Machine tool control device and machine tool provided with the control device

A technology for a control device and a machine tool, applied in the field of machine tools, can solve the problem of not considering the vibration frequency, etc., and achieve the effects of preventing the shortening of the life, suppressing the load, and simplifying the control program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

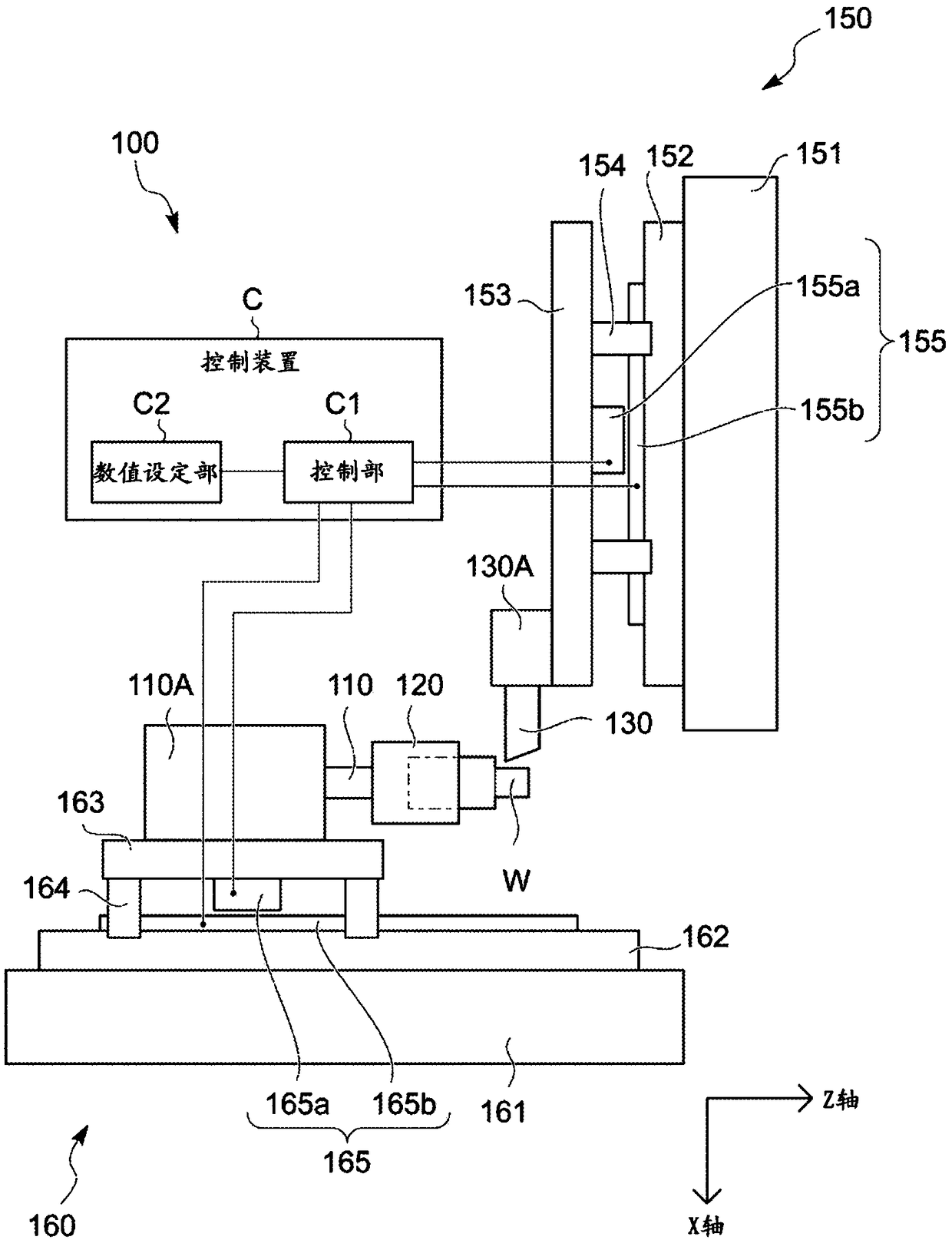

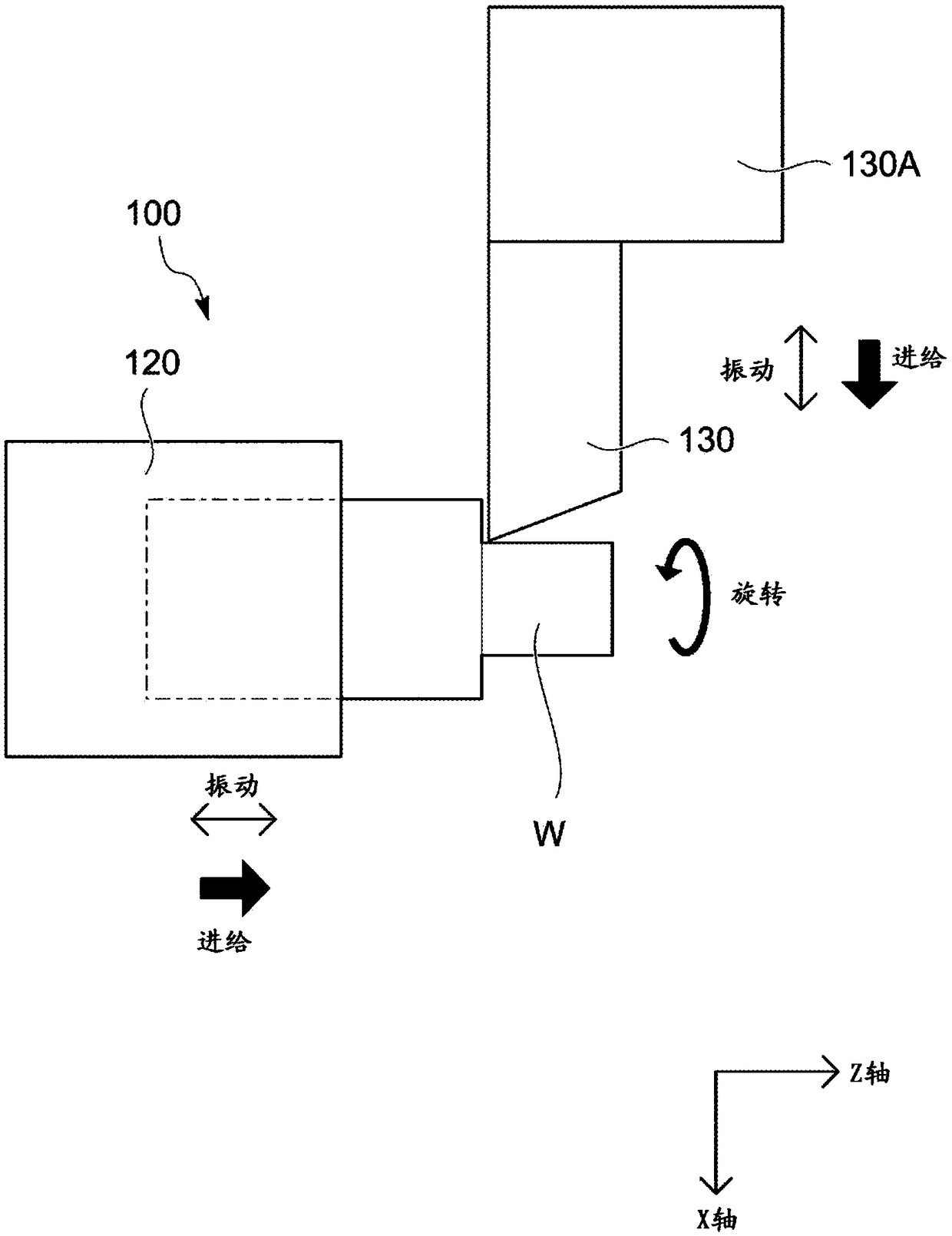

[0041] figure 1 It is a figure which shows the outline|summary of the machine tool 100 provided with the control apparatus C of 1st Example of this invention.

[0042] The machine tool 100 includes a spindle 110 and a cutting tool table 130A.

[0043] A chuck 120 is provided at the front end of the spindle 110 .

[0044] The workpiece W is held by the spindle 110 via the chuck 120 , and the spindle 110 constitutes a workpiece holding unit for holding the workpiece.

[0045] The spindle 110 is supported by the headstock 110A so as to be rotationally driven by the power of a spindle motor (not shown).

[0046] As the above-mentioned spindle motor, a conventionally known built-in motor or the like formed between the headstock 110A and the spindle 110 in the headstock 110A can be considered.

[0047] The headstock 110A is mounted on the bed side of the machine tool 100 so as to be movable in the Z-axis direction serving as the axial direction of the spindle 110 by the Z-axis di...

Embodiment 2

[0156] For the second embodiment, most of the elements are common to the first embodiment, so the detailed description of the common matters will be omitted, and the differences will be described below.

[0157] In the machine tool 100 of the second embodiment, the vibration number N can be fixed in advance (no need to input), the user only sets the rotation speed S, and the vibration frequency f is set according to the rotation speed S and the vibration number N, and the rotation speed S or The vibration number N is corrected.

[0158] On the other hand, in order to shorten the machining cycle, it is preferable to set the rotation of the main shaft 110 as high as possible.

[0159] For this reason, it is necessary to increase the vibration frequency f as much as possible, but it is not easy to set it too high from the viewpoint of stability control or the like.

[0160] Therefore, the rotational speed S can be increased as much as possible by reducing the vibration number N ...

Embodiment 3

[0171] For the third embodiment, most of the elements are common to the first embodiment and the second embodiment, so the detailed description of the common matters will be omitted, and the differences will be described below.

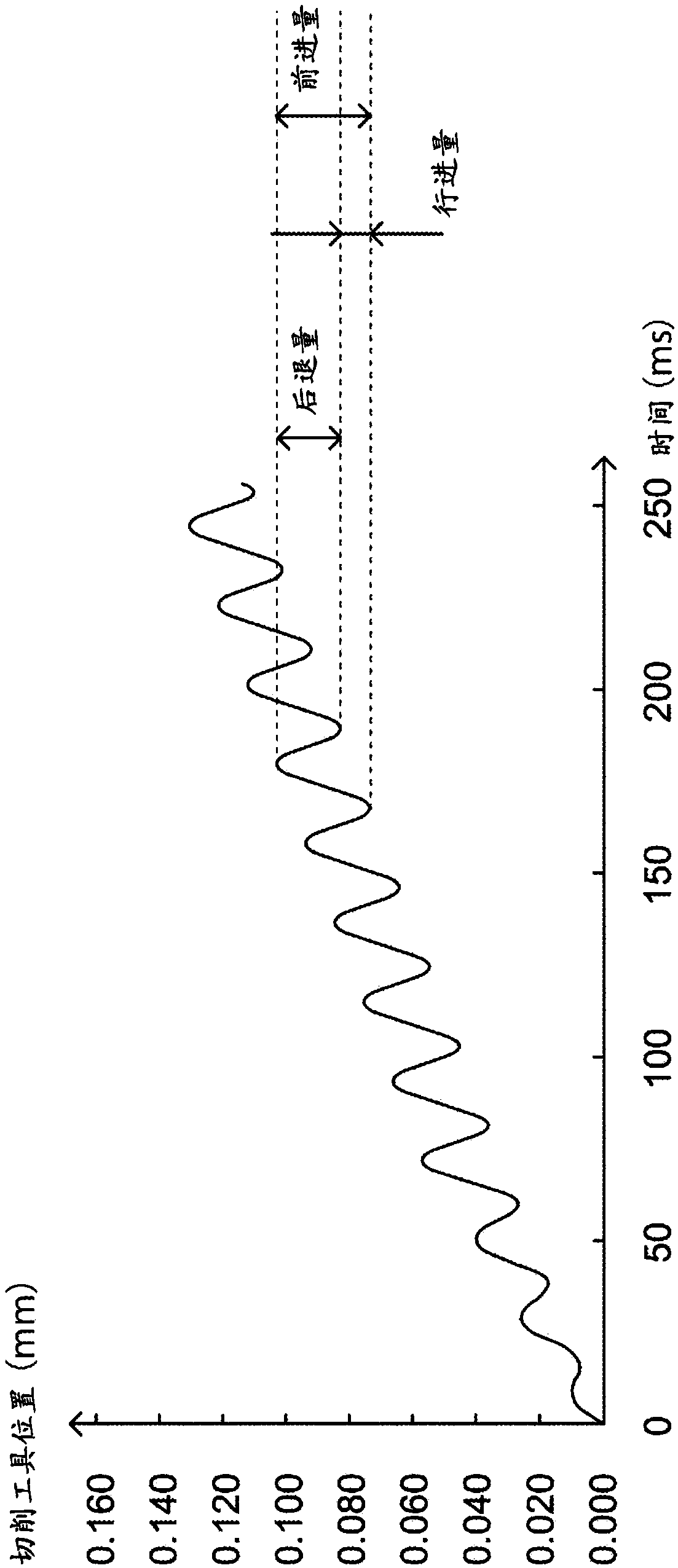

[0172] The existing machine tools described in Patent No. 5139591 and Patent No. 5139592 are configured to gradually increase the amplitude of the reciprocating vibration of the cutting tool until it reaches a predetermined value when a series (one process) of turning operations of turning the workpiece is started. Determine the specified vibration amplitude.

[0173] However, since it is not disclosed specifically how to increase, there is a problem that it is not easy to change the increase state as needed.

[0174] Therefore, the object of the invention of the third embodiment is to provide a method for simplifying the control program for gradually increasing the amplitude of the reciprocating vibration of the cutting tool until it reaches a predet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com