Waterproof shoes and production method thereof

A technology of waterproof shoes and waterproof shoe covers, which is applied in the field of shoes, can solve the problems of high luck, non-waterproof upper layer, and uncertain waterproof performance of waterproof shoes, etc., and achieve the effect of stable waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

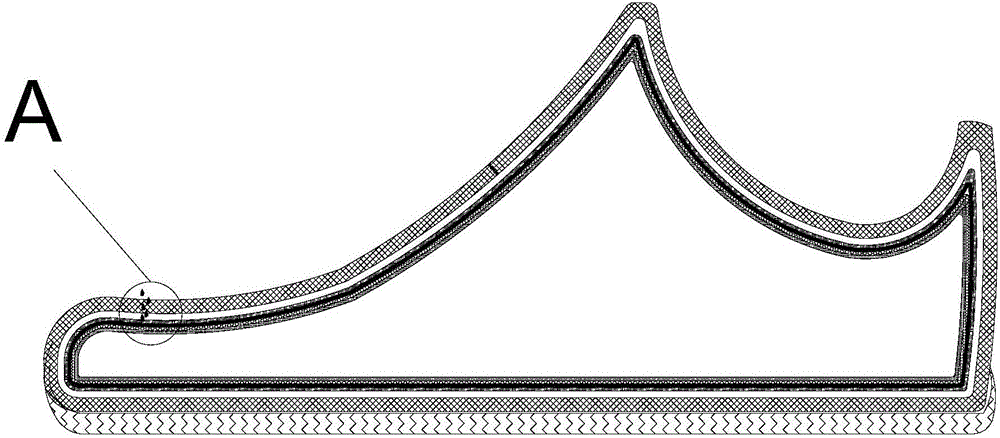

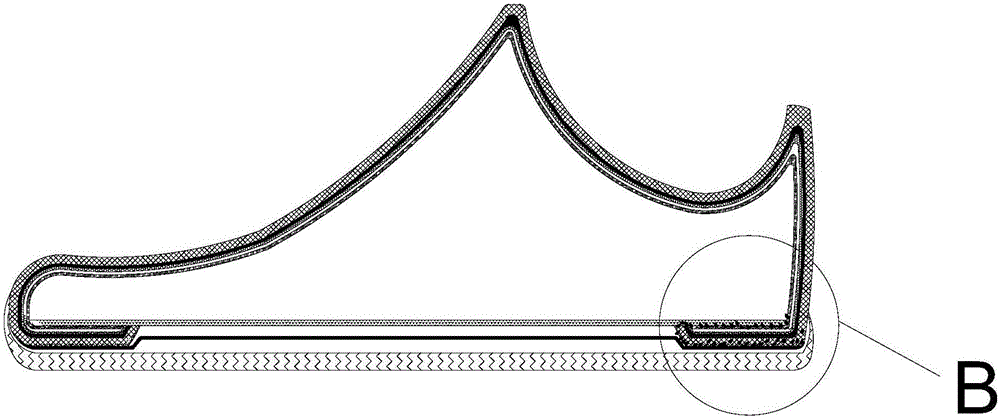

[0039] Figure 5 to Figure 9 A waterproof shoe according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a shoe sole 1 and a shoe body 2 fixed on the upper part of the shoe sole 1 .

[0040] Wherein, the shoe body 2 is mainly composed of a waterproof shoe cover 3 and an inner layer 4 .

[0041] The waterproof shoe cover 3 is composed of two or more waterproof material sheets 3a.

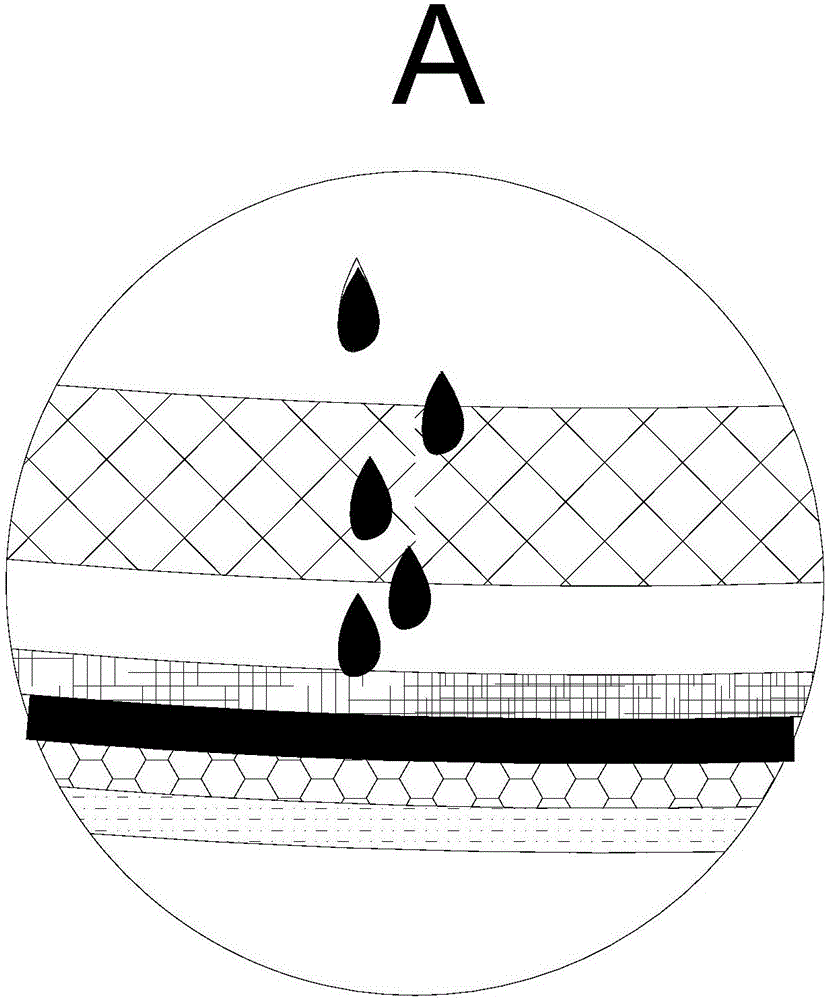

[0042] The waterproof material sheet 3 a is composed of a waterproof membrane 32 , a surface layer 31 and a nylon mesh layer 33 respectively attached to both sides of the waterproof membrane 32 .

[0043] Two or more sheets of waterproof material 3a are spliced into a three-dimensional shoe cover with the surface facing outwards by stitching.

[0044] A professional waterproof adhesive tape 5 is pasted on the joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com