Forming cutter for machining arc-shaped holes and cutter machining method

A technology for forming knives and arc-shaped holes, which is applied in the direction of tools, manufacturing tools, and metal processing equipment for lathes. The effect of high efficiency and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

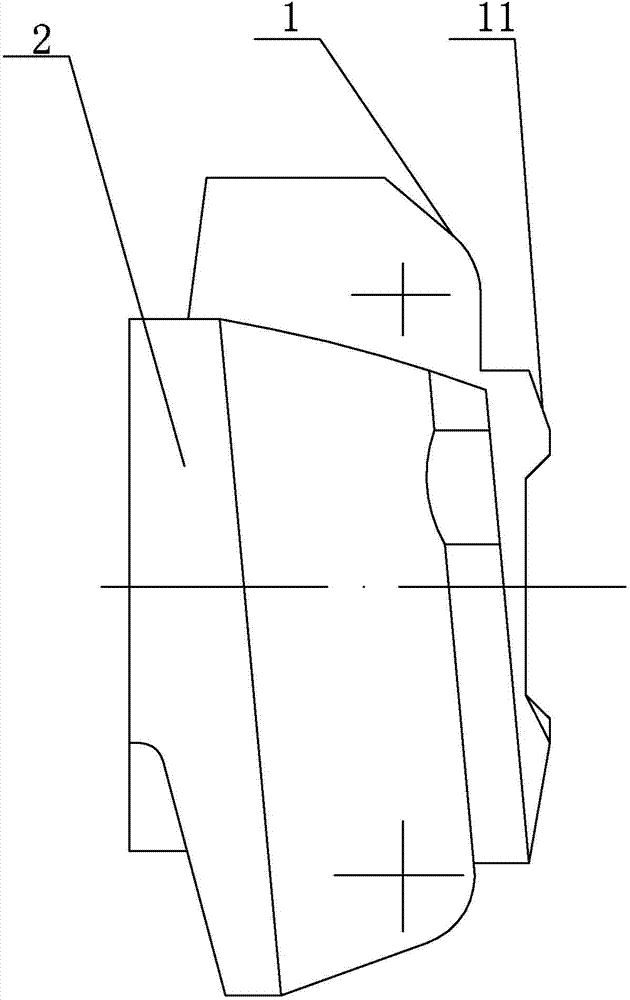

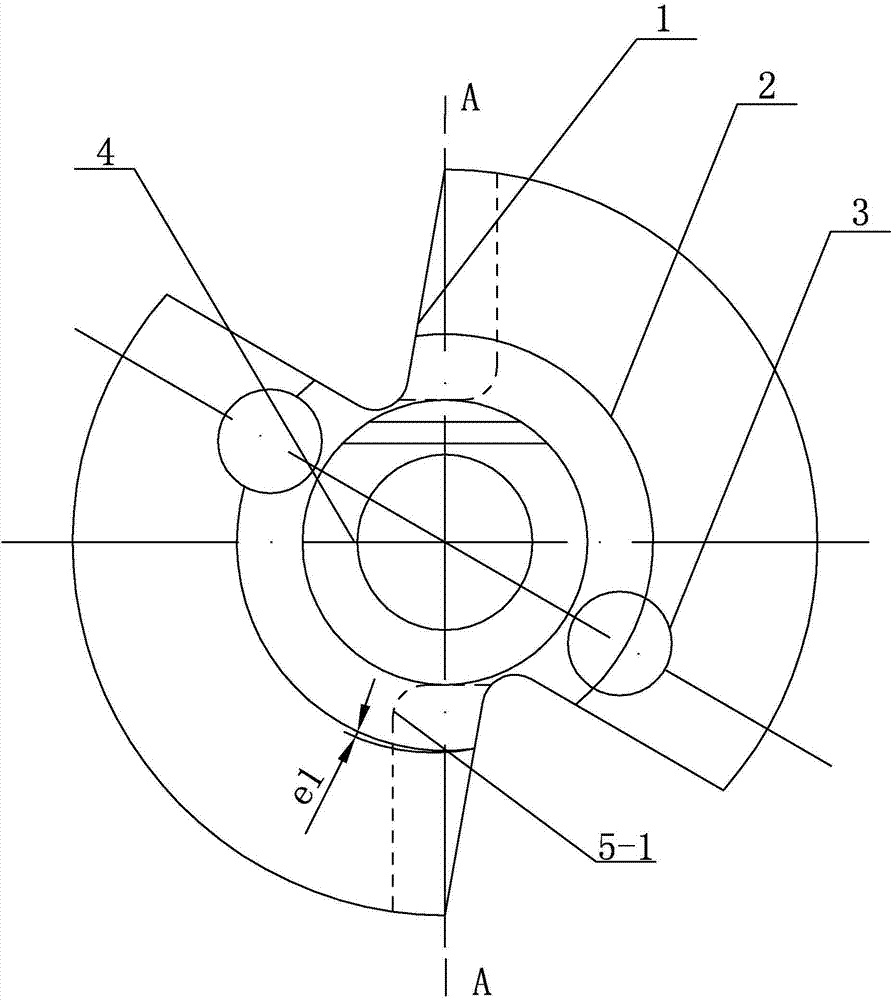

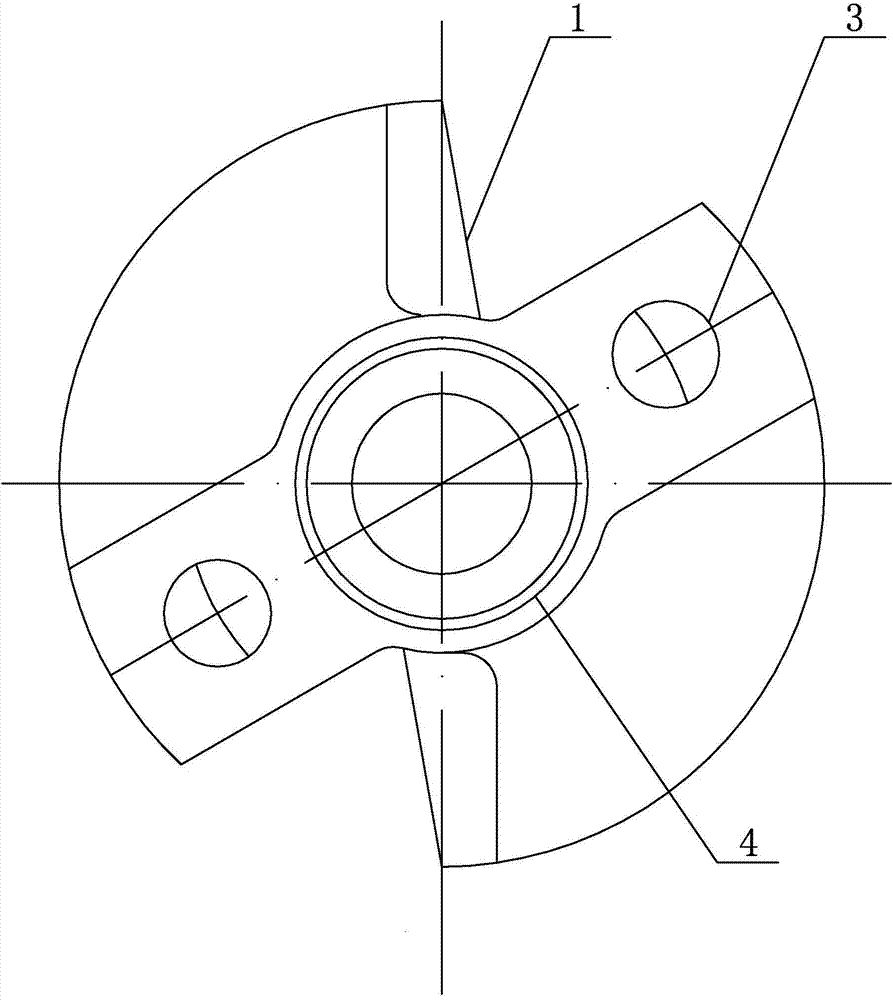

[0043] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment mode, a kind of forming knife and tool processing method for processing arc-shaped hole described in this embodiment mode, it comprises cutter head 1 and blade body 2, and blade body 2 is cylinder, and is processed along the center line of blade body 2 There is a center line through hole 4, and the cutter head 1 includes two arc-shaped cutting edges 5, which are fixedly installed on the right end of the blade body 2, and the two arc-shaped cutting edges 5 are arranged symmetrically to the center.

specific Embodiment approach 2

[0044] Specific implementation mode two: combination Figure 1-Figure 7 Describe this embodiment, a kind of forming knife and tool processing method for processing arc-shaped hole described in this embodiment, described cutter head 1 also comprises a set of blades 11, and a set of blades 11 comprises two blades 11, two A blade 11 is fixedly mounted on the right side of the two arc-shaped cutting edges 5, two cylindrical through-holes 3 are processed in the axial direction on the blade body 2, and two V-shaped grooves are symmetrically processed on the blade body 2 and the cutter head 1 , the angle of each V-shaped groove is 60°, the centerline through hole 4 includes a first central hole 4-1 and a second central hole 4-2, and the right end of each V-shaped groove is located at the main arc-shaped cutting edge 5 At the cutting edge, a first arc edge 5-1 is processed between the main cutting edge and the secondary cutting edge of the arc cutting edge 5, and the radius of the fir...

specific Embodiment approach 3

[0045] Specific implementation mode three: combination Figure 4-Figure 7 This embodiment will be described. In this embodiment, a forming knife for machining arc-shaped holes and a cutting tool processing method, the value of R is 6.5 mm, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com