Pressure release valve for conveyance of gas station

A technology of pressure relief valve and gas station, applied in the direction of safety valve, balance valve, valve device, etc., can solve problems such as fire, shutdown, air leakage of high pressure relief valve, etc., to reduce the possibility of shaking and ensure the service life , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

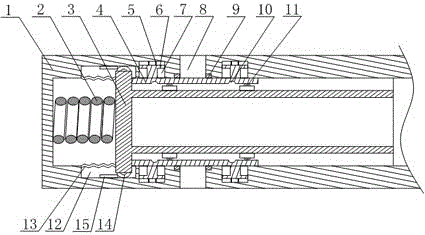

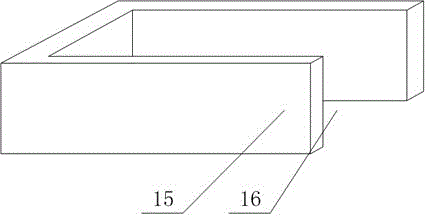

[0021] like figure 1 and figure 2 As shown, this embodiment includes a tubular casing 1 with one end closed and a piston 3 placed inside the casing 1, the piston 3 is a cylinder with one end closed, and the outer circumferential wall of the closed end of the piston 3 expands outward to Contact with the inner wall of the casing 1, and an annular space is formed between the main body of the piston 3 and the inner wall of the casing 1, and a first spring 2 is provided between the inner wall of the closed end of the casing 1 and the end face of the closed end of the piston 3 , at least one pressure relief hole 8 communicating with the annular space is opened on the casing 1, and two blind holes 7 are opened on the inner wall of the casing 1, and the two blind holes 7 are symmetrically arranged in the pressure relief hole 8. On both sides of the blind hole 7, there is a second spring 5. One end of the T-shaped movable block 6 is connected with the second spring 5 and is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com