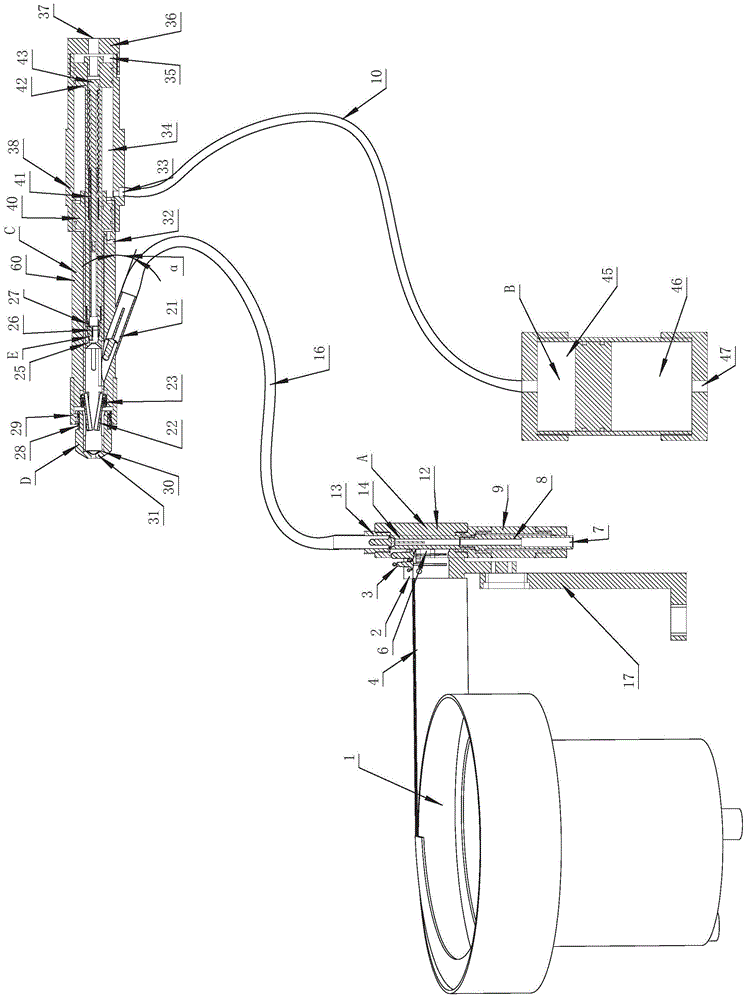

Full-automatic riveting device and method

A riveting device and fully automatic technology, which is applied in the field of riveting devices for automatic nail feeding, riveting and core pulling, can solve the problems of low work efficiency, difficulty in popularization, and high cost, so as to reduce the intensity of manual labor, meet industrial needs, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

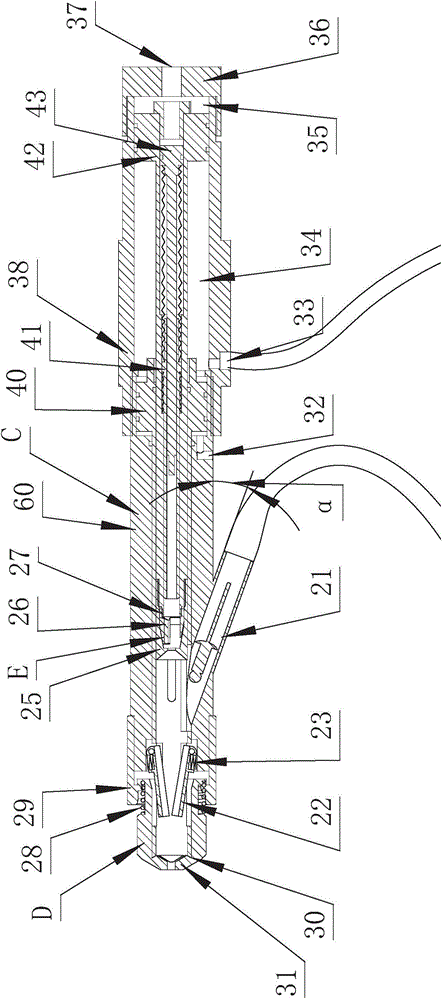

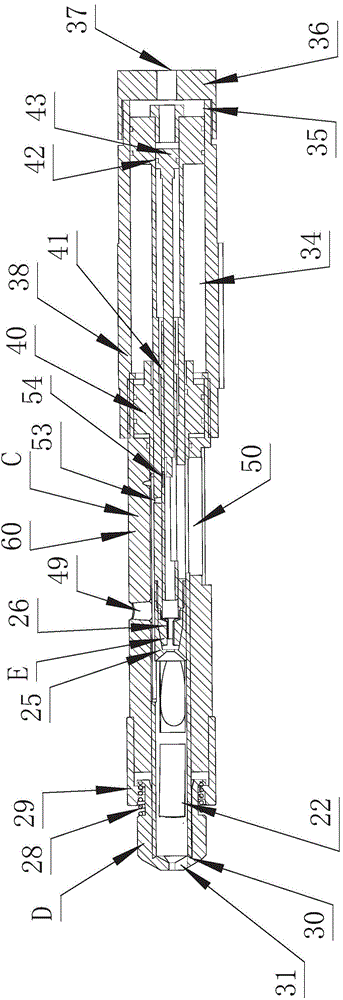

[0039] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0040] After long-term and in-depth research, the present inventor has provided a fully automatic riveting device that can automatically complete the retrieving and riveting. The device can automatically feed nails, rivet, and core without manual operation. , light and flexible, suitable for different parts and different applications, so as to reduce the intensity of manual labor and improve work efficiency to meet the continuously developing industrial needs. Based on the above findings, the inventors have accomplished the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com