A control method for multi-path warehousing of hot-rolled rolling line steel coils

A control method and multi-path technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of high error rate and low handling efficiency, achieve low cost, reduce stacking times, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

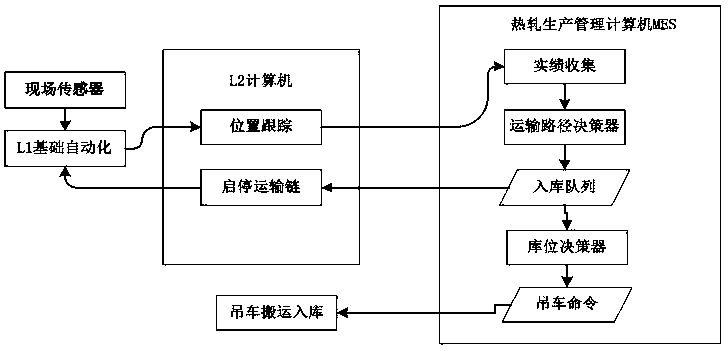

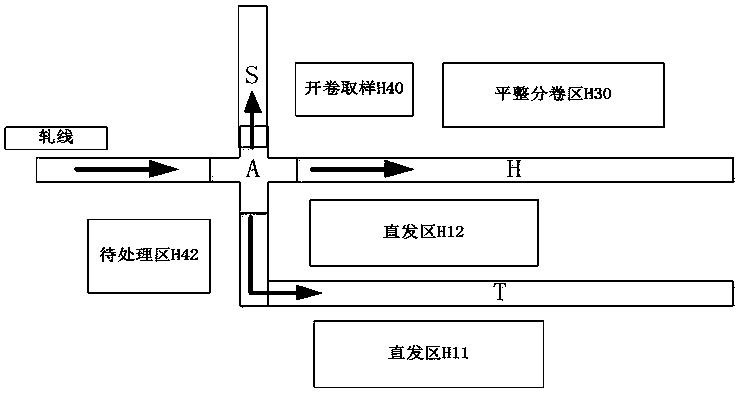

[0019] refer to figure 1 , figure 2 According to the present invention, the control method for multi-path warehousing of hot-rolled rolling line steel coils includes the following steps:

[0020] (1) Tracking of the location of the steel coils in the warehouse. The process computer rolling line coil off-line performance, tracking position and storage request information from the process control system (L2) are collected on the production management computer (MES) through text communication;

[0021] (2) The decision-making control of the transportation route, the production management computer (MES) establishes the optimal transportation route for steel coil handling, and sends the start-stop information of the transportation chain through the process computer of the process control system (L2);

[0022] (3) The decision-making control of the storage location, the production management computer (MES) establishes the destination storage location of the steel coil, the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com