Red pitaya pulp color-protecting processing method

A technology of red heart pitaya and a processing method, applied in the field of food processing, can solve problems such as no color protection treatment, and achieve the effects of improving market competitiveness, good stability, and beautiful color and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A. Wash the selected 2.5 tons of red dragon fruit with water, then disinfect and clean the surface of the dragon fruit with a chlorine dioxide disinfectant with a concentration of 20ppm to control the growth of microorganisms, and then rinse the dragon fruit with pure water to remove The residual disinfectant was peeled and squeezed to obtain 1.8 tons of pulp;

[0020] B, the squeezed pulp is subjected to high-temperature instantaneous sterilization, and after sterilization, it is separated by a high-speed centrifuge to obtain 1.37 tons of red dragon fruit pulp;

[0021] C. Add 0.3% D-sodium erythorbate and 0.3% sodium phytate to the dragon fruit pulp obtained above, stir well and then carry out casing-type sterilization at 98°C for 60s, and then cool naturally to obtain protected Red Heart Dragon Fruit Puree.

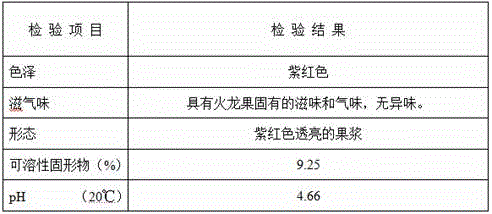

[0022] See the table below for the results of the red pitaya pulp test:

[0023]

Embodiment 2

[0025] A. Wash the selected 2 tons of red dragon fruit with water, then disinfect and clean the surface of the dragon fruit with a chlorine dioxide disinfectant with a concentration of 20ppm to control the growth of microorganisms, and then rinse the dragon fruit with pure water to remove The residual disinfectant was then peeled and squeezed to obtain 1.36 tons of pulp;

[0026] B, the squeezed pulp is subjected to high-temperature instantaneous sterilization, and after sterilization, it is separated by a high-speed centrifuge to obtain 0.94 tons of red dragon fruit pulp;

[0027] C. Add 0.5% sodium D-isoascorbate and 0.2% sodium phytate to the dragon fruit pulp obtained above, stir well and then carry out casing-type sterilization at 98°C for 85s, and then cool naturally to obtain protected Red Heart Dragon Fruit Puree.

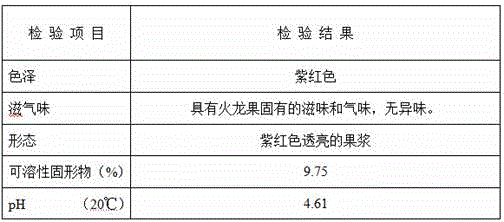

[0028] See the table below for the results of the red pitaya pulp test:

[0029]

Embodiment 3

[0031] A. Wash the selected 3 tons of red dragon fruit with water, then disinfect and clean the surface of the dragon fruit with a chlorine dioxide disinfectant with a concentration of 20ppm to control the growth of microorganisms, and then rinse the dragon fruit with pure water to remove The residual disinfectant was then peeled and squeezed to obtain 2.25 tons of pulp;

[0032] B, the squeezed pulp is subjected to high-temperature instantaneous sterilization, and after sterilization, it is separated by a high-speed centrifuge to obtain 1.49 tons of red dragon fruit pulp;

[0033] C. Add 0.8% sodium D-isoascorbate and 0.1% sodium phytate to the dragon fruit pulp obtained above, stir well and then carry out casing-type sterilization at 99°C for 90s, and then cool naturally to obtain protected Red Heart Dragon Fruit Puree.

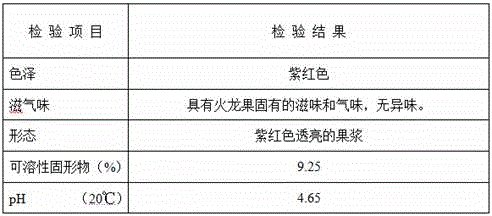

[0034] See the table below for the results of the red pitaya pulp test:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com