Environment-friendly sealing sleeve for hough nodes

A technology of sealing sleeves and half-sections, applied in the direction of pipes/pipe joints/pipes, mechanical equipment, pipe components, etc., can solve problems such as breeding bacteria and polluting water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

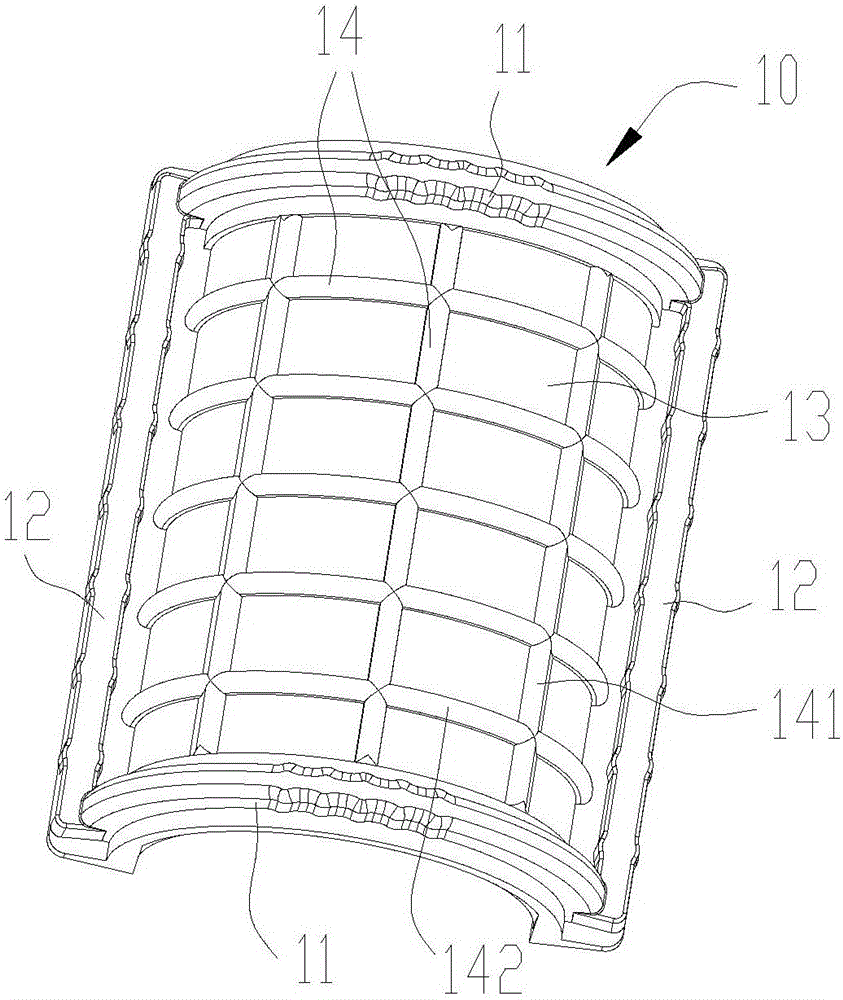

[0013] combine image 3 , the sealing sleeve includes two sealing rubber sleeve halves 10, the sealing rubber sleeve half body 10 includes semi-arc sealing strips 11 at both ends and sealing edge strips 12 on both sides, semi-arc sealing strips 11 and sealing edge strips 12 There is a sleeve body 13 with a circular arc surface in between, and grid-shaped ribs 14 are arranged on the outer wall of the sleeve body 13. The outer peripheral surface of the cross-section of the semi-circular arc sealing strip 11 has a large diameter in the middle section. The sealing strip 111, the small-diameter transition steps 112 on both sides, the ribs 14 extending to the semi-arc sealing strip 11 at both ends are connected to the transition step 112, the semi-arc sealing strip 11, the casing 13 and the outer surface of the covered pipe 1 The tube wall is directly attached to the fit.

[0014] The two ends of the ribs 14 should not be directly connected to the large-diameter sealing strip 111 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap