Improved crown fruit bagging machine

A technology for bagging and fruiting, which is applied in plant protection covers, botanical equipment and methods, gardening, etc., and can solve the problems of easy-to-drop bags, affecting sealing, and falling down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

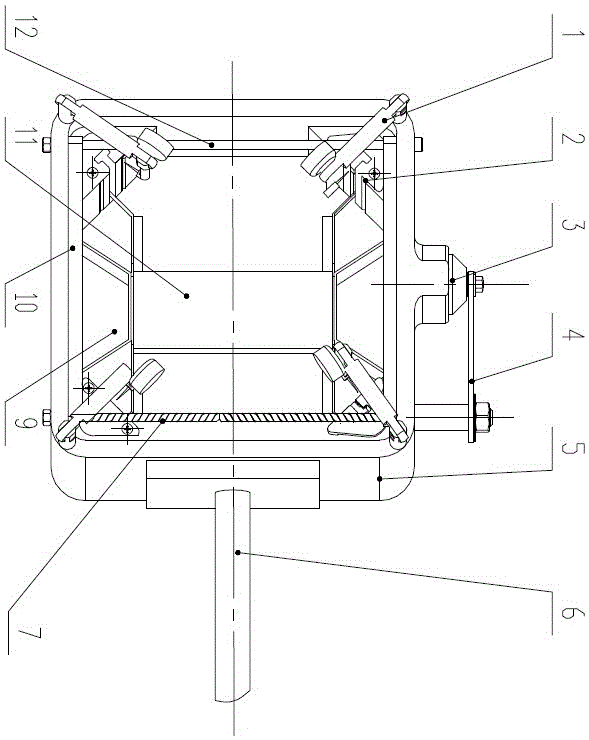

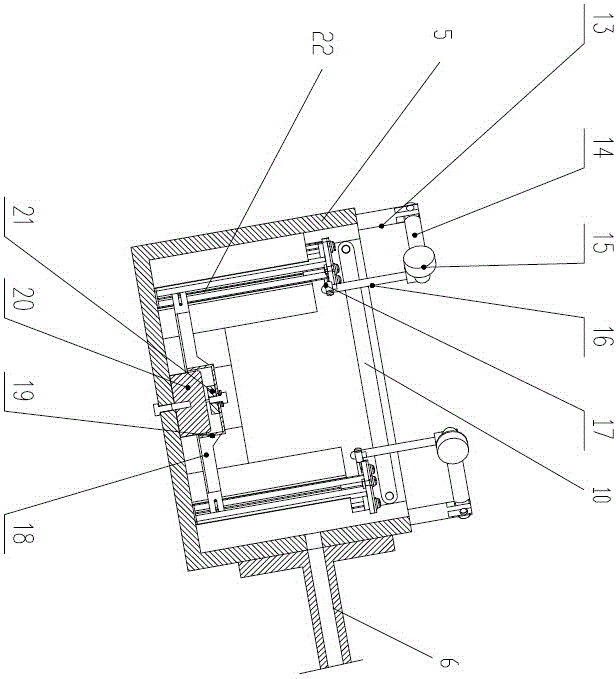

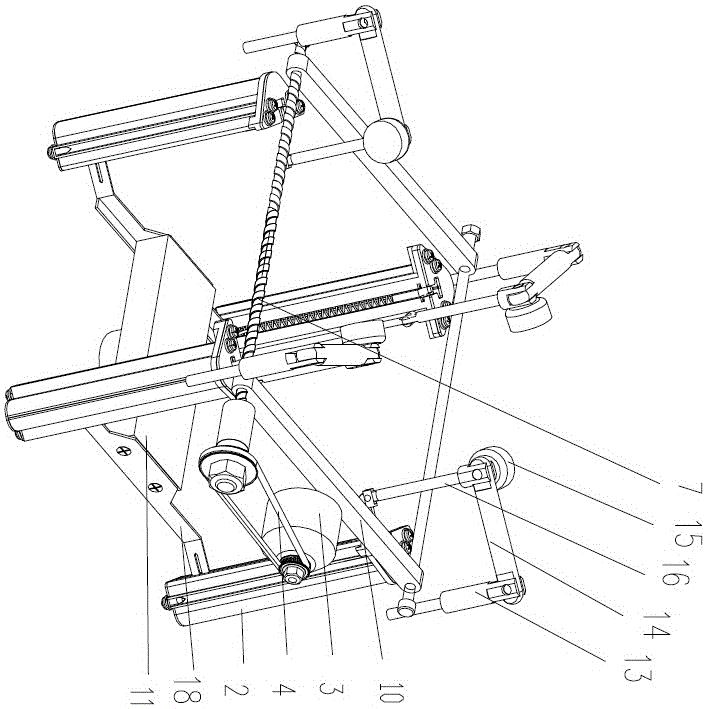

[0013] The canopy fruit bagging machine tool of present embodiment is as Figure 1 to Figure 4 As shown, one end of the handle 6 has a bagging box 5 with an opening facing upwards, and the four corners of the bagging box 5 are respectively equipped with a reset seat 2 that constitutes a vertical movement pair and a locking lever 22 with upper and lower limit positions. The reset seat 2 and the locking lever are all tending toward the upper limit position under the corresponding spring, and the electromagnetic sucker 20 fixed on the bagging box is installed under the locking lever; A group of bagging pins, the barbs at the inner end of the bagging pins hook the bag mouth that tends to be elastically folded; when the electromagnetic sucker 20 is de-energized, the locking lever is at the upper limit position to block the bagging pins, and the bagging It is in the open state of the bag opening; when the electromagnetic chuck 20 is energized, the locking rod is sucked to the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com