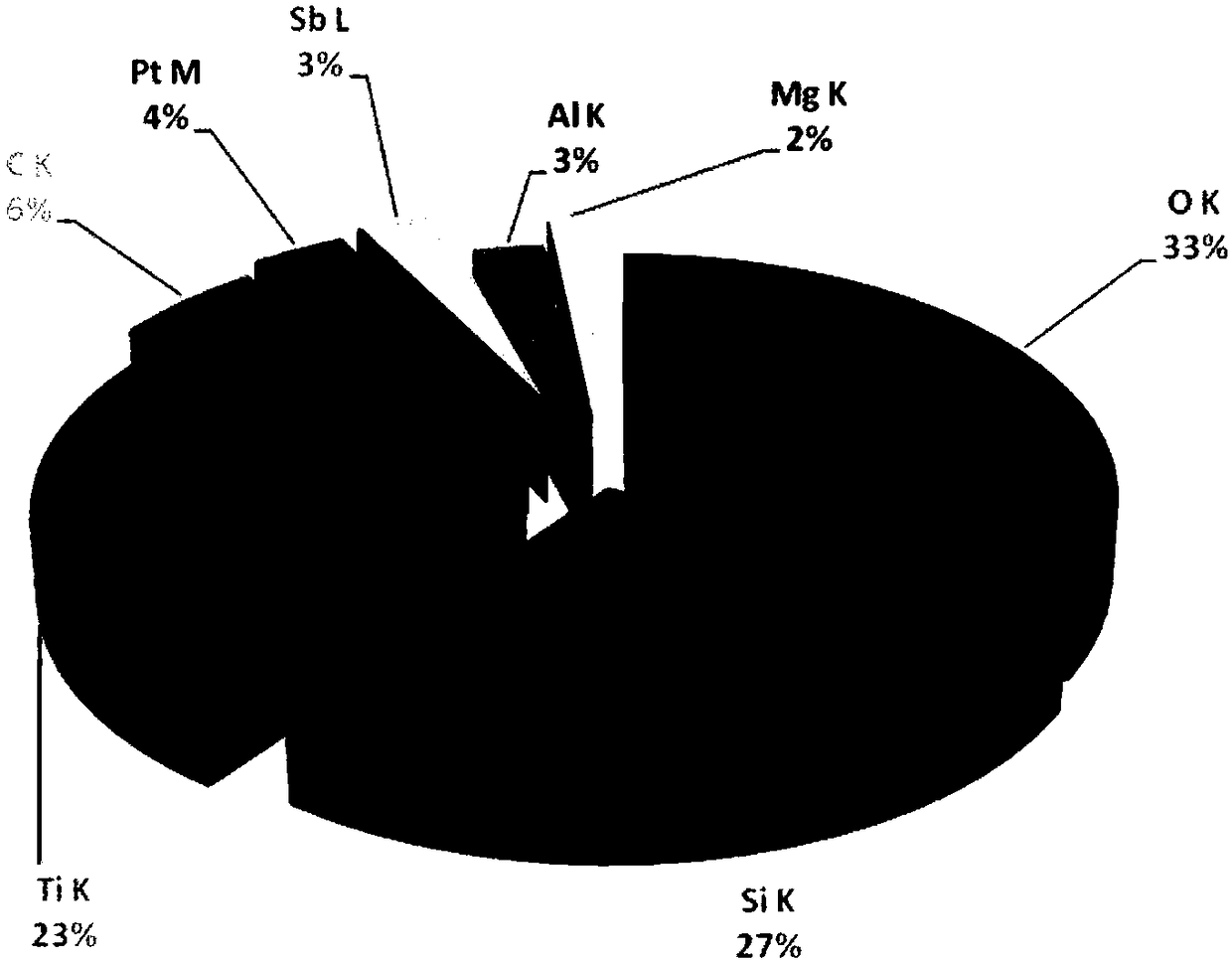

[0049] Collect different natural mineral stones, and use nano high-tech technology to grind 20 kinds of natural minerals to an average particle size of 50-60nm; use nanotechnology to remove defective products from mineral stones, and then follow the figure 1 The ratio shown is ground into natural nano-mineral functional powder, such as figure 2 shown.

[0050] Add nano-mineral powder to synthetic polyester fiber with small molecular raw materials, and copolymerize according to conventional methods to form nano-mineral fiber particles, such as image 3 shown.

[0051] Finally, polyester functional fibers are prepared according to conventional methods. According to different needs, it is prepared into polyester long fibers (such as Figure 4 Shown, also known as "natural nano mineral stone Polyester functional fiber" or "Nanomineral Polyester titanium hollow fiber") or short fiber (as shown in 5, also known as "natural nano mineral stone Polyester functional fiber", is hollo...

Embodiment 2

[0056] Prepare Nylon functional fiber long fiber (also known as "natural nano mineral stone Nylon functional fiber" or "Nanomineral Nylon nano silk wool") according to the same method as Example 1, the content of its nano mineral stone powder is 4wt%. Observing its cross-section and surface, the results are as follows Figure 6 As shown, the cross-section of the long-fiber yarn in this embodiment is an irregular pentagonal shape. From the enlarged view of its surface and cross-section, it can be seen that it contains mineral particles, which are evenly distributed inside and outside the yarn. After repeated washing, the function will not disappear. In addition, the irregular pentagonal shape has good resilience and soft touch, which can increase the comfort and softness of the material.

Embodiment 3

[0058] Woody functional fiber long fibers were prepared according to the same method as in Example 1, and the content of the nano mineral stone powder was 4wt%. Observing its cross-section and surface, the results are as follows Figure 7 As shown, the long-fiber yarn in this example contains mineral particles, which are evenly distributed inside and outside the yarn, and the textiles made of it will not lose their function even after repeated washing. In addition, its cross-section is an irregular structure, so that more surface space is reserved when the fibers are fastened. The skin-friendly comfort is improved, and the air permeability and water absorption are also 2.5 times higher than that of ordinary natural cotton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com