Field machine for straw smashing and stubble cleaning through biaxial reverse rotation

A technology of straw crushing and stubble removal, which is applied to harvesters, crop processors, agricultural machinery and implements, etc. It can solve problems such as unfavorable soil absorption and fermentation, single operation mode, and sowing congestion, so as to enhance the effect of rotary tillage and operation effect Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

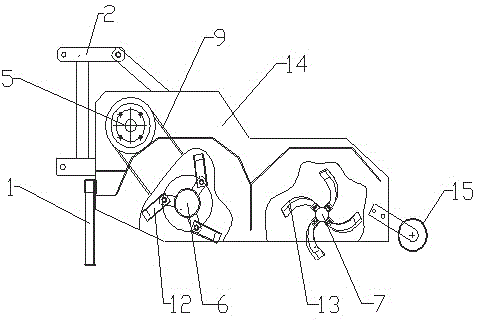

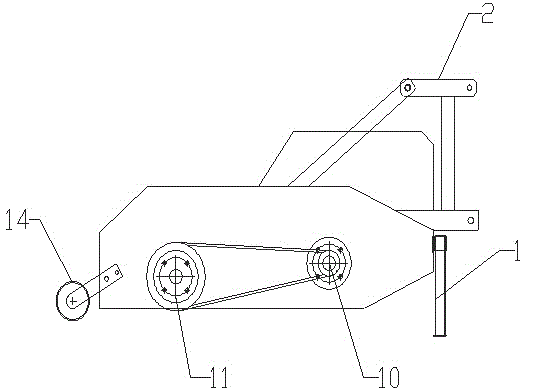

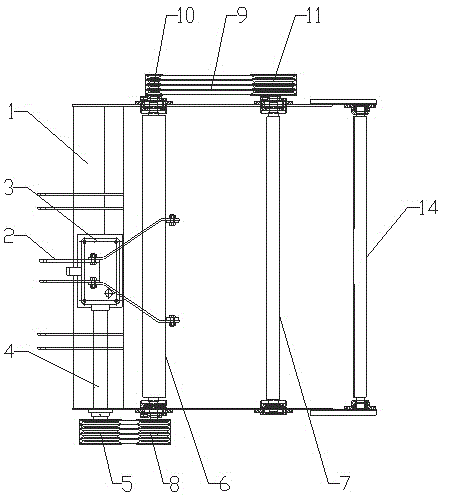

[0020] Accompanying drawing is the specific embodiment of the present invention. Such as figure 1 As shown, this kind of straw crushing double-axis reverse stubble removal machine includes a frame assembly 1. The front end of the mechanism assembly 1 is provided with a suspension 2. The suspension 2 is used to connect with the tractor. The middle position of the front end of the frame assembly 1 is Gear box 3 is set, the power output shaft of the tractor drives the gear box 3 through the coupling, the power output shaft of the gear box 3 is connected to the transmission shaft 4, a large pulley 5 is arranged at the outer end of the transmission shaft 4, the rear of the transmission shaft 4 is from the front To the rear, a stubble cutter shaft 6 and a rotary tiller shaft 7 are successively arranged, and one end of the stubble cutter shaft 6 is provided with a small pulley 8, and the small pulley 8 and the large pulley 5 are located on the same side of the frame assembly 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com