Radial cage for bearings having high rotational speeds

A cage, axial technology, used in bearings, bearing components, roller bearings, etc., can solve the problems of shortening life, tearing of lubricating film, increasing friction, etc., to increase wear, optimize guiding effect, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

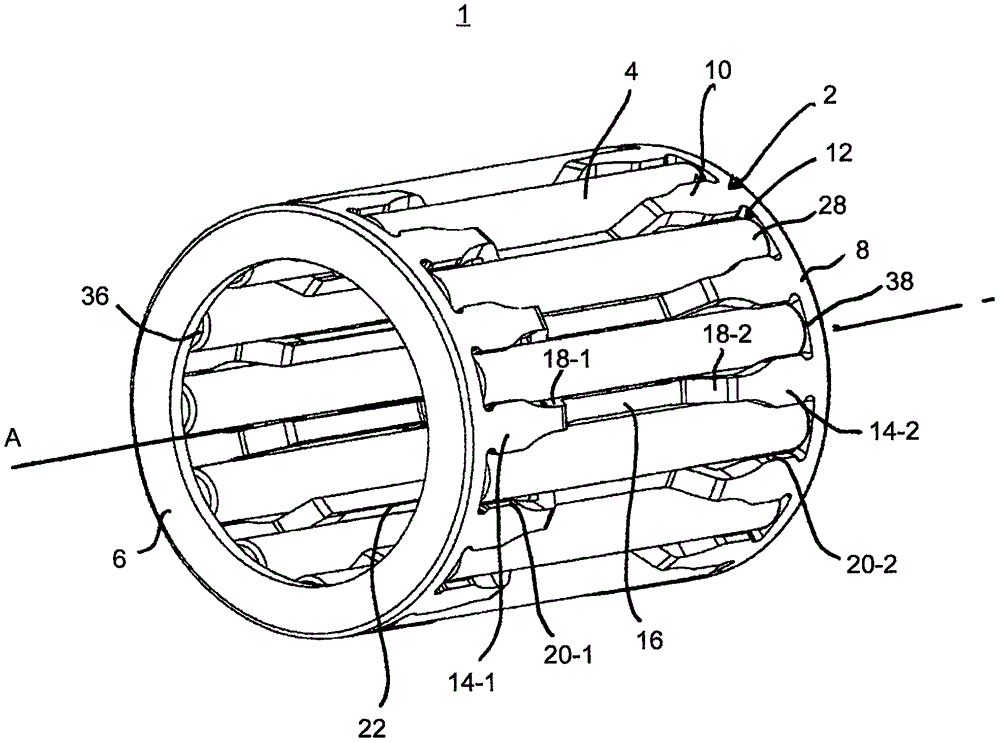

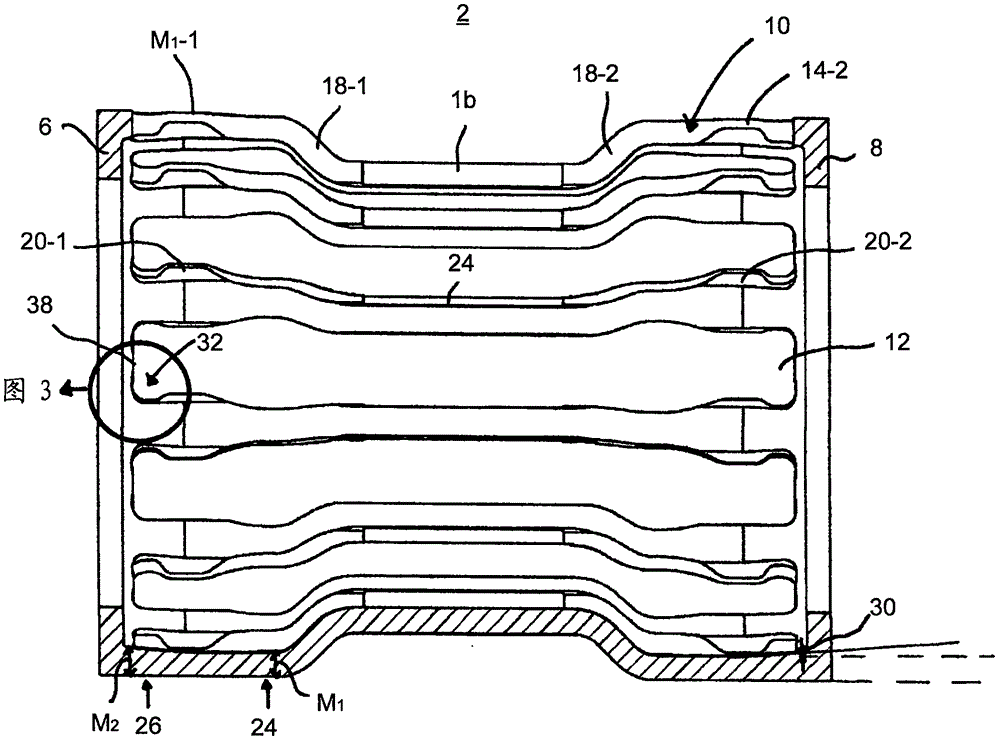

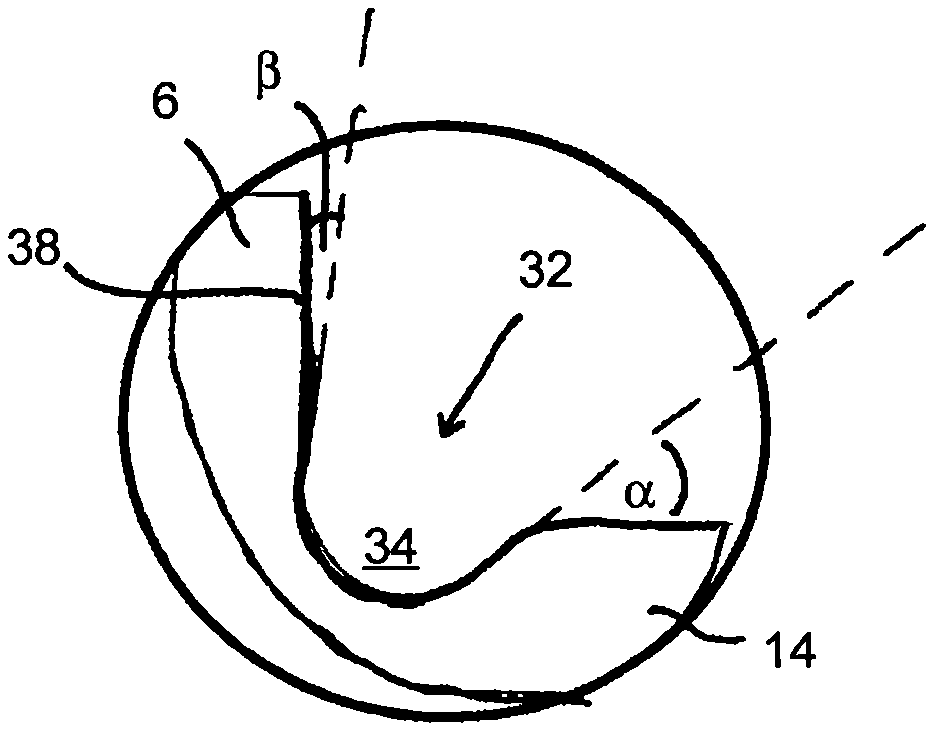

[0021] figure 1 A perspective view of a needle roller cage assembly 1 is shown, comprising a radial cage 2 and a roller 4 inside the radial cage. The radial cage 2 also has a first side ring and a second side ring 6, 8, which have a certain distance in the axial direction and are connected to each other by an axial beam 10, between which there is a space for accommodating the rollers 4. 12 pocket holes. remove figure 1 In addition to figure 2 It can be seen that the axial cross member 10 itself has side sections 14 - 1 , 14 - 2 which are respectively connected to the side rings 6 , 8 . In addition, the axial cross member 10 has a central section 16 which is connected to the side sections 14-1, 14-2 via lateral connection sections 18-1, 18-2. Wherein the side sections 14 - 1 , 14 - 2 and the middle section 16 are axial, and the connecting sections 18 - 1 , 18 - 2 are inclined to the rotation axis A of the bearing 1 .

[0022] The limit flanges 20, 22 installed on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com