Solid electrolytic capacitor and method of manufacturing same

A technology of solid electrolysis and capacitors, which is applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of insufficient strength, bending of belt part 163, etc., and achieve the effect of improving productivity and not being easy to connect badly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

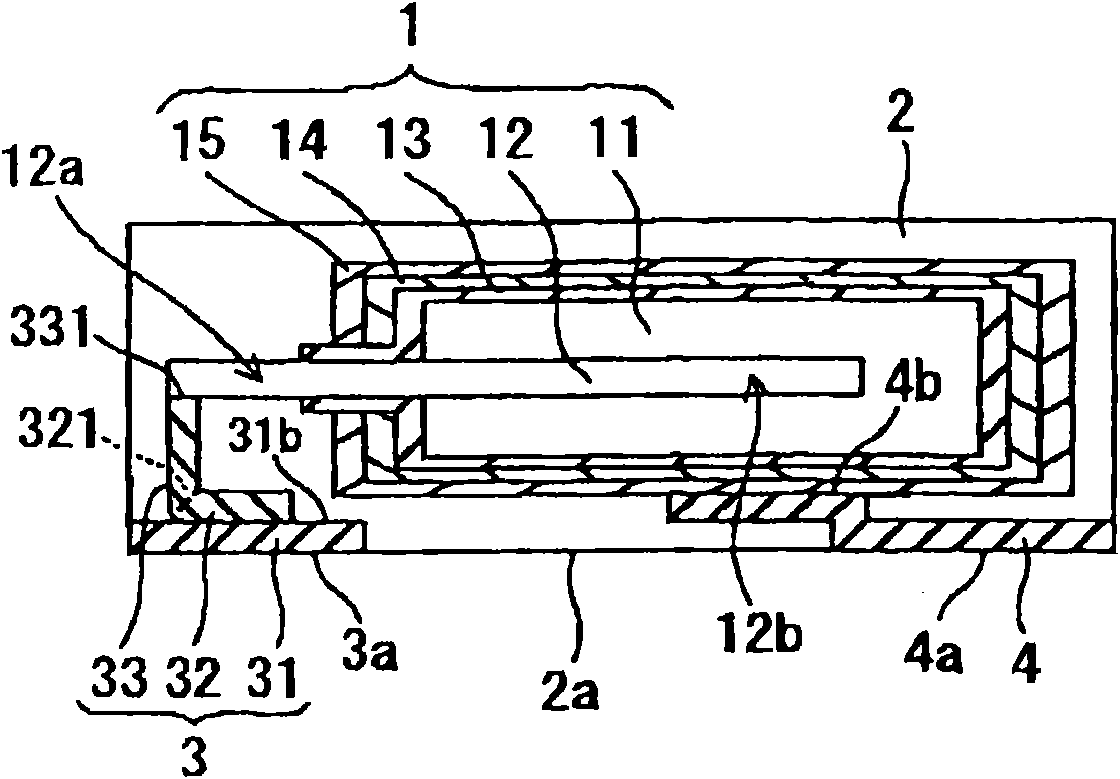

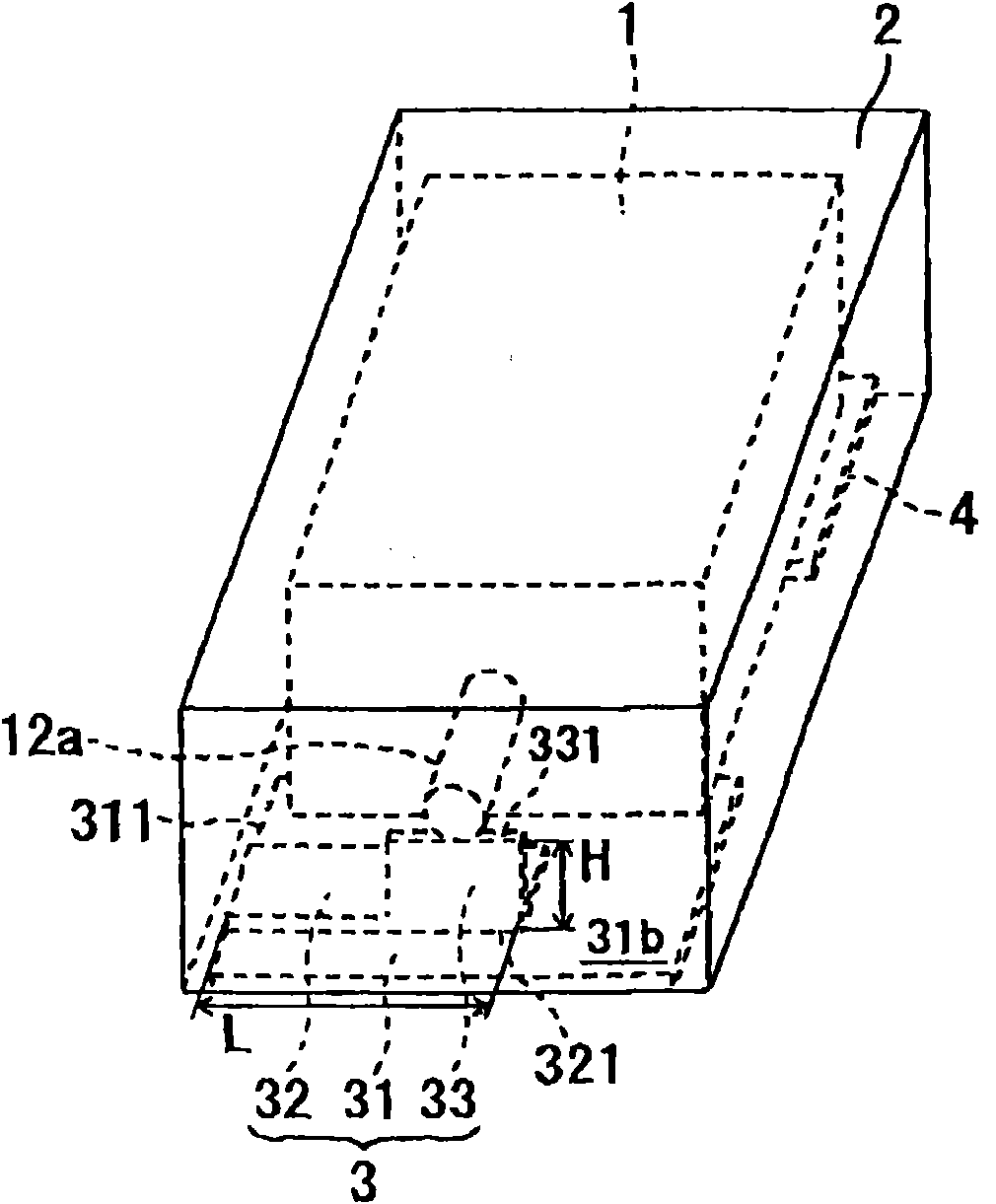

[0045] like figure 1 and figure 2 As shown, the solid electrolytic capacitor according to the embodiment of the present invention has: a capacitor element 1 ; an encapsulating resin 2 covering the capacitor element 1 ; an anode terminal 3 ; and a cathode terminal 4 .

[0046] like figure 1 As shown, the capacitor element 1 is composed of an anode body 11 , an anode lead 12 , a dielectric layer 13 , an electrolyte layer 14 , and a cathode layer 15 .

[0047] The anode body 11 is composed of a porous sintered body made of a metal having a valve action. As the metal having valve action, tantalum, niobium, titanium, aluminum, etc. can be used, for example.

[0048] In the anode lead 12 , the front end portion 12 a protrudes forward from the anode body 11 , and the base end portion 12 b is embedded in the anode body 11 . The anode lead 12 is made of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com