Method for judging defects of flash memory plastic packaging device based on acoustic scanning

A method for judging defects and a technology for defect determination, applied in scientific instruments, instruments, material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of cumbersome operation, repeated acoustic scanning detection steps, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The flash memory plastic packaging device selected in the present invention is the EPCS16SI16N model of Altera Company. EPCS16SI16N is a flat-package plastic device, with a total of 50 samples, and the samples are numbered. In combination with specific actual cases, a method for judging defects of flash memory plastic packaging devices based on acoustic scanning described in the present invention will be described in detail.

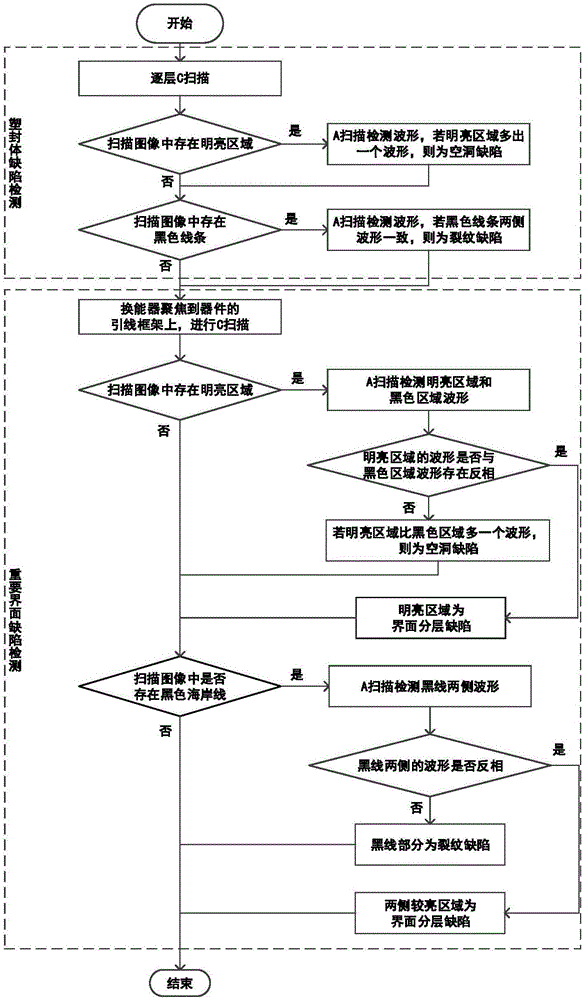

[0028] A method for judging defects of flash memory plastic packaged devices based on acoustic scanning in the present invention, the flow chart of which is as follows figure 1 As shown, the specific implementation steps are as follows:

[0029] Step 1: C-scan layer by layer. Layer-by-layer C-scanning is to check whether there are cracks or voids in the plastic package. Because interface delamination only occurs at the junction of different parts inside the device, it is impossible to have interface delamination inside the plastic package. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com