Caramel yoghourt preparing method

A caramel and yogurt technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of high storage conditions and poor stability, and achieve the effect of increasing the desire to buy and changing the flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

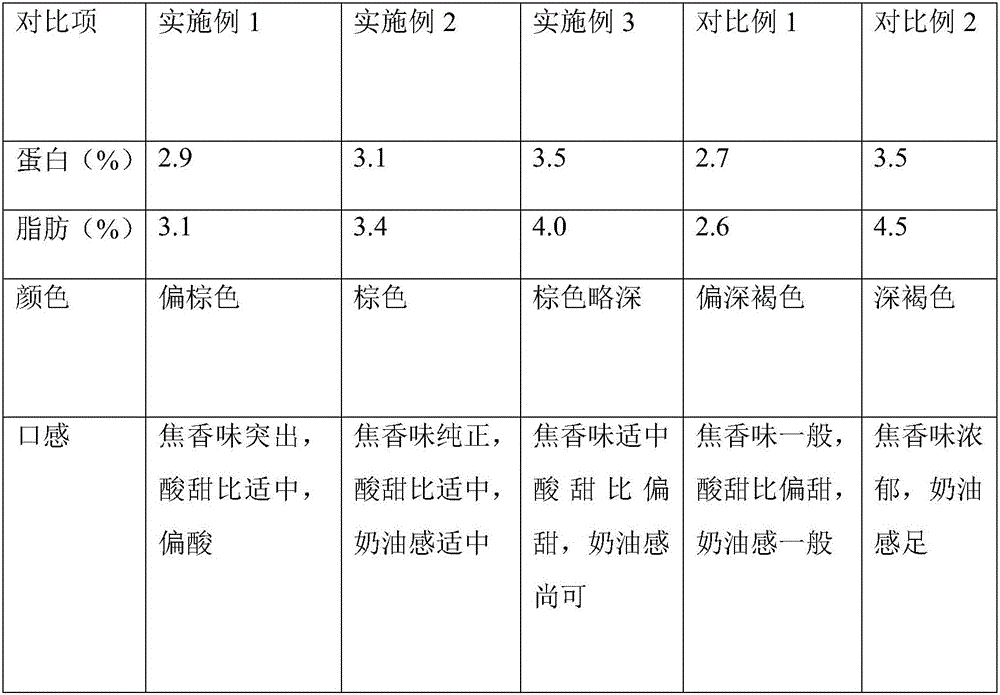

Examples

Embodiment 1

[0023] A method for making caramel yogurt, comprising the following steps:

[0024] Raw materials: in parts by weight, 80 parts of milk, 3-6 parts of glucose, 5 parts of white sugar, 0.5 parts of stabilizer, 0.2 parts of wpc whey protein powder, 5 parts of condensed milk, 1.4 parts of cream, 2 parts of caramel ;

[0025] Heat and stir the milk to 60°C, add glucose and white sugar, stir for about 6 minutes, add stabilizer, then add wpc whey protein powder, dissolve for about 10-15 minutes; add condensed milk, cream, fully dissolve for 15-20 minutes Minutes, add caramel, homogenize at 20Mpa, sterilize at 92-95°C for 300s, cool to about 40°C, inoculate strains Danisco’s direct injection strain 827 or Hansen’s direct injection strain 904, and place in a 42°C incubator Cultivate in medium for 5-8 hours, take it out and refrigerate at 2-8°C for post-cooking.

[0026] In the above formula:

[0027] Glucose: the most widely distributed and most important monosaccharide in nature, i...

Embodiment 2

[0036] Mix 70% of milk and glucose and heat to 60°C, stir and mix well, fully stir and mix 6% white sugar and 4‰ stabilizer, add to the base material, then add 4% condensed milk, wpc80 2‰, cream 1.8 %, continue to stir for 20 minutes, add 2.5% caramel and mix well, homogenize at 20Mpa, sterilize at 95°C for 10 minutes, then supercool to about 42°C to inoculate strains, ferment in 42°C thermostat for 7 hours, acidity When it reaches 75 degrees, it can be taken out to break the emulsification, and it can be cooked after refrigeration.

Embodiment 3

[0038] Mix milk 65% and glucose and heat to 55°C, stir and mix well, stir and mix 7% white granulated sugar and 3‰ stabilizer, add it to the base material, then add 3% condensed milk, wpc80 2‰, cream 2 %, continue to stir for 20 minutes, add 3% caramel and mix well, homogenize at 20Mpa, sterilize at 95°C for 10 minutes, then supercool to about 42°C to inoculate strains, ferment in a 42°C thermostat for 8 hours, the acidity When it reaches 75 degrees, it can be taken out to break the emulsification, and it can be cooked after refrigeration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com