Power module

A power module and component technology, applied in the direction of electric components, transmission boxes, transmission parts, etc., can solve the problems of unfavorable use of small-volume robot machinery and equipment, large volume, and many parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

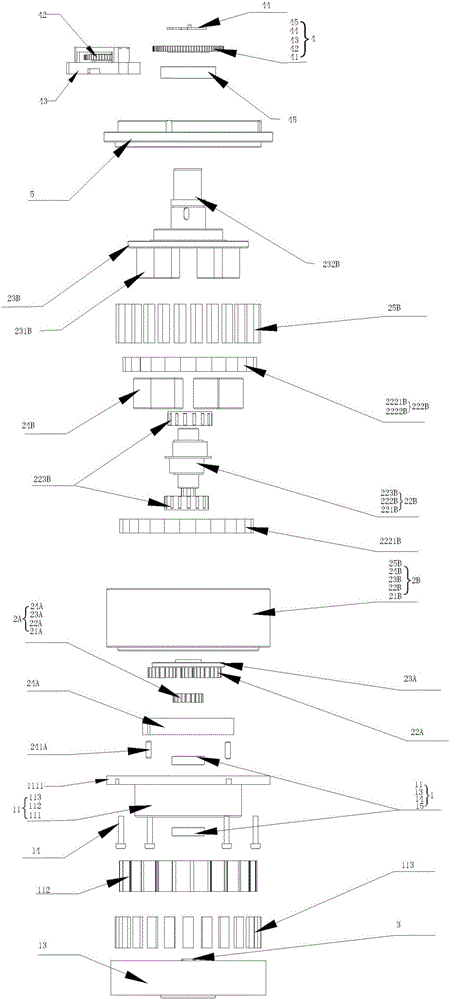

[0050] see figure 1 , the power module of this embodiment includes a motor 1, a planetary reduction mechanism 2A, a cycloidal reduction mechanism 2B and a motor output mechanism. In this embodiment, the motor 1 includes a stator assembly 11 and a motor outer rotor 13, and the motor outer rotor 13 is designed as Cylindrical hollow body structure, inside accommodates the stator assembly 11 embedded in the planetary reduction mechanism 2, the motor output shaft 3 is the motor output mechanism of this embodiment, and the motor output shaft 3 is located at the center of the stator assembly 11 and the motor outer rotor 13 position, and the motor output shaft 3 is the main rotational speed transmission mechanism of the entire motor 1 and the planetary reduction mechanism 2A.

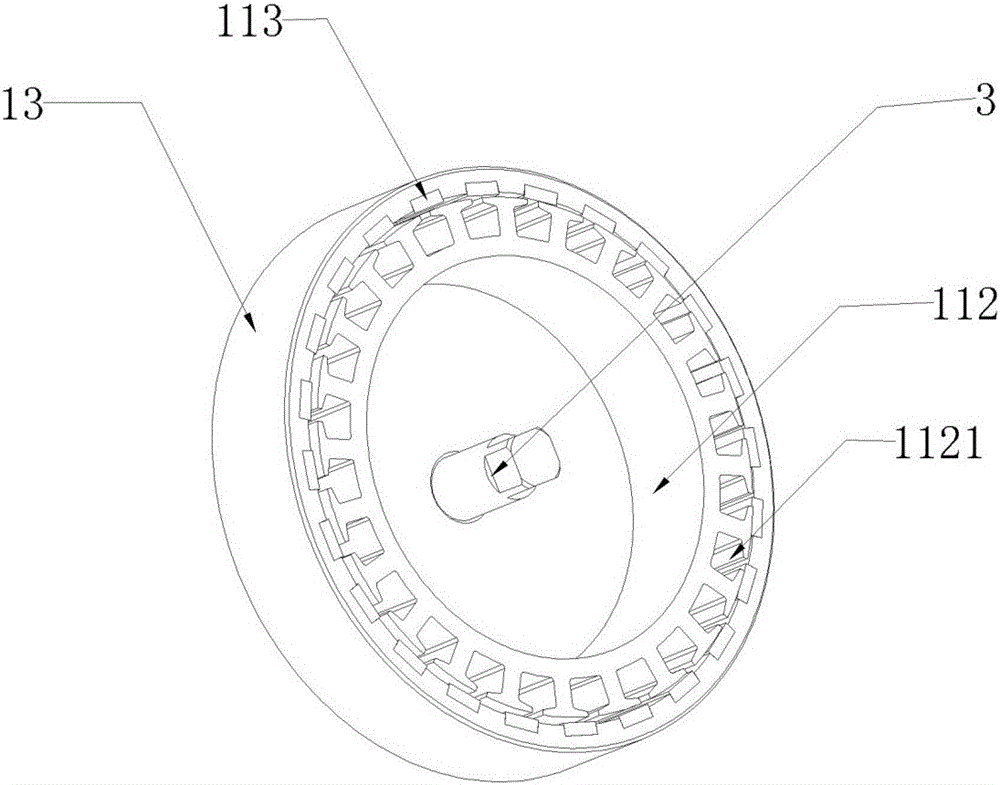

[0051] see further figure 2, in this embodiment, the stator assembly 11 includes a stator fixing flange 111, a stator iron core 112 and a magnetic steel 113, and the stator fixing flange 111 is also a cylindr...

no. 2 example

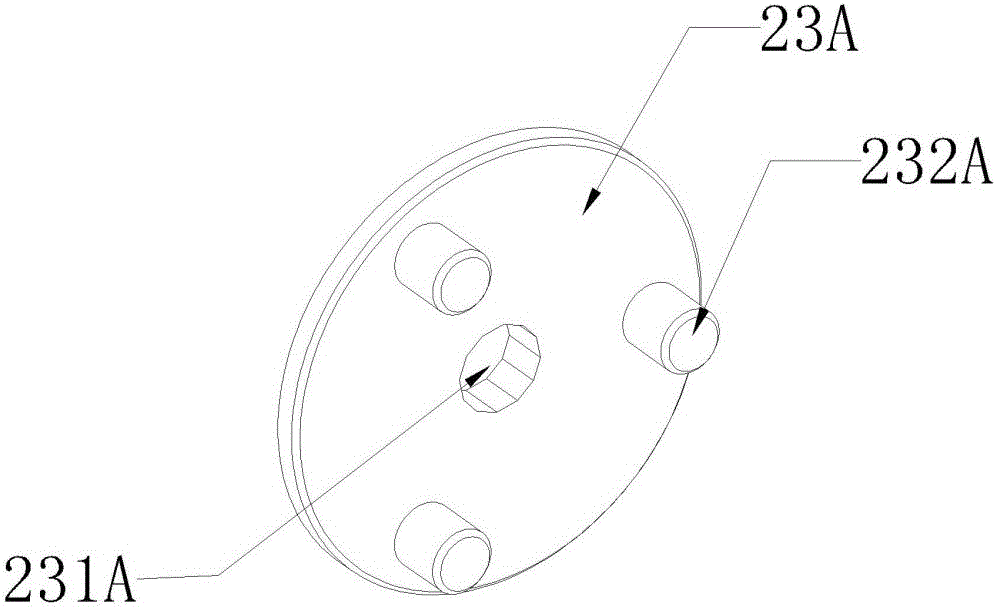

[0064] The above is a structure designed to use the planetary reduction mechanism 2A and the cycloidal reduction mechanism 2B together when a large reduction ratio is required. According to the actual field where the power module is used, the planetary reduction mechanism 2A can also be used alone. The specific connection The way is to accommodate the planetary reduction mechanism 2A in the stator assembly 11 of the motor 1. In this embodiment, the structure of the motor 1 is the same as that of the first embodiment, and the main structure of the planetary reduction mechanism 2A is also the same as that of the first embodiment. same, except that Figure 8 As shown, the structure of the planetary carrier 23A' of the planetary reduction mechanism 2A in this embodiment is different, wherein the structure of the fixed protrusion 232A' remains unchanged, but the central part of the planetary carrier 23A' is not provided with an output through hole structure, and It is a planetary o...

no. 3 example

[0066] In the case of a small reduction ratio requirement, a situation in which only the cycloidal reduction mechanism 2B is used is also designed. The specific connection method is: the stator fixing flange 111 is not limited to the design of a groove structure, and when no groove is designed In terms of structure, the connection structure of the entire cycloidal reduction mechanism 2B is the same as that of the first embodiment, the stator fixing flange 111 and the pin gear housing 21B are fixed by the fixing pin 14, and the motor output shaft 3 and the eccentric shaft 221B are connected by a coupling (not shown in the figure) Just connect, and other components remain unchanged. If the stator fixing flange 111 is designed with a groove structure, the inner wall of the groove can be designed as a concave-convex structure on the inner wall of the pin gear housing 21B, and the pin teeth 25B are accommodated in the stator fixing flange 111, and the pin gear housing 21B is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com