Auxiliary tool for machining B type gamma knife treatment head part and machining method

A technology for auxiliary tooling and treatment head, which is applied in the direction of metal processing machinery parts, metal processing equipment, positioning devices, etc., can solve the problems of large accumulation error, large matching contact area, and shrinking application range, so as to reduce processing error and error accumulation , improve assembly quality and efficiency, and save processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

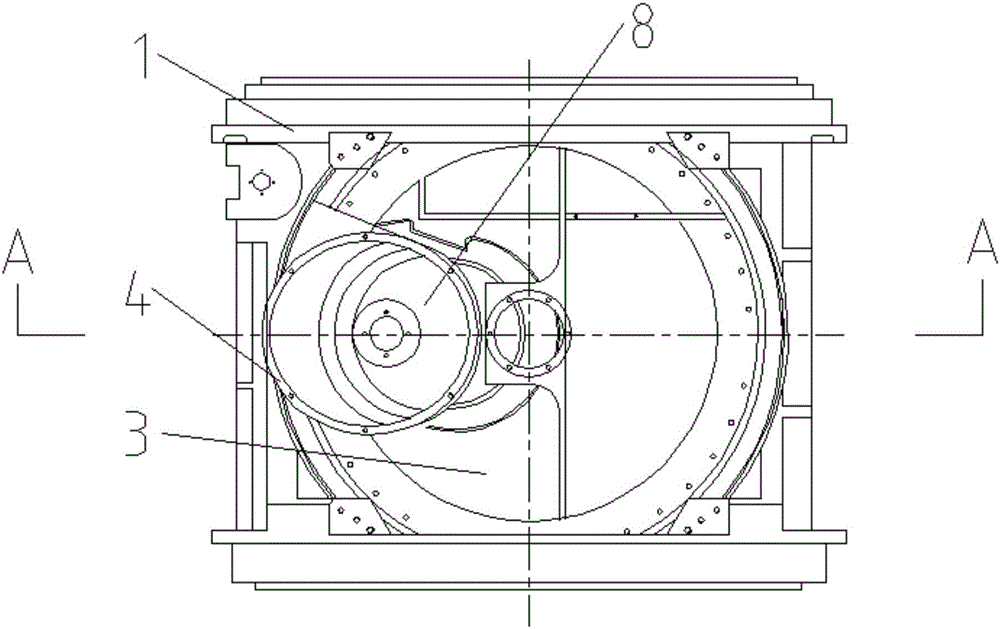

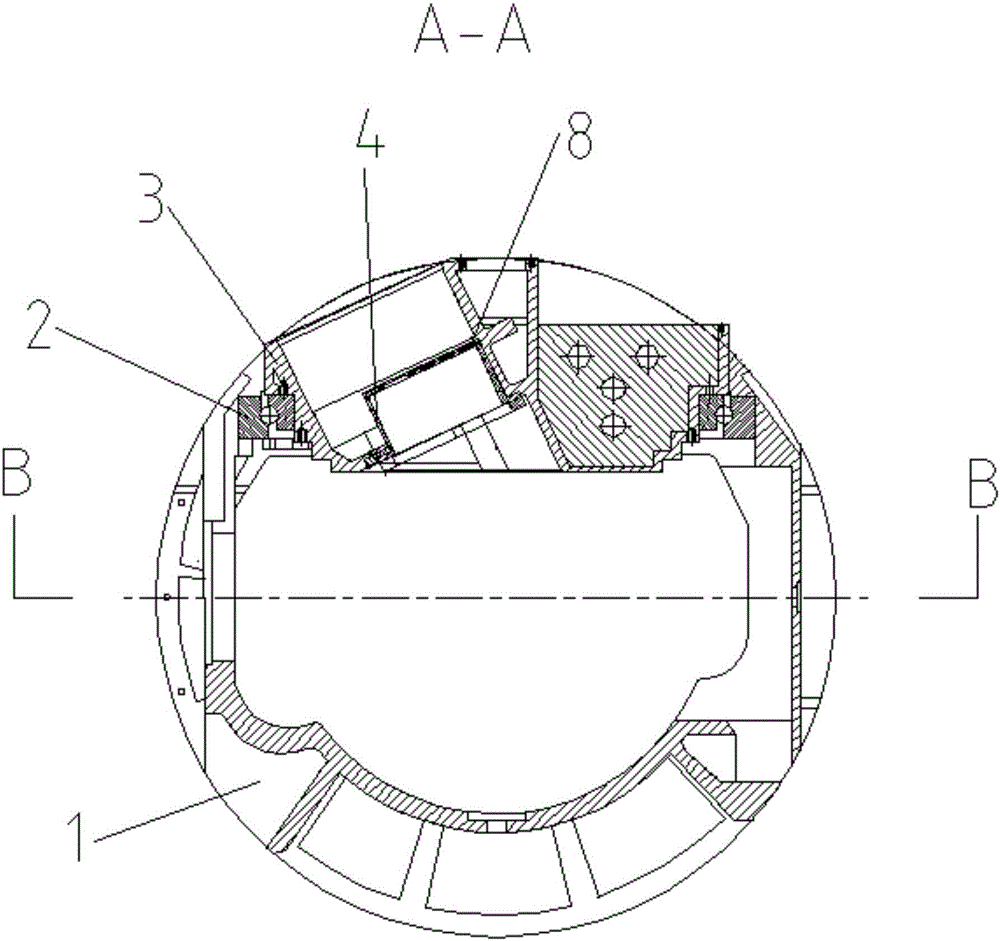

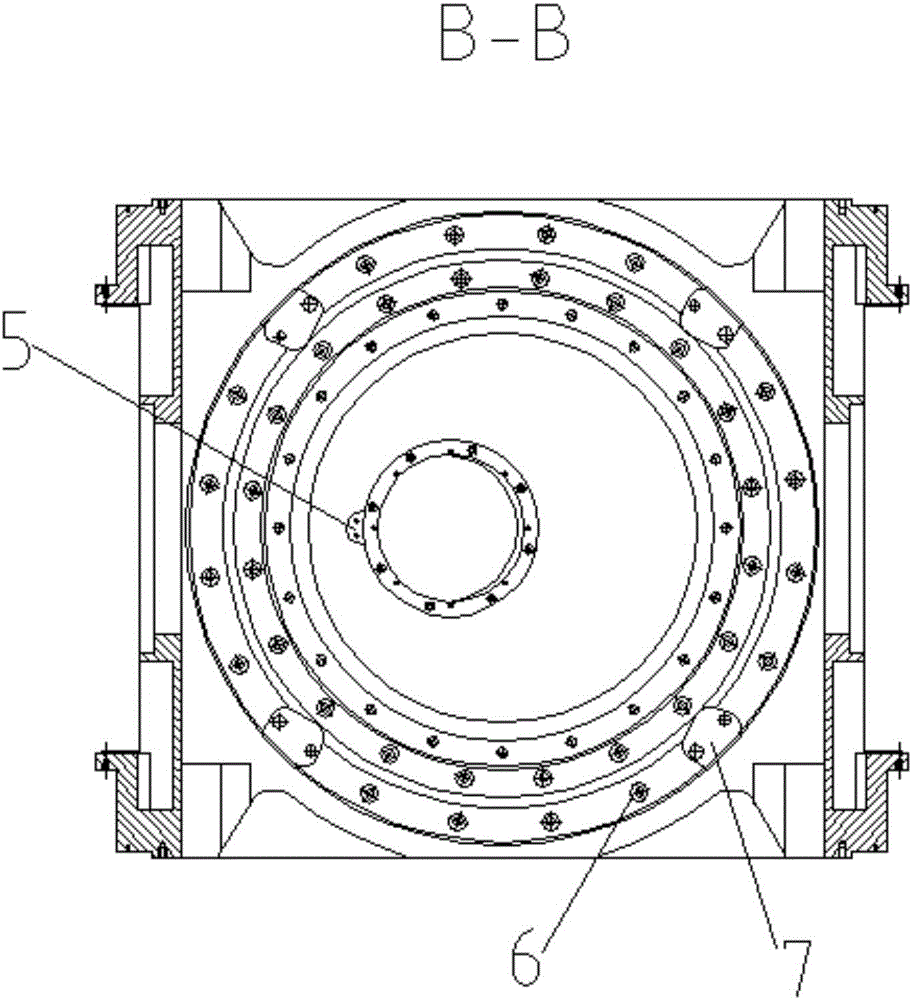

[0042] Such as figure 1 , figure 2 and image 3The shown auxiliary tooling for processing B-type gamma knife treatment head parts includes a cylinder 1 and a rotating disk 3, the central axis of the cylinder 1 is perpendicular to the central axis of the rotating disk 3, and the cylinder 1 A rotating disk bearing 2 is arranged between the rotating disk 3, the outer ring of the drum 1 and the rotating disk bearing 2 is fixed by bolts, the rotating disk 3 and the inner ring of the rotating disk bearing 2 are fixed by bolts, and the rotating disk 3 is provided with a processing hole for processing the B-type Gamma Knife treatment head parts, and the bottom of the processing hole is provided with a mounting hole for clamping the B-type Gamma Knife treatment head parts. The centerlines of the drum 1 are vertically intersected, and the centerline of the mounting hole is provided with a fixed block 7 for preventing the inner ring and the outer ring of the rotating disk bearing 2 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com