Small Shaking Cassava Harvester

A cassava and lifting frame technology, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of high rate of crushed potatoes, low production efficiency, low price, high labor intensity, etc., and achieves low rate of crushed potatoes and a wide range of uses , the effect of low usage fee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

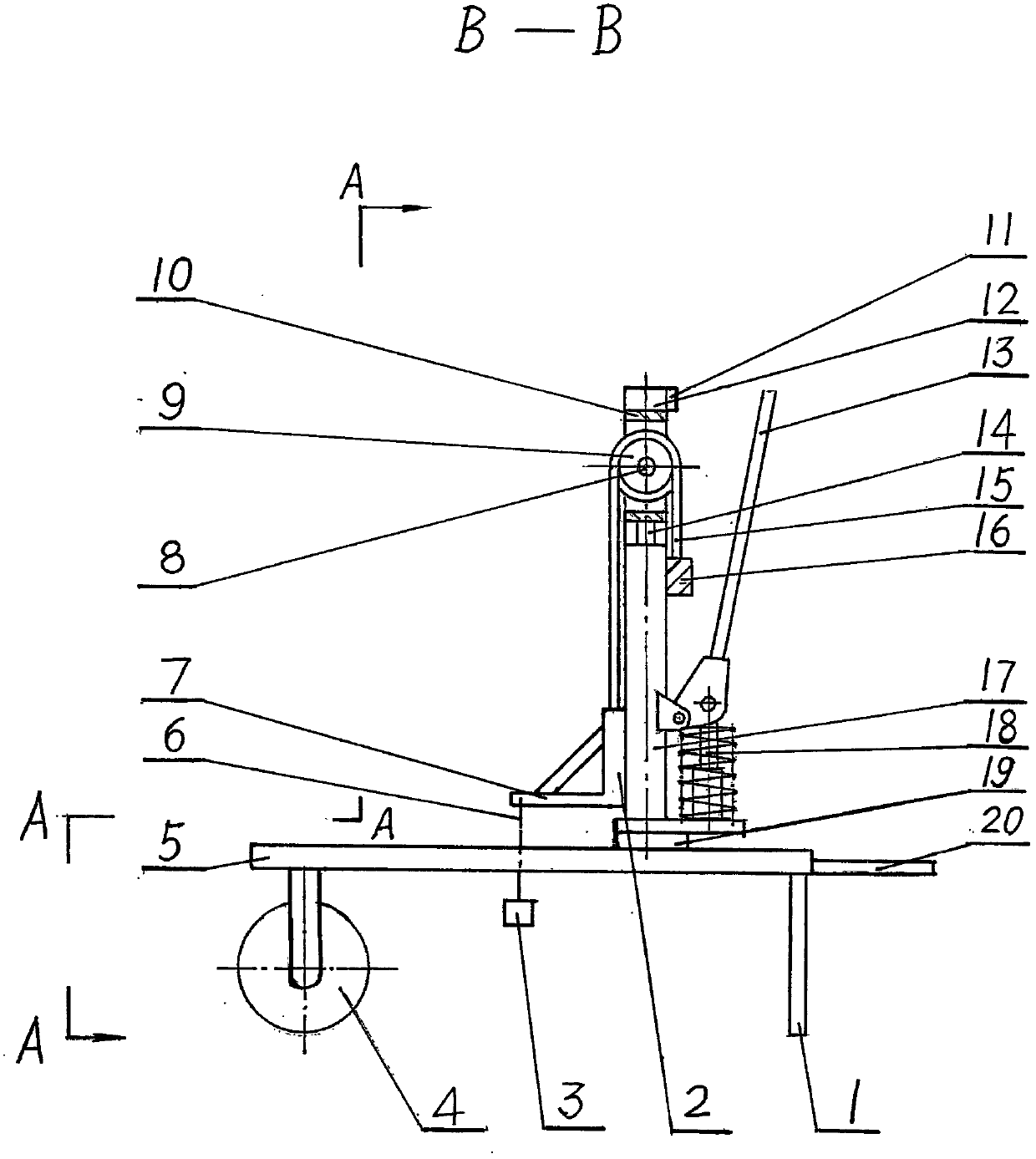

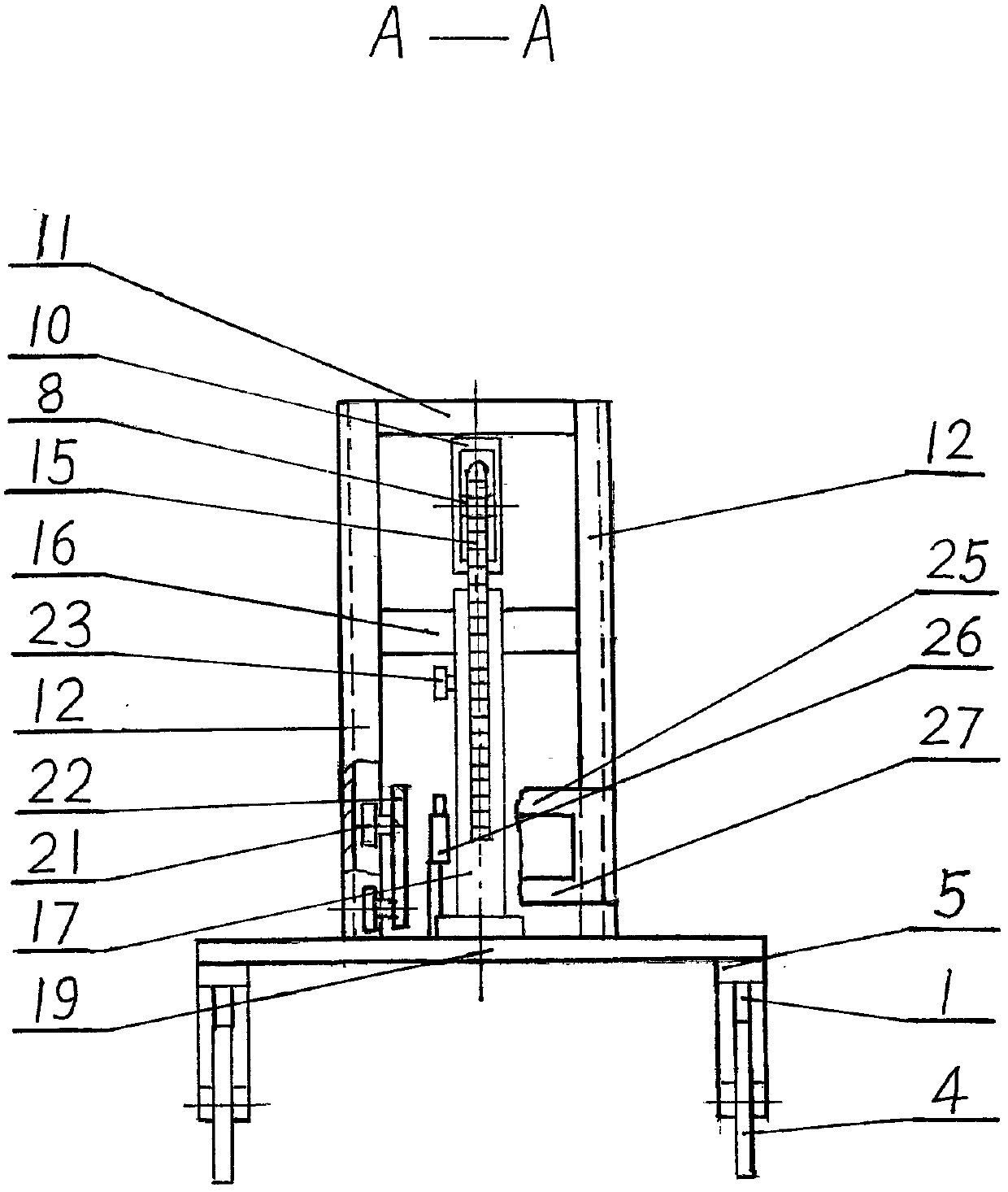

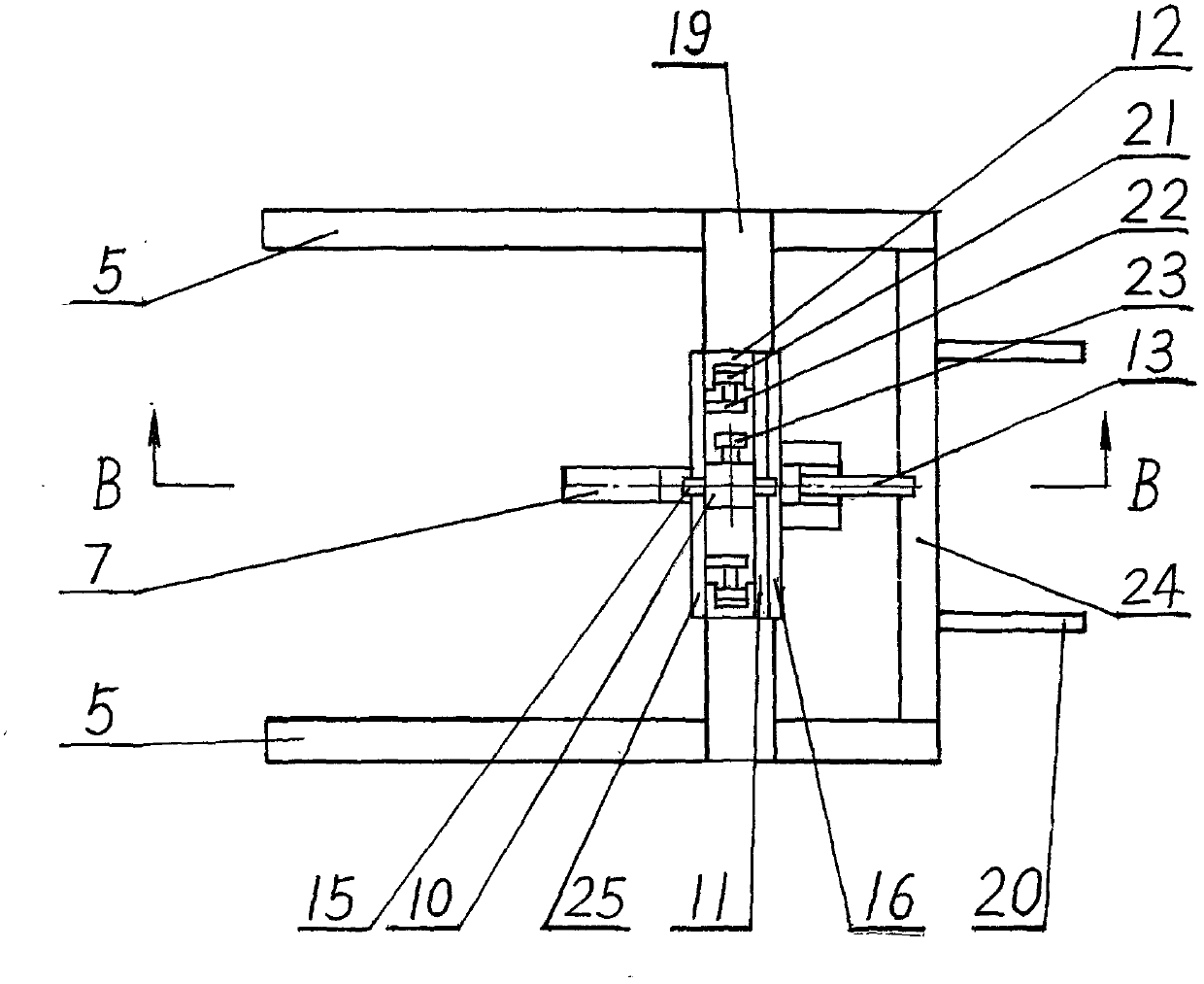

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4, pull the reversing valve handle 42, so that the reversing valve 26 is in the working state of the right position 41 of the reversing valve, the oil inlet P31 and the shaking oil outlet B40 are connected, the rising oil outlet A33 is closed, and the operating lever 13 is lifted. The small piston rod 18 moves upward, and the hydraulic oil in the oil tank 30 enters the small oil cylinder 44 through the oil suction pipe 29 and the oil suction check valve 45; the operating rod 13 is pressed down, the small piston rod 18 moves downward, and the hydraulic oil in the small oil cylinder 44 passes through the drain The oil pipe 28 enters the oil inlet P31, and flows out from the shaking oil outlet B40, and enters the oil inlet pipe 37 and the plunger cylinder 38 through the shaking oil pipe 39, and the hydraulic oil pushes the large plunger rod 14, the sprocket shaft 8, the sprocket 9, and the chain 15 , the sprocket seat 1...

Embodiment 2

[0023] refer to figure 1 , figure 2 , image 3 , Figure 5 , close the cut-off valve 46, the oil discharge pipe 28 and the shaking oil pipe 39 are not connected, when the operating rod 13 is lifted, the small piston rod 18 moves upward, and the hydraulic oil in the oil tank 30 enters the small oil cylinder 44 through the oil suction pipe 29 and the oil suction check valve 45; Lower the operating rod 13, the small piston rod 18 moves downward, the hydraulic oil in the small oil cylinder 44 enters the ascending oil pipe 34 through the oil discharge pipe 28, the oil discharge check valve 35 enters the oil inlet pipe 37 and the plunger cylinder 38, and the hydraulic oil pushes the large The plunger rod 14, the sprocket shaft 8, the sprocket 9, the chain 15, and the sprocket seat 10 move upwards, so that the elevating frame 2, the boom 7, the flexible member 6, and the fast stem holder 3 move upwards to pull up the cassava , that is, the fast shaking type hydraulic jack 17 real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com