Gear ring support machining technique

A processing technology and technology of a ring gear, applied in the field of processing technology of a ring gear bracket, can solve the problems of high production cost, time-consuming and laborious, large consumption of raw materials for processing technology, long production process, etc., and achieves simple processing process and good wear resistance. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

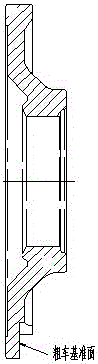

[0020] Below in conjunction with accompanying drawing, the present invention is further described;

[0021] A ring gear bracket processing technology, the processing technology includes the following steps:

[0022] 1) Rough inspection:

[0023] 2) Rough turning: a. The outer circle of the big head of the three-jaw clamp, the size of each gear of the small head of the rough turning, pay attention to the rough turning with the upper notch surface of the blank as the rough reference to distribute the rough turning allowance to both sides, and the spindle speed is 250r / min , the feed rate is 0.3mm / r; b, the U-turn clamp is the inner hole of the small head, and the dimensions of each gear of the large head are roughed (note that the error of the two clampings is not greater than 0.4mm), and the spindle speed is 250r / min, and the feed rate is 0.3mm / r; c, deburring, inspection, qualified storage.

[0024] 3) Quenched and tempered shot blasting: a. Quenched and tempered: 25~30HRC,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com