High pressure turbine guide vane chord width measuring tool

A technology of guide vanes and high-pressure turbines, applied in the field of measuring tools, can solve the problems of increasing production costs, reducing the production qualification rate of high-pressure turbine guide vanes, and difficulty in reading measurement values by inspectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

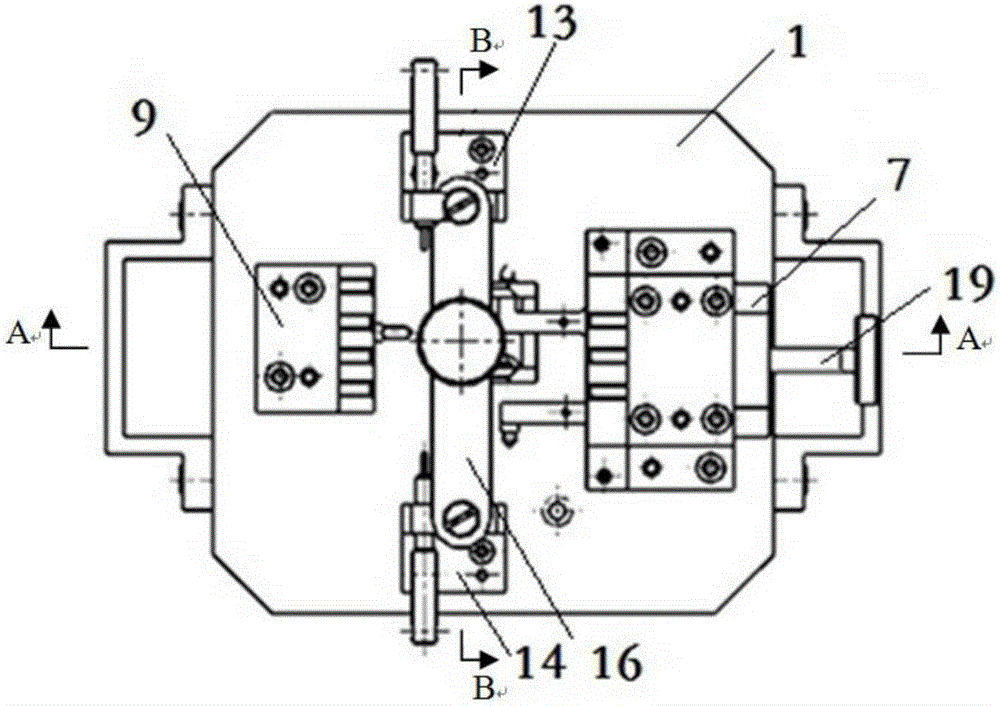

[0034] In conjunction with accompanying drawing, the present invention is described in further detail:

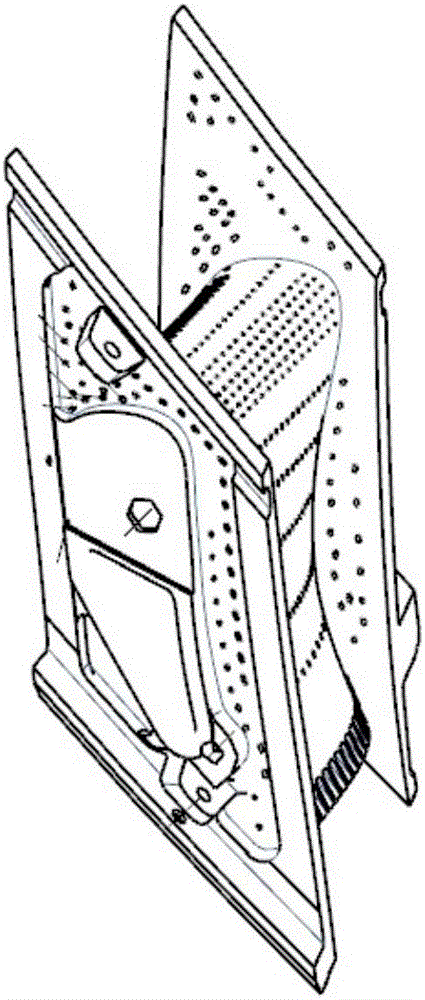

[0035] like image 3 As shown, the present invention provides a chord width measuring tool for a guide vane of a high-pressure turbine, which includes a bottom plate 1 , and handles 17 are respectively installed on the left and right sides of the bottom plate 1 . Two L-shaped supports are installed symmetrically at the longitudinal ends of the middle position of the bottom plate 1. The two L-shaped supports are respectively the first support 12 and the second support 13. A rotary pressure plate 16 is passed between the two L-shaped supports. connect. A first round head compression screw is installed in the middle of the rotary pressure plate 16, and a rubber pressing block 17 is installed at the end of the first round head compression screw for longitudinally compressing the blade. Bolts are respectively installed above the left ends of the two L-shaped supports, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com