Automobile front axle casting mold with connecting terminal reversing head and automobile front axle manufacturing method

A terminal block and automobile front axle technology, which is applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of high noise and achieve the effect of low noise and not easy to cause bad electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

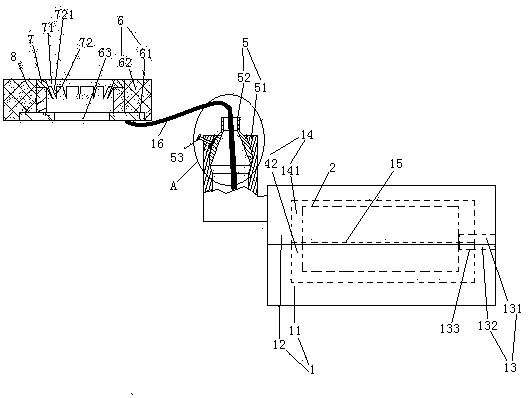

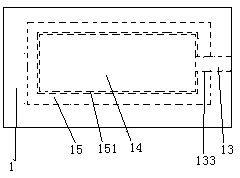

[0044] Embodiment one, see figure 1 , a kind of automobile front axle casting mold with connection terminal reversing head, including reversing head 5, connection terminal 6 and steel mold body 1. The mold body 1 is provided with a casting port 13 . The mold body 1 includes an upper mold 11 and a lower mold 12 . A front shaft cavity 14 is provided in the upper mold 11 and the lower mold 12 . A front axle model support piece 15 is provided in the front axle cavity 14 . The front axle model support sheet 15 is connected together with the upper mold 11. The pouring port 13 is surrounded by an upper half 131 arranged on the upper mold 11 and a lower half 132 arranged on the lower mold 12 . The inner end of the casting gate 13 is provided with a gate inner convex part 133 protruding from the front axle cavity 14 .

[0045] The reversing head 5 includes a base pipe 51 and a reversing pipe 52 . The base pipe 51 is fixed together with the upper mold 11 . The power line 16 passe...

Embodiment 2

[0057] Embodiment two, the difference with embodiment one is:

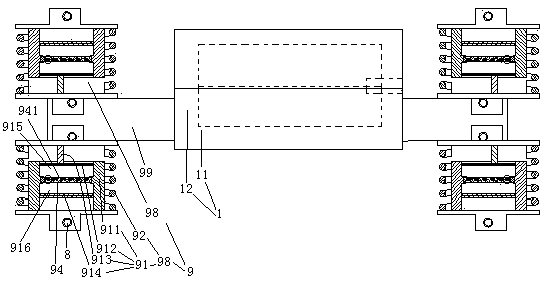

[0058] see image 3 , The two ends of the lower mold of the mold body 1 are respectively provided with a connecting ear 99 . Connecting ear 99 is connected with shock-absorbing suspension frame 9. The shock-absorbing suspension frame 9 includes a pair of shock-absorbing connectors 98 arranged oppositely along the vertical direction. The damping connector 98 includes a vertical damping cylinder 91 and a damping spring 92 sleeved on the damping cylinder. The damping oil cylinder 91 includes a damping oil cylinder body 911 . The damping cylinder body 911 is provided with a first piston 912 , a second piston 914 and a separation plate 94 . . The first piston 912 is connected with a piston rod 913 . One end of the damping spring 92 is affixed together with the piston rod 913, and the other end is affixed together with the cylinder body 911 of the damping oil cylinder. Both the damping cylinder body 911 and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com