Blockage-prevention type feeding device of sugarcane harvesting machine

A technology for feeding devices and harvesters, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as reducing the adaptability of sugarcane, blockage of conveying channels, damage to sugarcane skin, etc., to improve poor adaptability, reduce blockage and The effect of breaking and reducing the impurity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

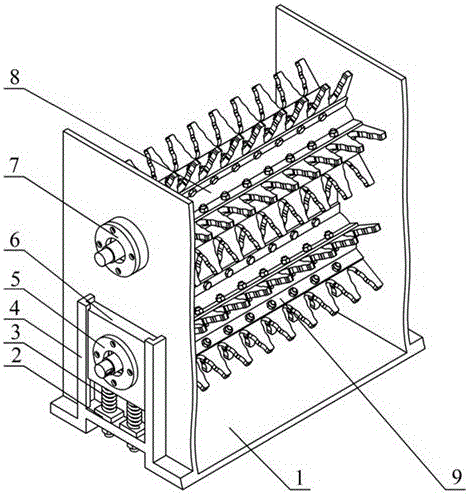

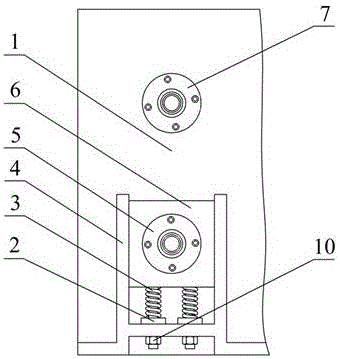

[0021] Such as figure 1 and figure 2 The shown sugarcane harvester anti-clogging feeding device mainly includes a frame 1, a gasket 2, an adjustment spring 3, a chute 4, a lower end cover 5, a slider 6, an upper end cover 7, an upper feeding roller 8, Lower feed roller 9 and adjusting bolt 10. The structure of the upper feeding roller 8 and the lower feeding roller 9 is basically the same, including: a power input shaft 11 , a roller frame 12 , a clamping plate 13 , bolts 14 and a conveying element 15 . The upper feeding roller 8 is installed on the frame 1 through the upper end cover 7, and the lower feeding roller 9 is installed on the frame 1 through the slider 6, and the lower end of the slider 6 is connected with the adjustment spring 3.

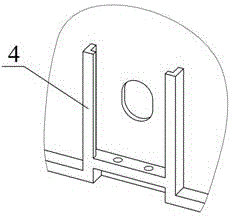

[0022] Such as image 3 As shown, the lower end of the frame 1 is provided with a track-shaped hole, the two ends are chute 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com