Walking control pedal assembly

A walking control and foot pedal technology, which is used in fluid pressure actuation devices, earth movers/shovels, servo motor assemblies, etc., can solve problems such as inconvenience for drivers and operators, inconvenience in operation, and one-step improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

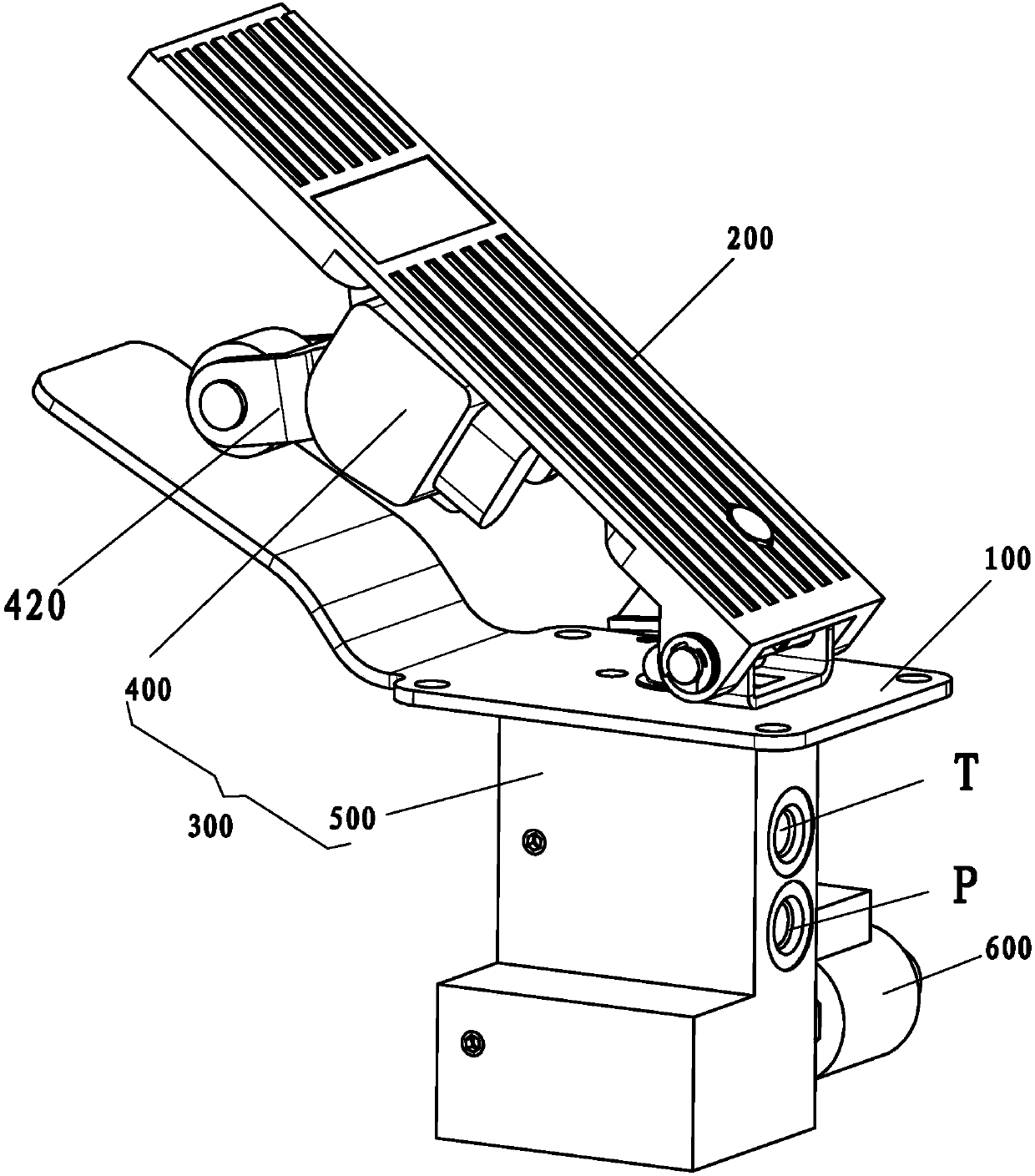

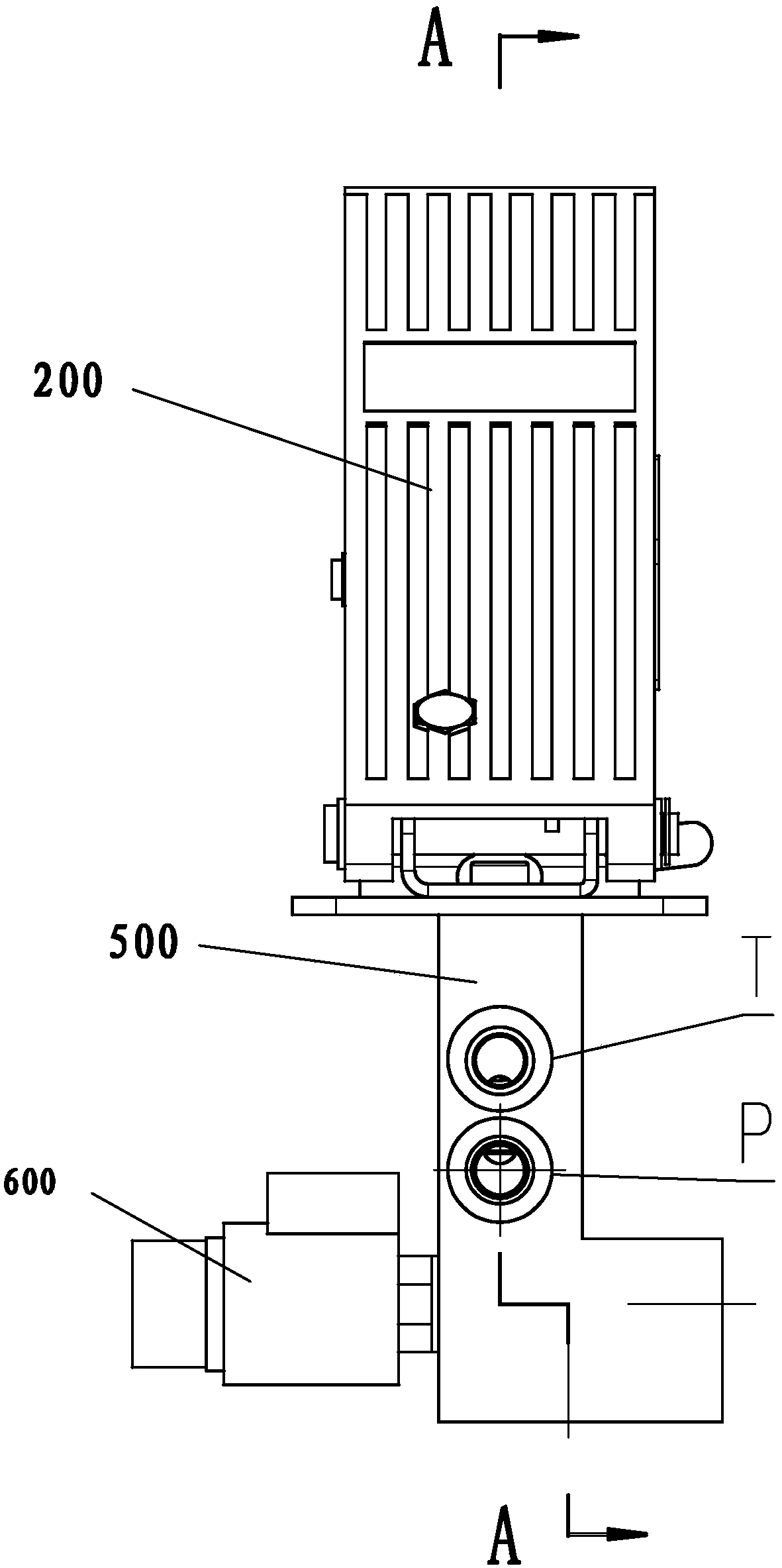

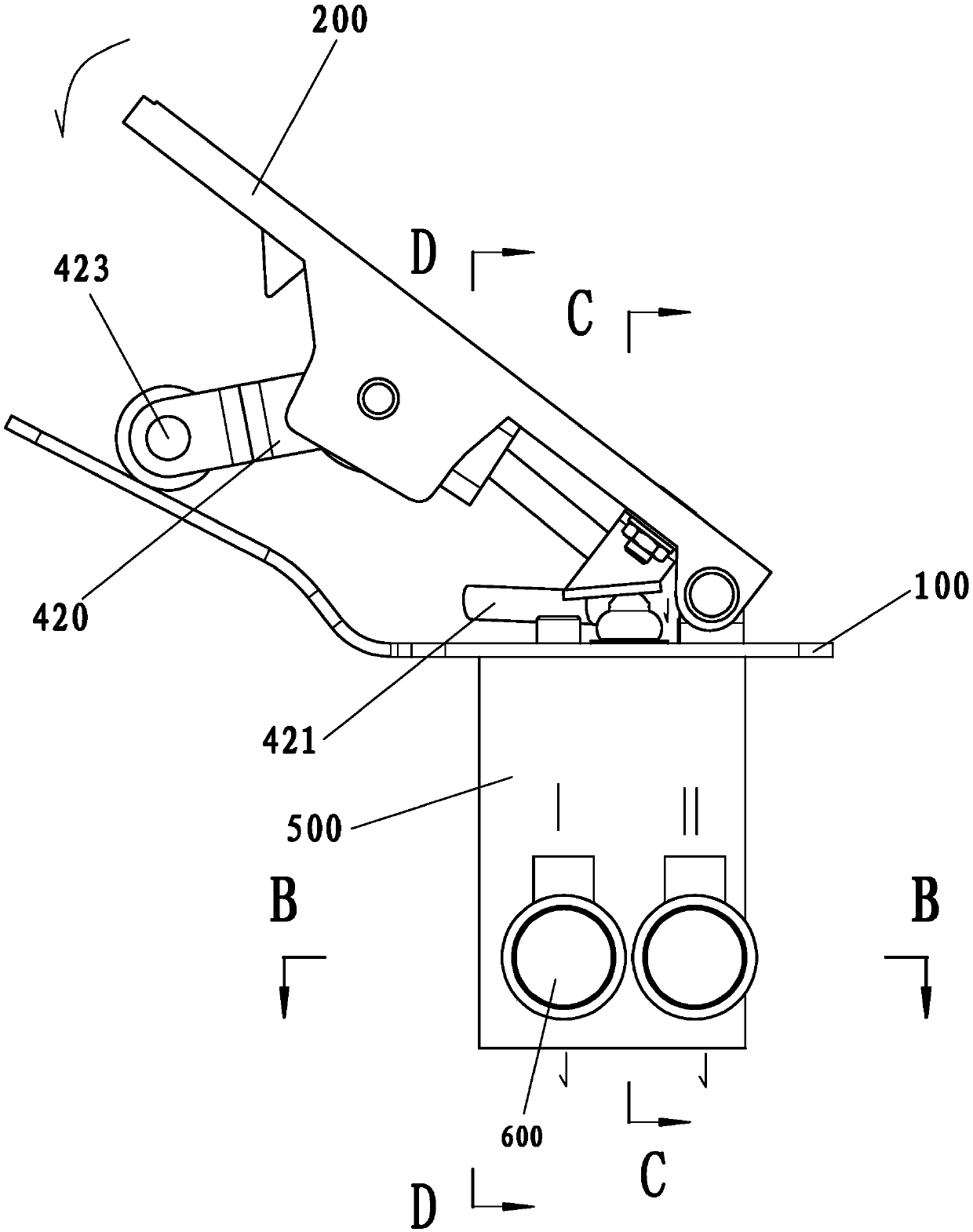

[0052] Such as Figure 1 to Figure 11 As shown, in this embodiment, the combined accelerator and travel control valve assembly mainly includes a pedal mounting seat 100 , a pedal body 200 , and a combined accelerator and travel control valve 300 .

[0053] The throttle and travel control combined valve 300 mainly includes a throttle control device 400 , a travel control combined valve 500 , and a travel direction control solenoid valve 600 .

[0054]The throttle control device 400 mainly includes a reset mechanism and a throttle opening control mechanism 420 .

[0055] The travel control combination valve 500 mainly includes an outer valve body 510 , a combination valve core 512 , a combination return spring 513 and a combination valve control part 514 .

[0056] The traveling direction control solenoid valve 600 mainly includes a solenoid valve body 610, a solenoid valve core 620, an electromagnetic return spring 624 and a solenoid valve control part.

[0057] Preferably, t...

Embodiment 2

[0109] This embodiment also includes an inner valve body 511 , the inner valve body 511 is located in the combined spool chamber 510 b, and the other free end of the outer return spring 5131 pushes against the inner valve body 511 . Through the inner valve body 511, the combination valve oil inlet cavity 510a, the combination valve core cavity 510b, the combination valve distribution cavity 510c and the combination valve oil return cavity 510d can be communicated.

[0110] Preferably, the top of the inner valve body 511 is provided with an inner valve body through hole 5123a adapted to the inner valve core 5122, and the inner valve core lower boss 5122e of the inner valve core 5122 extends into the inner valve body 511, and the inner valve core 5122 The concave part of the inner valve core of the core 5122 and the upper boss 5122d of the inner valve core can freely pass through the through hole 5123a of the inner valve body. When the inner spool 5122 moves down to the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com