Simple leveler

A leveling machine and simple technology, applied in the field of simple leveling equipment, can solve the problems of high purchase and use cost, low production efficiency, and high skill requirements for operators, and achieve the effects of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

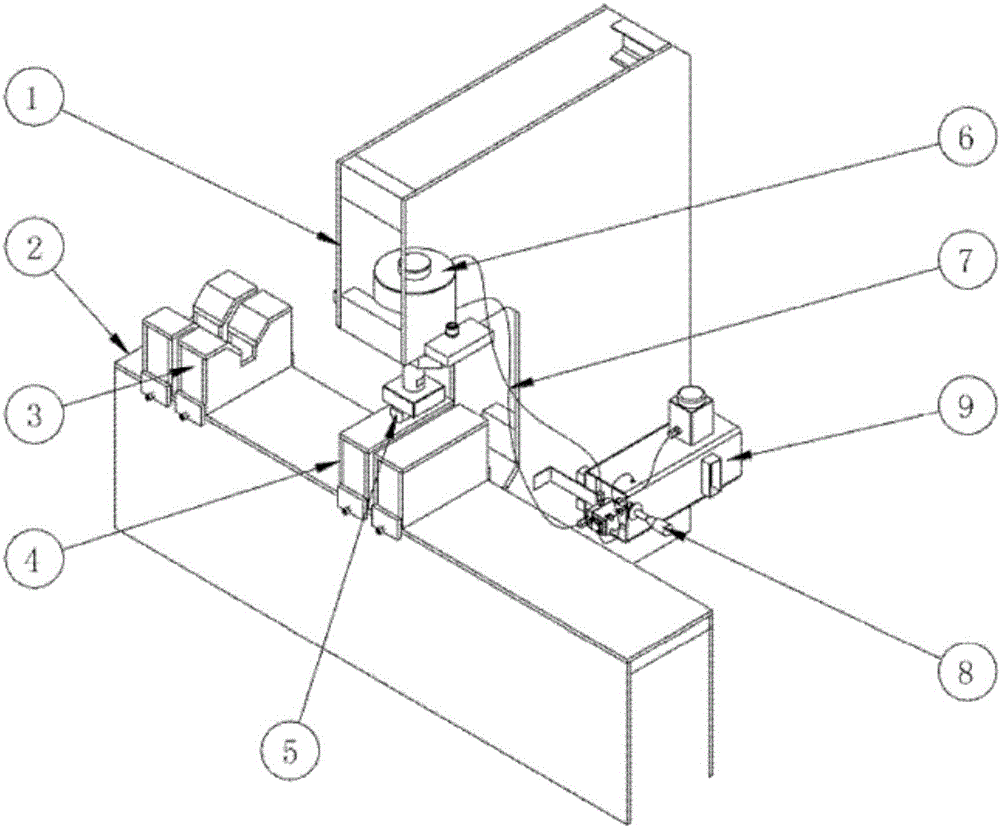

[0018] The invention provides a simple leveling equipment, its structure refers to the attached figure 1 As shown; the leveler is mainly composed of three functional parts:

[0019] Equipment frame part: It mainly includes frame 1 and workbench 2, which are welded by steel plates, and serve as the installation basis for functional parts such as oil pressure, and bear the load during the work process.

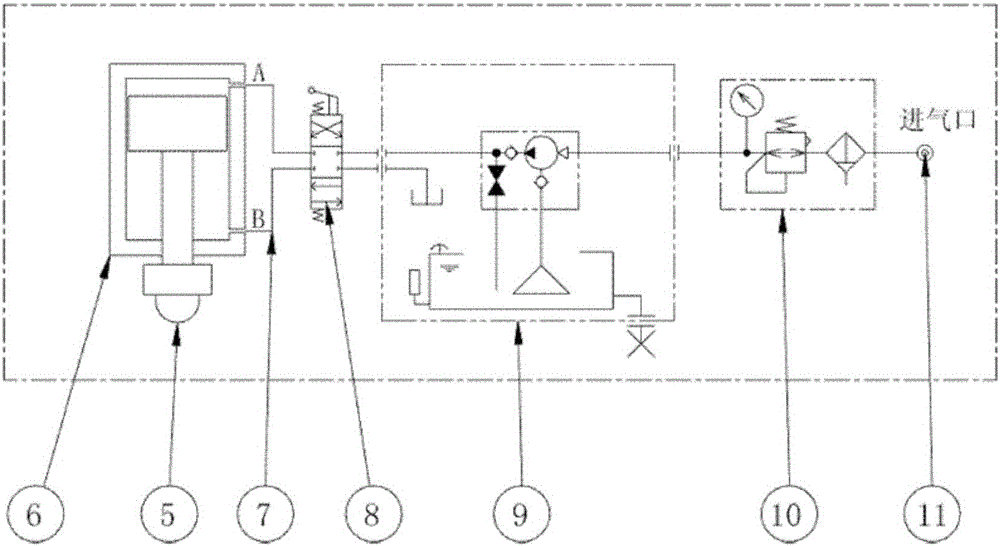

[0020] Oil pressure system part: mainly composed of oil cylinder 6, high pressure pipe 7, manual valve 8, pneumatic pump station 9, filter pressure reducing valve 10 and air source interface 11. This part converts air pressure into high pressure oil to drive the oil cylinder for leveling Operation.

[0021] Leveling tooling part: mainly includes V-shaped anvil 3, plane anvil 4, and indenter 5. The indenter part is made into a corresponding shape such as semicircle or obtuse angle according to the needs of leveling operations. The plane anvil is suitable for plate straightening,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com