Small shaking type cassava harvester

A harvester and cassava technology, applied to digging harvesters, harvesters, excavators, etc., can solve the problems of high potato crushing rate, root damage, low production efficiency and low price, and achieve low usage fee and small potato crushing rate , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

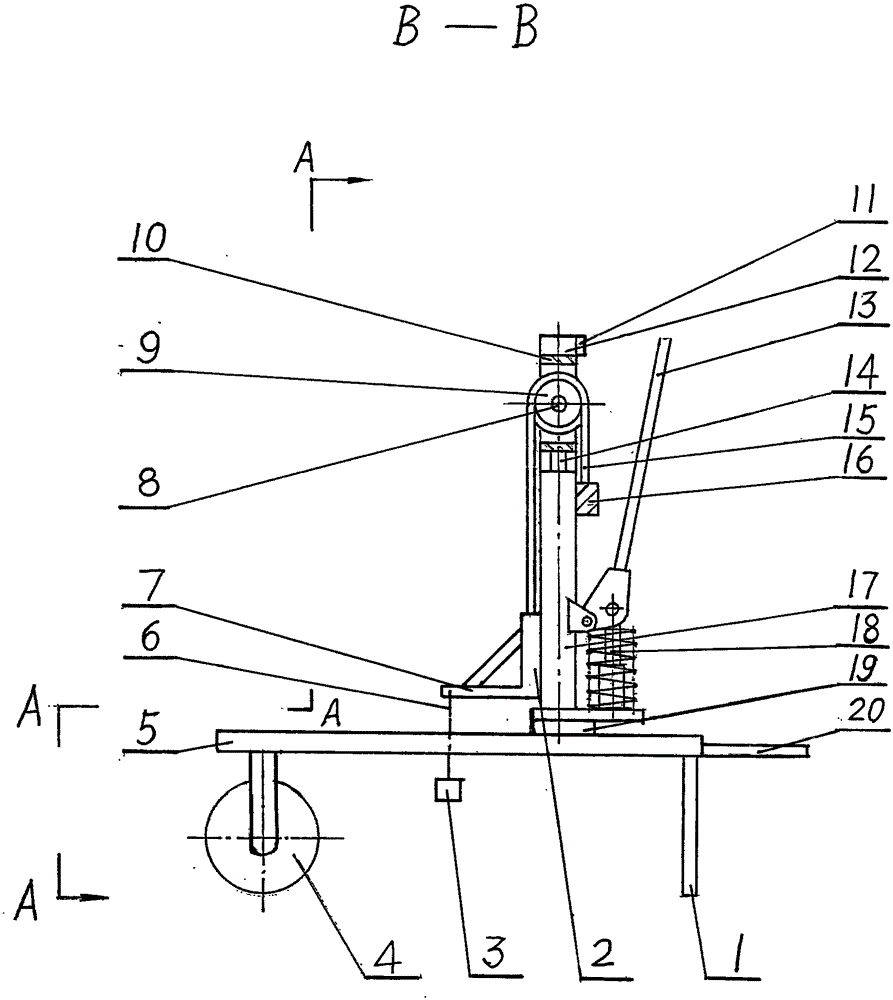

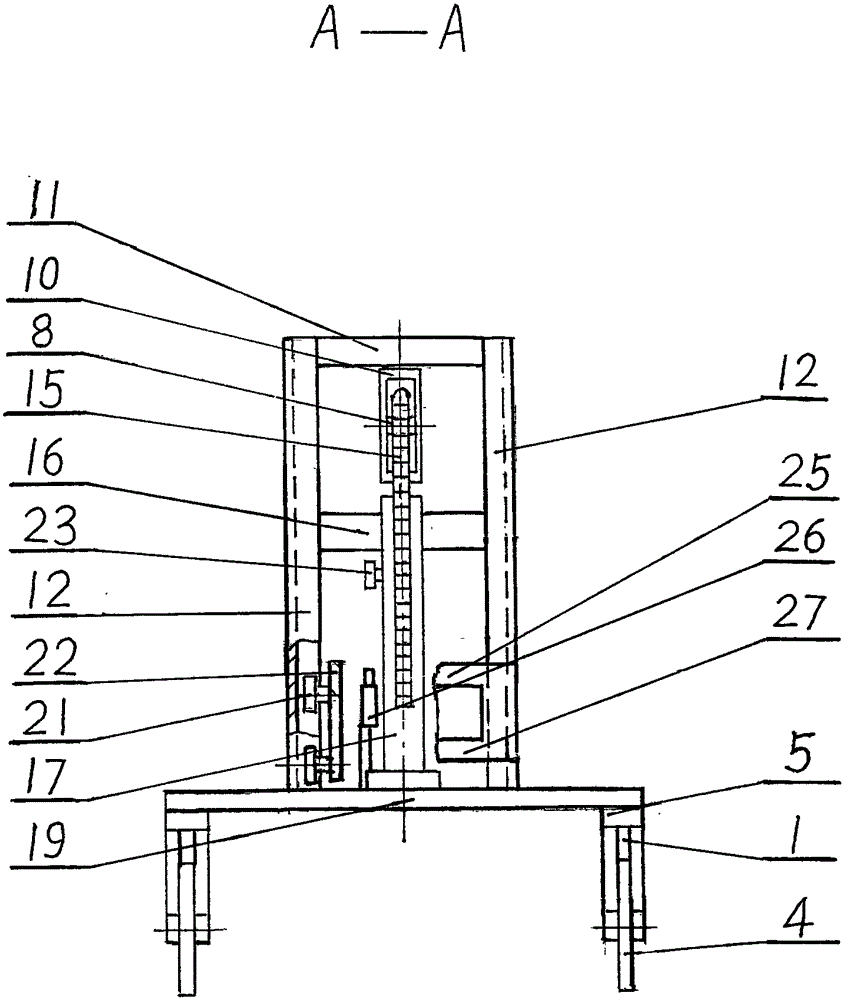

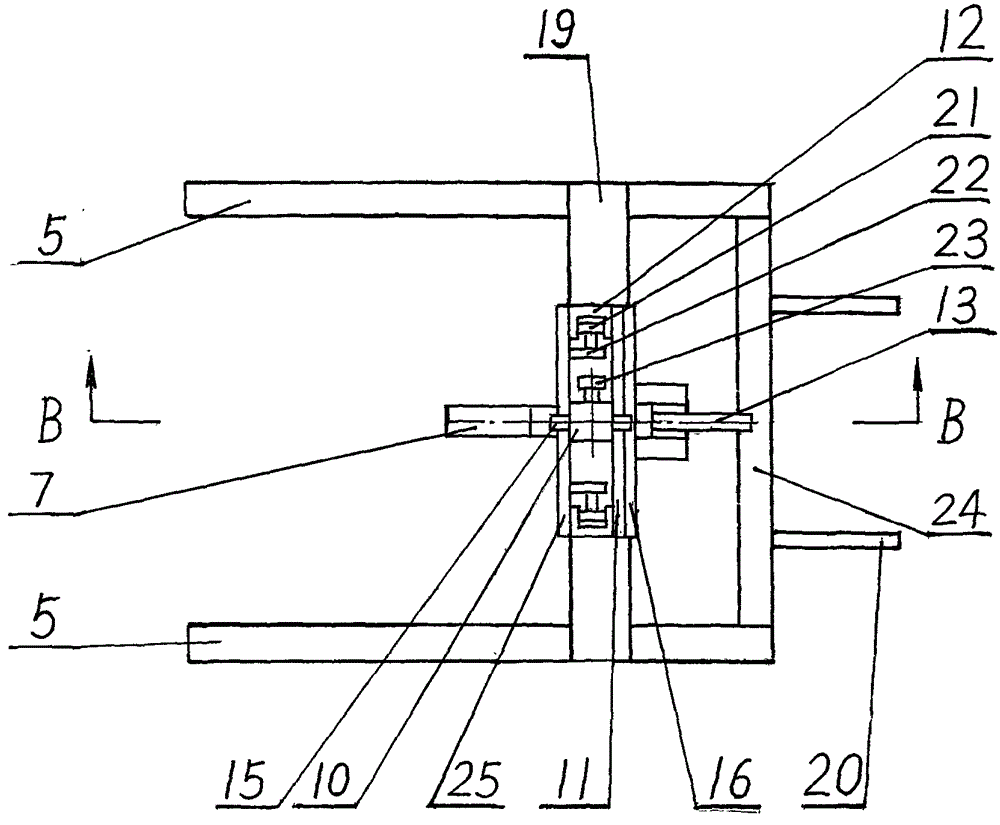

[0017] refer to figure 1 , figure 2 , image 3 , Figure 4, pull the reversing valve handle [42], when the reversing valve [26] is in the working state of the right position of the reversing valve [41], the oil inlet P[31] and the shaking oil outlet B[40] are connected, Lift the oil outlet A[33] to close, lift the operating rod [13], the small piston rod [18] moves upward, and the hydraulic oil in the oil tank [30] enters the small oil cylinder through the oil suction pipe [29] and the oil suction check valve [45] [44]; depress the operating rod [13], the small piston rod [18] moves downward, and the hydraulic oil in the small oil cylinder [44] enters the oil inlet P [31] through the oil discharge pipe [28], and from the shaking The oil outlet B[40] flows out, and enters the oil inlet pipe [37] and plunger cylinder [38] through the shaking oil pipe [39], and the hydraulic oil pushes the large plunger rod [14], the sprocket shaft [8] and the sprocket [9] , the chain [15], ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com